Surface cleaning treatment process of aluminum-magnesium alloy metal frame

A metal frame, aluminum-magnesium alloy technology, used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as unclean surface cleaning, and achieve increased secondary cleaning processes and strong cleaning processes. Difficulty, improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

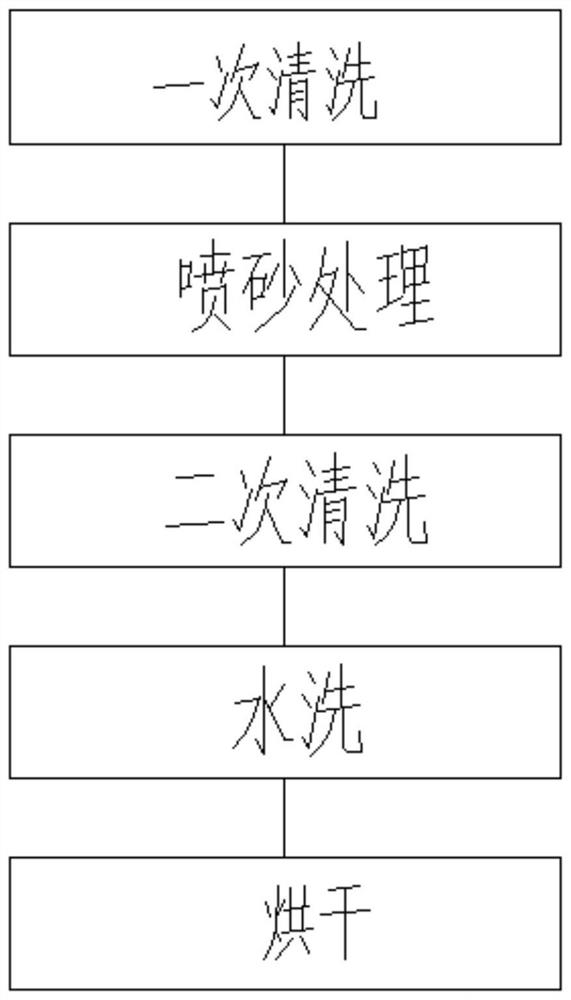

[0022] A process for cleaning the surface of an aluminum-magnesium alloy metal frame. The process for cleaning the surface of an aluminum-magnesium alloy metal frame is completed through primary cleaning, sand blasting, secondary cleaning, water washing and drying. The specific steps are as follows:

[0023] (1) One-time cleaning: immerse the aluminum-magnesium alloy metal frame in the surface cleaning solution for 20 minutes, and then pull the aluminum-magnesium alloy metal frame up and down; the surface cleaning solution consists of the following components in parts by mass: 12 parts of alcohol ether carboxylate , 22 parts of alkyl polyglucoside, 1 part of sodium carbonate, 4 parts of nitric acid, 1 part of cetylamine, 16 parts of ethylene glycol, 12 parts of quartz sand and 1400 parts of water.

[0024] (2) Sandblasting treatment: sandblasting the aluminum-magnesium alloy metal frame after one wash; the sandblasting air pressure is 0.4MPa, the sandblasting distance is 22cm, ...

Embodiment 2

[0029] A process for cleaning the surface of an aluminum-magnesium alloy metal frame. The process for cleaning the surface of an aluminum-magnesium alloy metal frame is completed through primary cleaning, sand blasting, secondary cleaning, water washing and drying. The specific steps are as follows:

[0030] (1) One-time cleaning: immerse the aluminum-magnesium alloy metal frame in the surface cleaning solution for 30 minutes, and then pull the aluminum-magnesium alloy metal frame up and down; the surface cleaning solution consists of the following components in parts by mass: 14 parts of alcohol ether carboxylate , 30 parts of alkyl polyglucoside, 2 parts of sodium carbonate, 6 parts of nitric acid, 2 parts of cetylamine, 20 parts of ethylene glycol, 14 parts of quartz sand and 1400 parts of water.

[0031] (2) Sandblasting treatment: sandblasting the aluminum-magnesium alloy metal frame after one wash; the sandblasting air pressure is 0.5MPa, the sandblasting distance is 24cm...

Embodiment 3

[0036] A process for cleaning the surface of an aluminum-magnesium alloy metal frame. The process for cleaning the surface of an aluminum-magnesium alloy metal frame is completed through primary cleaning, sand blasting, secondary cleaning, water washing and drying. The specific steps are as follows:

[0037] (1) One-time cleaning: immerse the aluminum-magnesium alloy metal frame in the surface cleaning solution for 25 minutes, and then pull the aluminum-magnesium alloy metal frame up and down; the surface cleaning solution consists of the following components in parts by mass: 13 parts of alcohol ether carboxylate , 26 parts of alkyl polyglucoside, 1.5 parts of sodium carbonate, 5 parts of nitric acid, 1.5 parts of cetylamine, 18 parts of ethylene glycol, 13 parts of quartz sand and 1400 parts of water.

[0038] (2) Sandblasting treatment: sandblasting the aluminum-magnesium alloy metal frame after one wash; the sandblasting air pressure is 0.45MPa, the sandblasting distance is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com