Microcapsule preparation device

A preparation device and microcapsule technology, which is applied in the field of microcapsule preparation devices, can solve problems such as difficult control of droplet size and drop speed, difficult quality assurance, and large differences in microcapsules, so as to achieve easy control of the production process and high production efficiency. High and simplified production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is further described in detail through specific implementation methods:

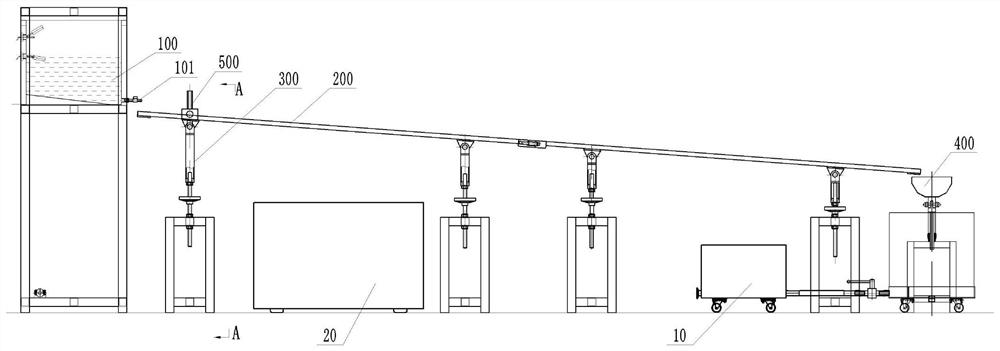

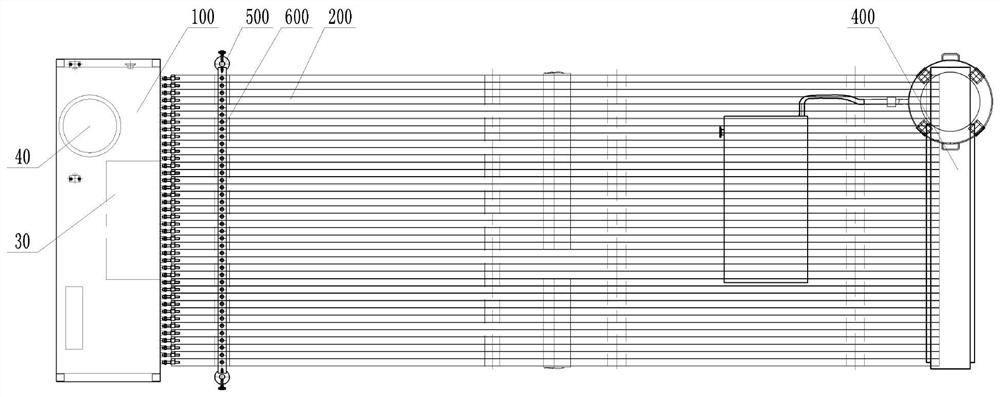

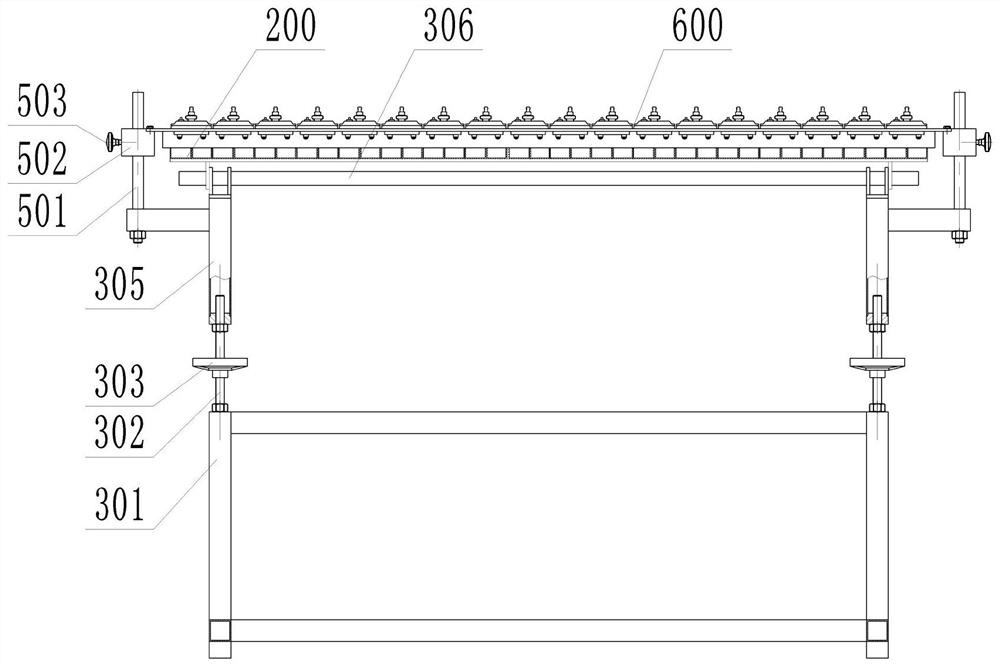

[0037] The embodiment is basically as attached figure 1 Shown: a microcapsule preparation device, including a heat preservation system, a drop material system 600, a conveying molding system and a collection system, the heat preservation system keeps the gel solution in a liquid state, and the drop material system 600 processes the gel solution into droplets and Transported to the conveying molding system, the liquid is reacted and formed into microcapsules in the conveying molding system, and the collection system separates and collects the microcapsules and coating liquid.

[0038] The microcapsule preparation device also includes a frame that provides support for the heat preservation system, the dripping system 600 and the conveying molding system or the components in the aforementioned systems, wherein the heat preservation system includes a heat preservation bucket 40, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com