Injection microemulsion preparation system and method

A technology for preparing systems and injections, which is applied in the direction of making drugs into special physical or ingestible devices, other household appliances, household components, etc., which can solve the problems of insufficient microemulsion preparation, targeted control of injections, and packaging Problems such as poor transmembrane transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

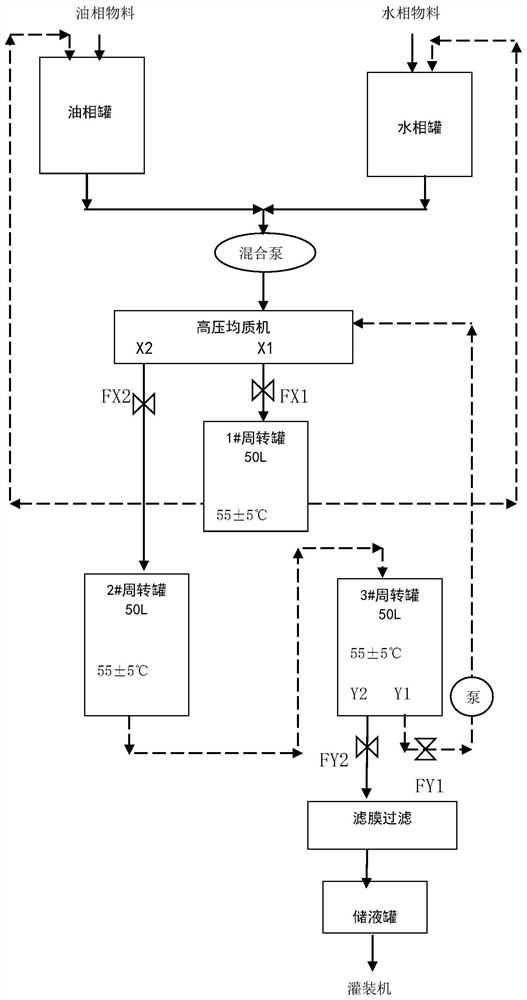

[0025] figure 1 Schematic diagram of the system for the preparation of microemulsions for injection.

[0026] Such as figure 1 As shown, the flurbiprofen axetil injection microemulsion preparation system includes: including oil phase tank, water phase tank, mixing pump, high pressure homogenizer, 1# turnover tank, 2# turnover tank, 3# turnover tank and liquid storage Can.

[0027] The oil phase tank has a built-in stator rotor dispersing and stirring device, and a jacketed container outside, which plays the role of two-phase mixing and homogenization. The water phase tank has a built-in stirring device and a jacketed container for uniform mixing. The high-pressure homogenizer makes the material in the suspension state flow through the cavity with a special internal structure at high speed under the action of ultra-high pressure, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com