Reciprocating type gear processing machine of gear shaft integrated piece

A reciprocating and processing machine technology, applied in the direction of gear cutting machines, components with teeth, metal processing equipment, etc., can solve the problems of scrapped workpieces, low machining accuracy, and easy breakage of gear cutting tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

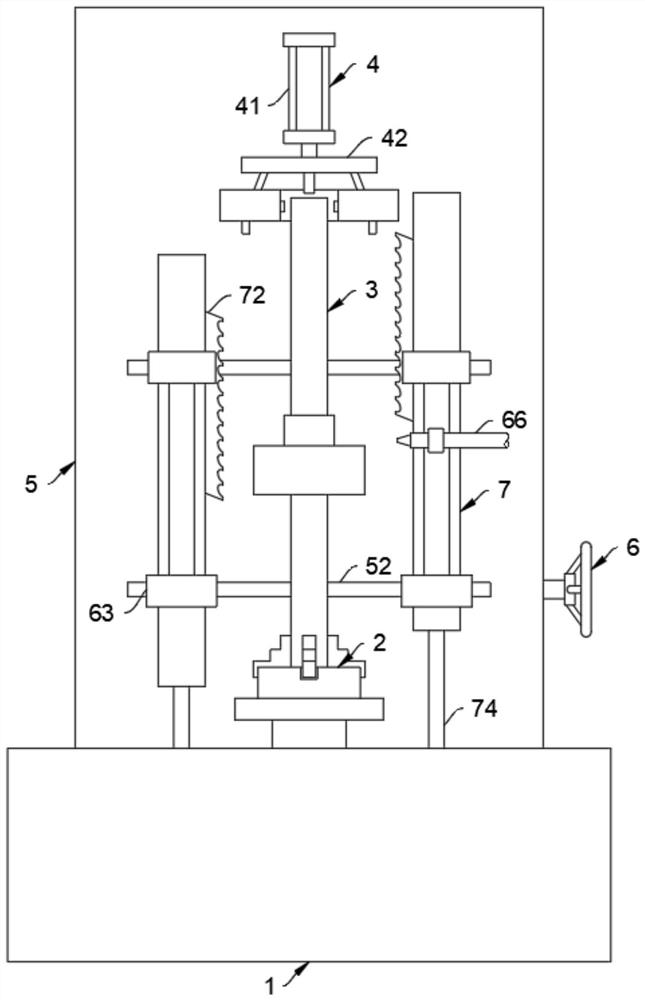

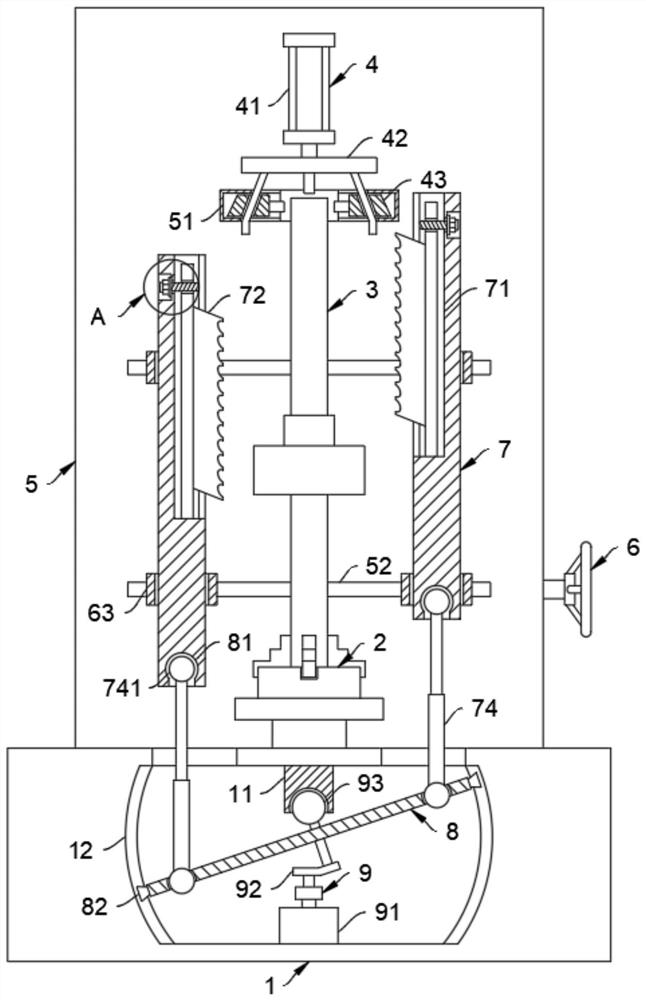

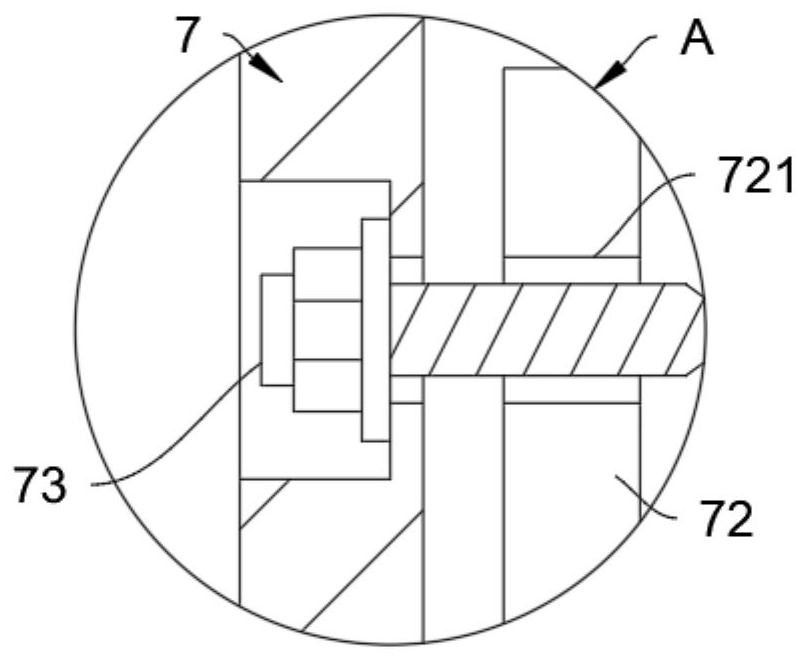

[0028] Such as Figure 1-5 As shown, a reciprocating gear processing machine with an integrated gear shaft includes a workbench 1. The workbench 1 is fixedly connected with a positioning seat 2, and the positioning seat 2 is detachably connected with a gear shaft 3. It should be noted that the positioning seat 2 One end of the pinion shaft 3 is clamped and fixed by a chuck, and the chuck adopts a common three-jaw chuck structure on the market to improve the stability of the pinion shaft 3 during processing.

[0029] The end of the gear shaft 3 away from the positioning seat 2 is provided with a clamping mechanism 4 , and the clamping mechanism 4 is movably connected with the workbench 1 through a bracket 5 .

[0030] Specifically, the clamping mechanism 4 includes a cylinder 41, a push plate 42 and a clamping block 43, the cylinder 41 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com