Heat supply system and method meeting high-parameter need of heat consumer

A technology for heating systems and heat users, applied in pipeline systems, superheated temperature control, steam superheating, etc., can solve the problems of high-quality steam energy waste, heating flexibility constraints, and increased renovation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

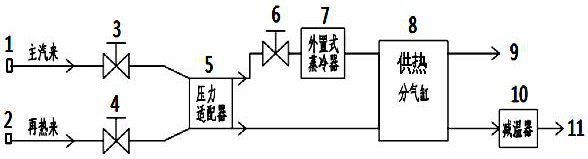

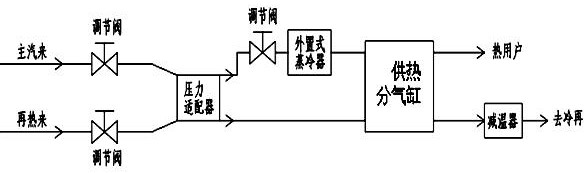

[0028] Such as figure 1 As shown, the heating system of the present invention that meets the needs of high-parameter heat users includes a pressure adapter 5, an evaporator cooler 7, and a heating sub-cylinder 8. The main steam heat supply interface 1 leads the main steam through the flow regulating valve 3 and reheat steam The reheated steam from the heat supply interface 2 enters the pressure adapter 5 through the flow regulating valve 4 for mixing. The pressure after mixing must meet the pressure demand of the heat user. Therefore, the opening of the above two flow regulating valves 3 and 4 is determined by the pressure demand of the heat user. It is determined that the main steam flow through the flow regulating valve 3 can adopt the T26 electronic electric single-seat regulating valve. The outlet of the pressure adapter 5 is divided into two paths, one path directly enters the heating sub-cylinder 8 through the flow regulating valve 6, and the other path leads into the ex...

Embodiment 2

[0030] The heat supply method of the present invention that meets the needs of high-parameter heat users is realized by the system of Embodiment 1, including the following steps:

[0031] Such as figure 1 The heat supply system shown to meet the needs of high-parameter heat users mainly includes a pressure adapter 5 , an evaporator cooler 6 and a heat supply sub-cylinder 8 .

[0032] Process flow of the present invention such as figure 2 As shown, the main steam and the reheated steam are sent to the pressure adapter 5. After being mixed and adjusted by the pressure adapter 5, one path is heated by the external steam cooler and sent to the heating sub-cylinder 8, and the other path is directly sent to the The heat supply sub-cylinder 8; after the two lines are mixed and adjusted in the heat supply high-pressure cylinder 8, one line is supplied to the heat user, and the other line is sent back to the cold section of the reheater through the desuperheater to maintain the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com