Coal rock three-dimensional strain field visualization system and method under complex geological structure

A technology of complex geology and strain field, used in instruments, mechanical devices, teaching models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

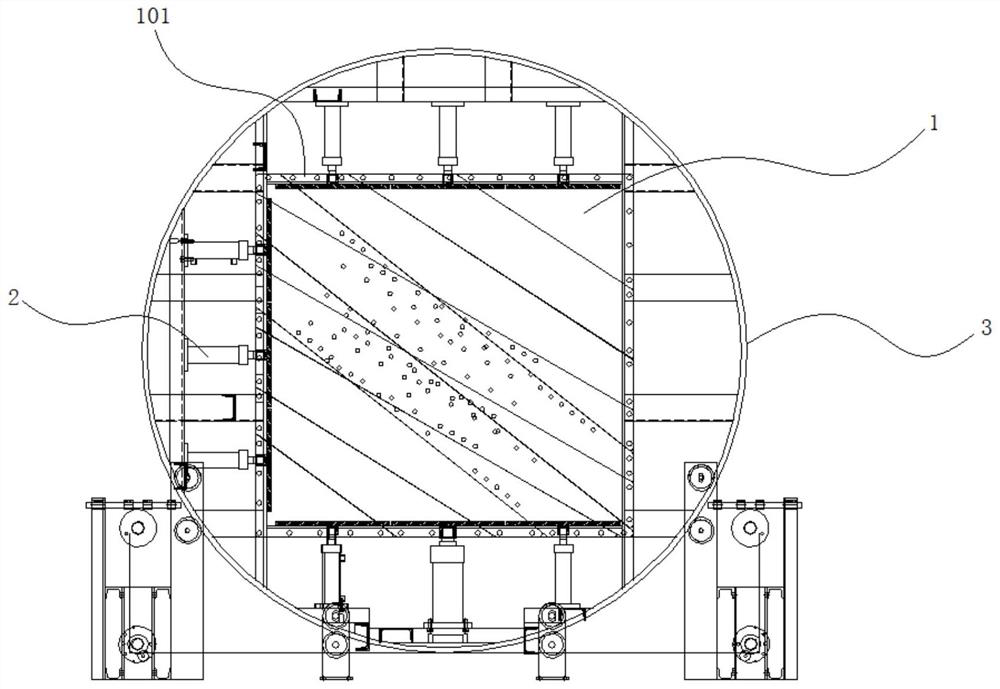

[0035] see Figure 1 ~ Figure 4 , this embodiment discloses a three-dimensional strain field visualization system for coal and rock under complex geological structures, including a stress condition simulation system and a strain monitoring system.

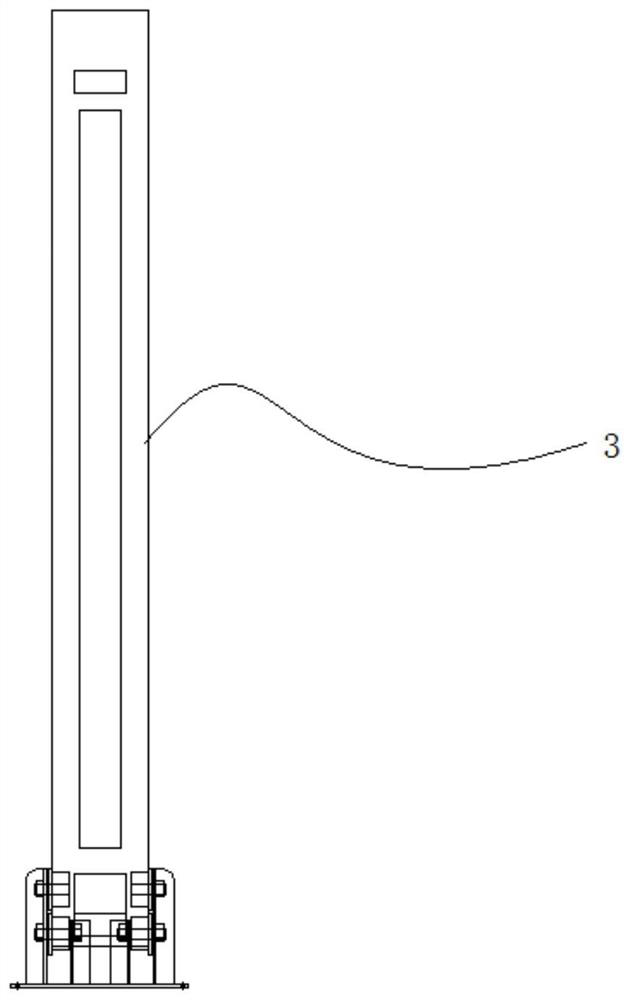

[0036] The stress condition simulation system includes a similar simulation experiment frame 1 , a loading system 2 and a circular slideway 3 .

