Double-channel semi-automatic film coating forming machine and method

A semi-automatic, molding machine technology, applied in the direction of making medicines into special physical or taking form devices, other household appliances, household components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

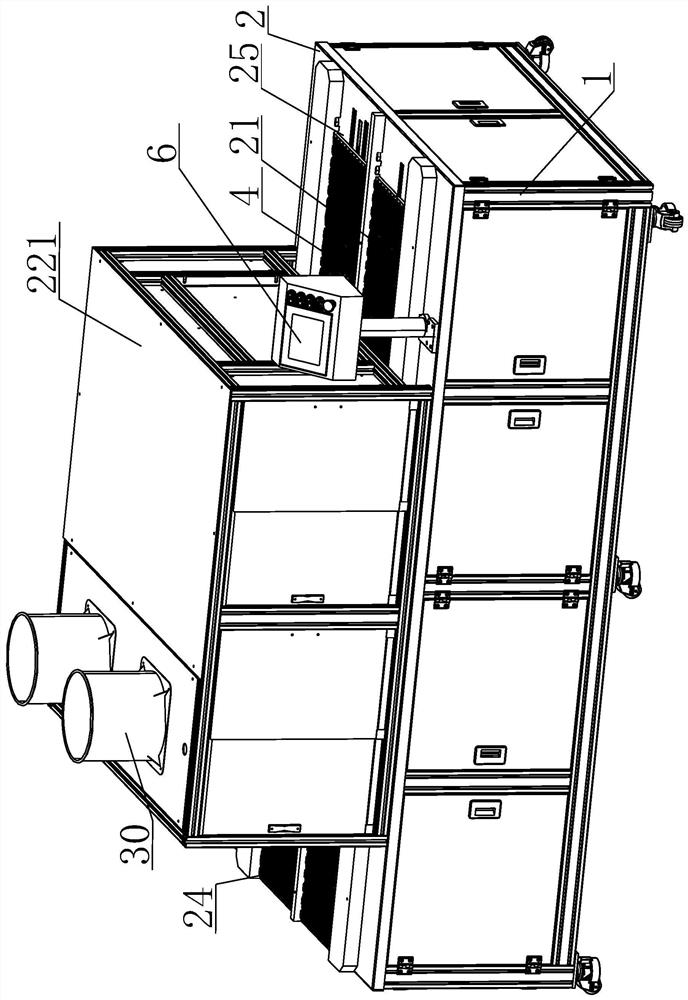

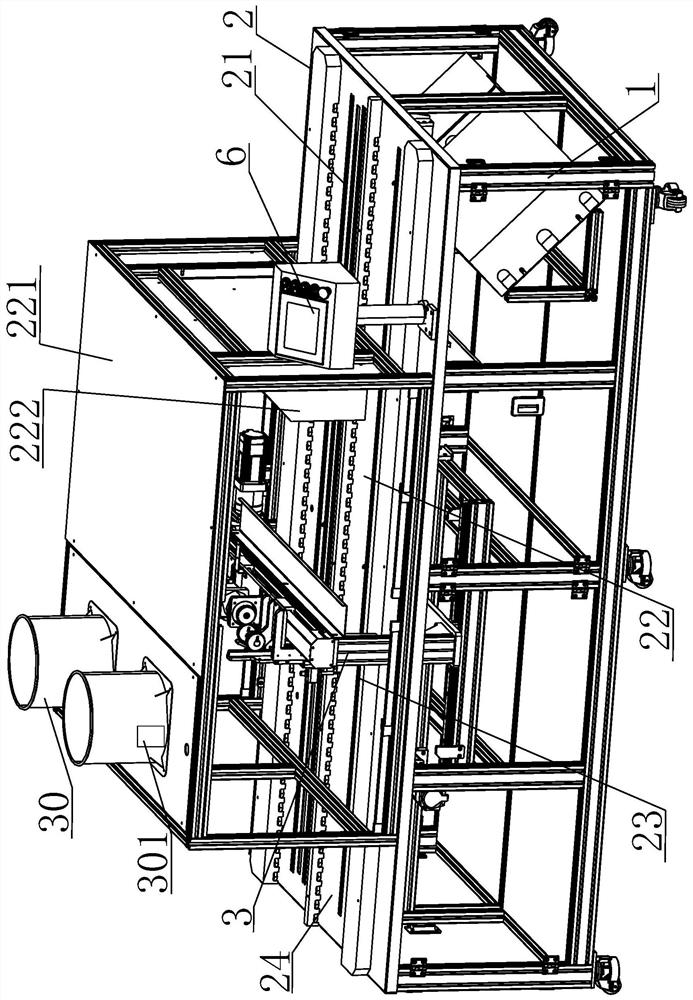

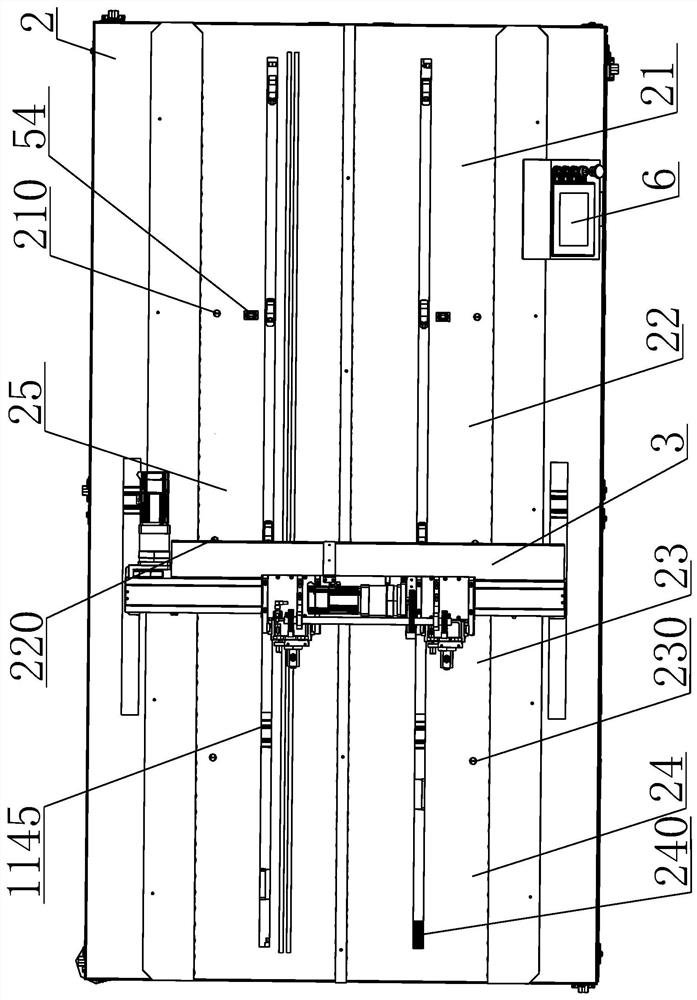

[0066]A double-channel semi-automatic film forming machine, including a frame 1, at least one set of guide grooves I25 for guiding the jig plate 4 is provided on the top platform 2 of the frame 1, and the platform 2 is from the head end to the end It is divided into a jig placement area 21 for placing the jig plate 4, a heating area 22 for preheating the jig plate 4, an operation area 23 for filling the jig plate 4, and a recycling and filling area. The operation completion area 24 of the rear fixture plate 4; the bottom of the platform 2 is provided with a fixture plate transmission unit for providing transmission power for the fixture plate 4; Dustproof cover 221, the inner wall of the dustproof cover 221 corresponding to the heating zone 22 is provided with a hot air blower 222; Filling unit3. The guide grooves I 25 are divided into two groups, and a set of fixture plates 4 are respectively arranged inside the two groups of guide grooves I 25 . The mobile filling unit 3 i...

Embodiment 2

[0082] A kind of double channel semi-automatic film forming machine, its structural part is identical with embodiment 1, and its difference is only: described cartridge 30 is provided with heating device 301, and heating device 301 is a steam heat exchange coil.

[0083] A method for a double-channel semi-automatic film forming machine, its method is the same as that of embodiment 1, and its difference is only: start the heating device 301 simultaneously to heat the material in the cartridge 30; start the hot air blower 222 in the heating zone 22 to The dustproof cover 221 is preheated, the material in the cartridge 30 is heated to 50°C, and the temperature inside the dustproof cover 221 is heated to 50°C.

Embodiment 3

[0085] A kind of double channel semi-automatic film forming machine, its structural part is identical with embodiment 1, and its difference is only: described cartridge 30 is provided with heating device 301, and heating device 301 is heat-conducting oil heat exchange coil.

[0086] A method for a double-channel semi-automatic film forming machine, its method is the same as that of embodiment 1, and its difference is only in: step 1: start heating device 301 simultaneously to heat the material in cartridge 30; Start the heat in heating zone 22 The fan 222 preheats the inside of the dust cover 221, the material in the cartridge 30 is heated to 55°C, and the temperature inside the dust cover 221 is heated to 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com