Navel orange brandy raw material treatment integrated device

A navel orange brandy and raw material processing technology, which is applied in the field of navel orange brandy raw material processing integrated device, can solve the problems of raw material waste of navel orange, loss outweighs gains of brewing enterprises, poor taste of navel orange brandy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

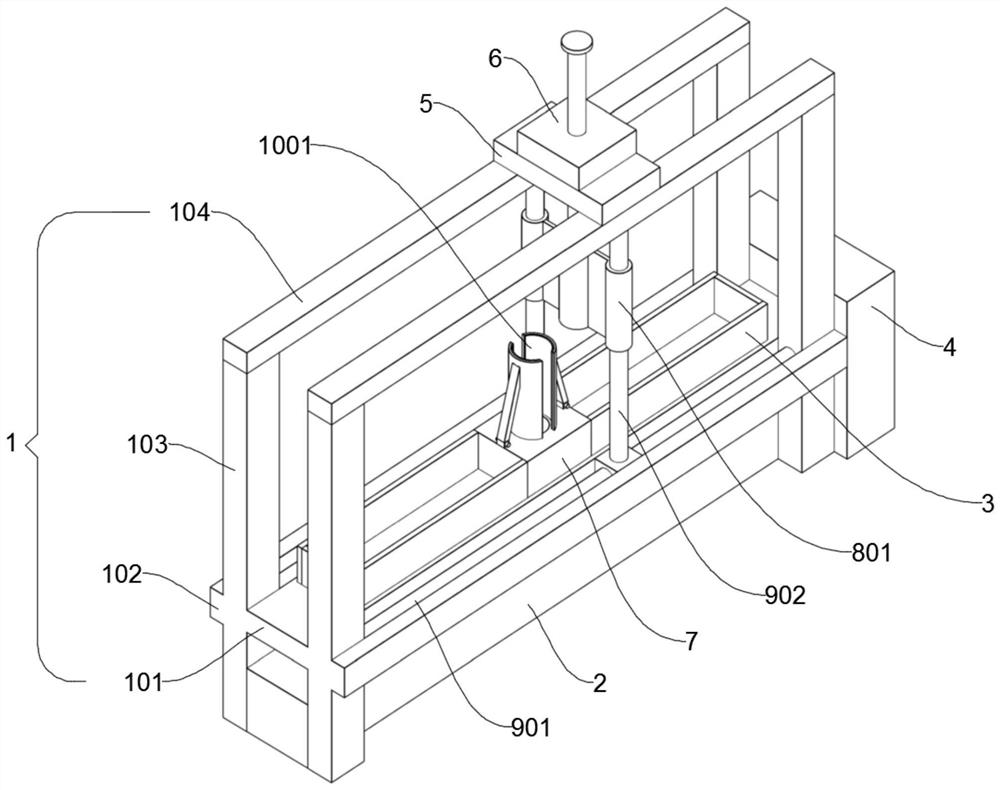

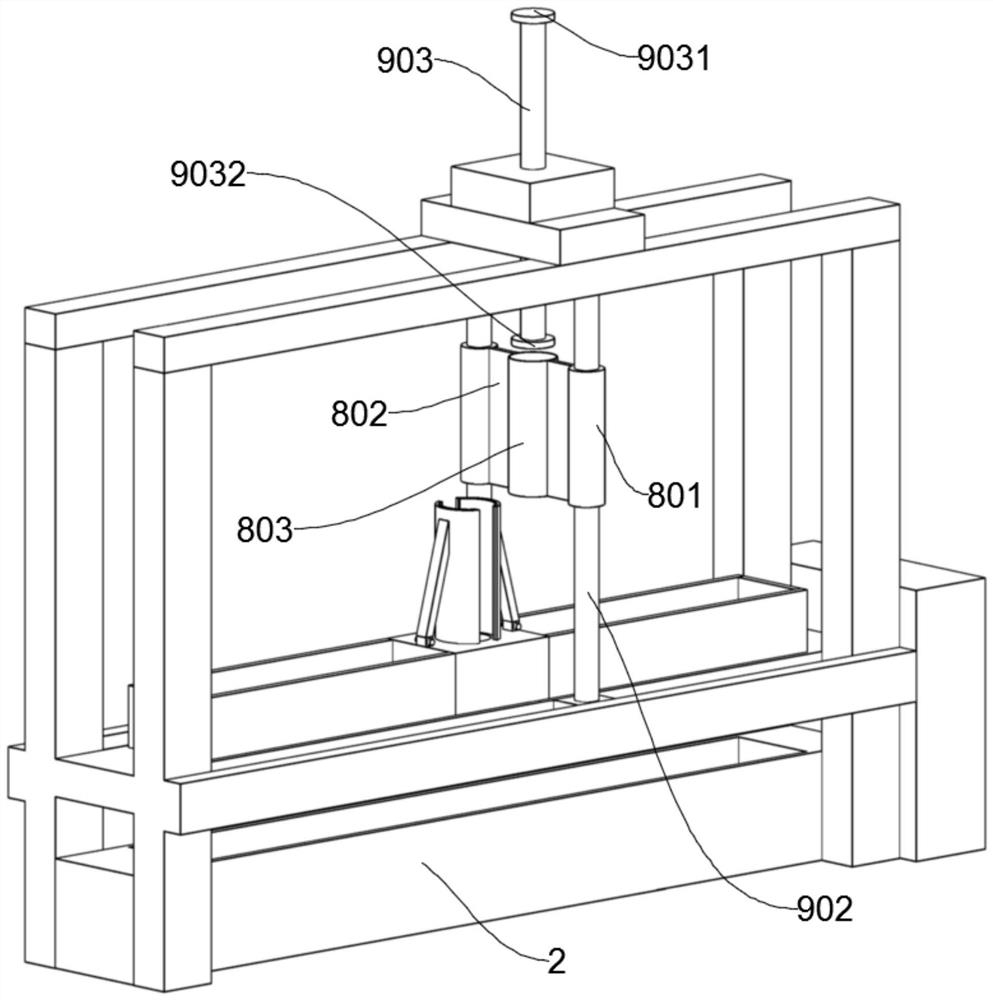

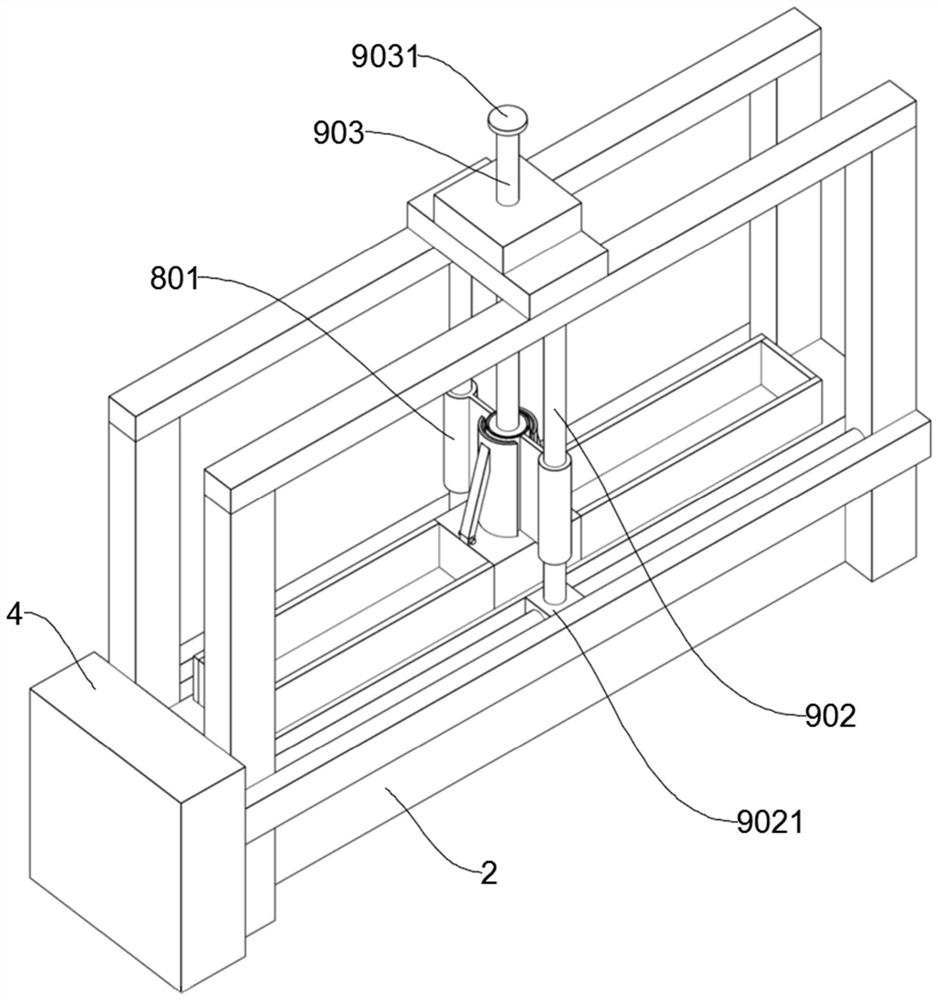

[0053] This embodiment is the structure of the navel orange brandy raw material processing integrated device, such as Figure 1 to Figure 4As shown, it includes a frame 1, a collection box 2, a leather collection box 3, a first motor box 4, a second motor box 5, a third motor box 6, a cutting table 7, a knife group 8, a drive mechanism, and a limit cylinder 10. , the collecting box 2 is placed under the frame 1, the luggage collecting box 3 is installed in the frame 1, the first motor box 4 is arranged on the side of the frame 1, and the The top surface of the frame 1 is provided with the second motor box 5 , the top surface of the second motor box 5 is connected with the third motor box 6 , and the cutting table 7 is fixed in the leather collecting box 3 , the frame 1 is provided with the knife group 8, the frame 1 is also provided with the drive mechanism, the output end of the drive mechanism is connected with the knife group 8, the cutting table 7 The limit cylinder 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com