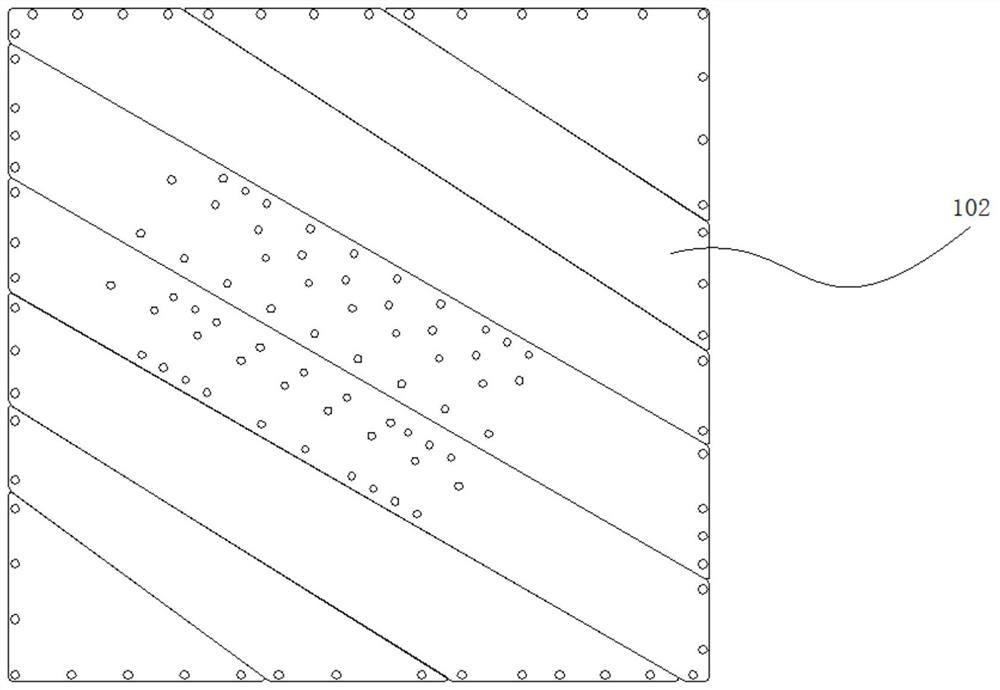

[0037] The similar simulation experiment frame 1 includes a pressure chamber 101 and two visualization side panels 102 . The pressure chamber 101 is a rectangular frame as a whole. Openings at both ends of the rectangular frame are blocked by the visible side panels 102 . The pressure chamber 101 and the visualization side panel 102 enclose a model placement cavity.

[0038] The loading system 2 includes a vertical axial compression loading system and a horizontal stress loading system. The vertical axial pressure loading system loads a set vertical loading force on the top and bottom...

Embodiment 2

[0042] see Figure 4 , this embodiment discloses a method for visualizing the three-dimensional strain field of coal and rock under complex geological structures using the system described in Embodiment 1, including the following steps:

[0043] 1) Heat and melt the transparent base material and evenly mix it with ink microcapsules to prepare 3D printing filaments. The wall of the ink microcapsule is made of polyurethane material, and the core of the capsule is made of dyed ink. The transparent base material adopts organic silicon resin.

[0044] In this embodiment, the ink microcapsules are synthesized by chemical method. Chemical method, also known as in-situ polymerization method, refers to adjusting the temperature, pH value of the reaction system or adding electrolytes, catalysts and a series of reaction conditions, so that small monomer molecules polymerize to form polymer film-forming materials, and precipitate out of the solution , wrap the core material. In the wh...

Embodiment 3

[0055] The main steps of this embodiment are the same as those in Embodiment 2, wherein, in step 4), a larger stress is applied on the left side of the top of the coal seam, and a larger stress is applied on the right side of the bottom, acting on the model as the main shear stress, so that the model is in the shear stress. Faults are generated under the action of stress, simulating the situation near the fault geological structure of coal and rock mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com