Desulfurization mother liquor spray drying method and desulfurization mother liquor spray drying device

An atomization drying and mother liquor technology, applied in the field of desulfurization mother liquor spray drying, desulfurization mother liquor spray drying device field, can solve the problems of water vapor condensation fog, affecting the desulfurization effect, COD and chloride ion cycle concentration and enrichment, etc., to achieve investment Low, simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

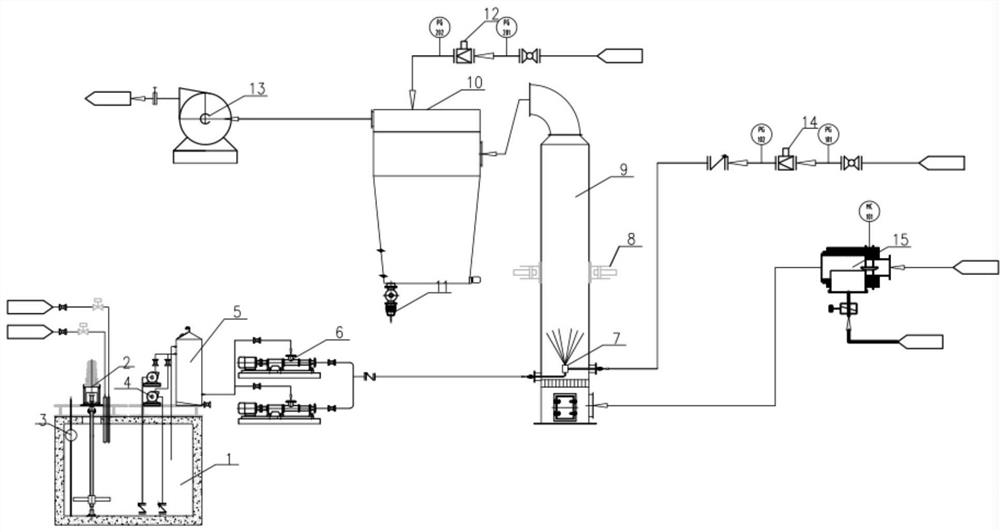

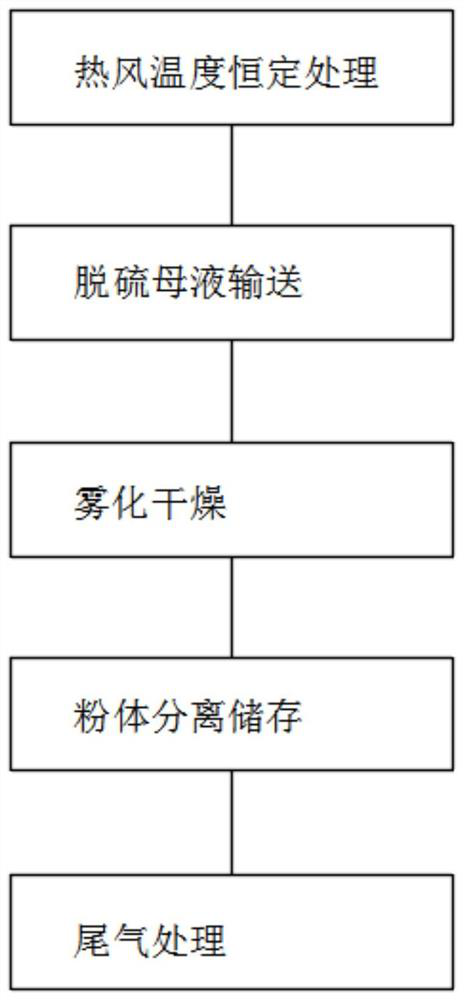

[0024] The present invention provides a technical solution: a method for spray drying desulfurization mother liquor and a device for spray drying desulfurization mother liquor. The high-temperature flue gas at 850°C is extracted from the upper part of the thermal storage oxidation device and the low-temperature tail gas at 160°C extracted from the outlet pipe of the thermal storage oxidation is separated. After adjusting the valve to adjust the flow rate, it enters the mixer 15 and mixes it into 350°C hot air for atomization and drying. The opening of the 850°C high-temperature flue gas adjustment valve and the 160°C tail gas adjustment valve are automatically controlled by PLC according to the temperature of the mixed hot air to ensure the mixed hot air When the temperature is constant, when the liquid level of the desulfurization mother liquor blending pool 1 is at the lower liquid level meter 3, the PLC controls the desulfurization mother liquor feed valve to open the desulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com