Micro-coagulation bead type efficient vapor permeability cloth printing and dyeing method

A micro-bead type and micro-bead technology, applied in the field of printing and dyeing, can solve the problems of poor printing and dyeing efficiency, inability to adapt to the rhythm of large-scale production, and slow dye diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

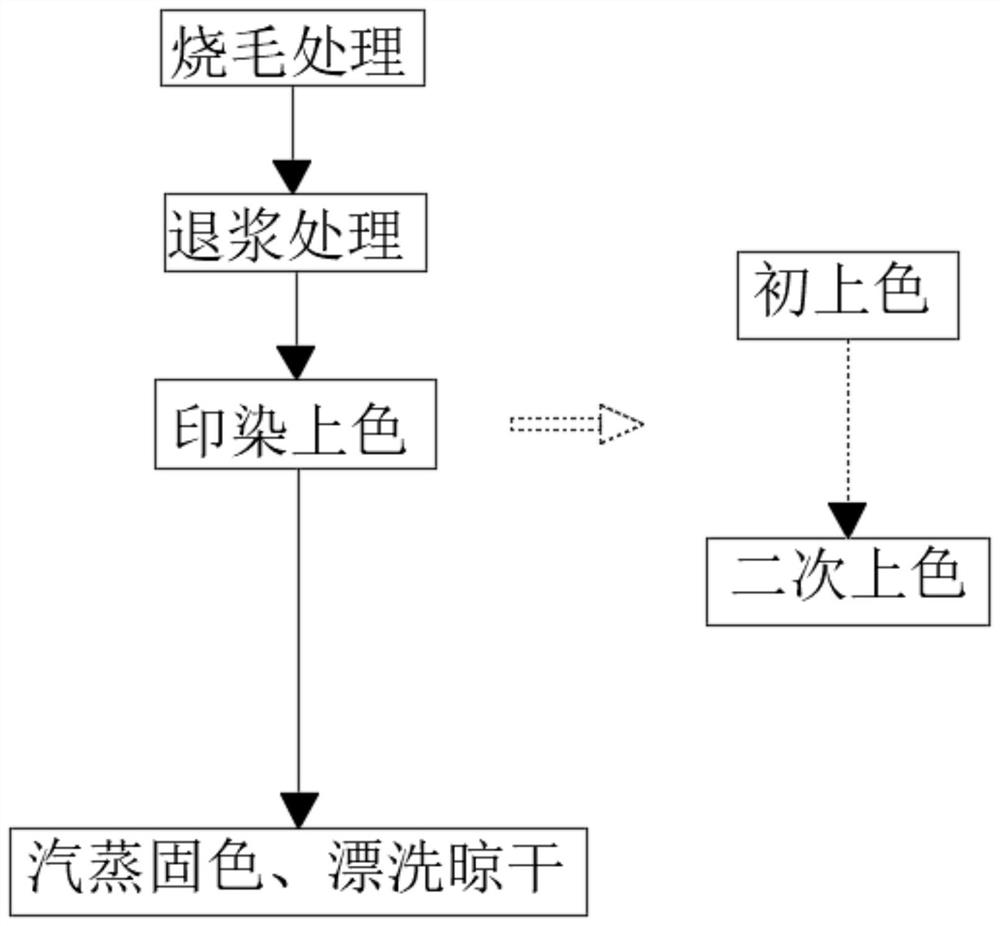

[0053] see figure 1 , a method for printing and dyeing micro-bead type high-efficiency vapor-permeable cloth, comprising the following steps:

[0054] S1. Singeing treatment: wipe the cloth over the hot metal surface to remove the fluff on the cloth surface;

[0055] S2. Desizing treatment: use a desizing machine to perform desizing treatment on the fabric;

[0056] S3. Printing and dyeing: the primary coloring of the fabric is carried out first, and then the secondary coloring is carried out through micro-condensation beads;

[0057] S31. Initial coloring: Treat and dry the cloth with refining agent, then heat the dye in the dyeing pool to above 50°C, then put the cloth into the dye, then continue to heat to 70-90°C, and maintain the Temperature, soak the cloth for 5-10 minutes, then pick up the cloth from the dye and wring it dry to get the first colored cloth;

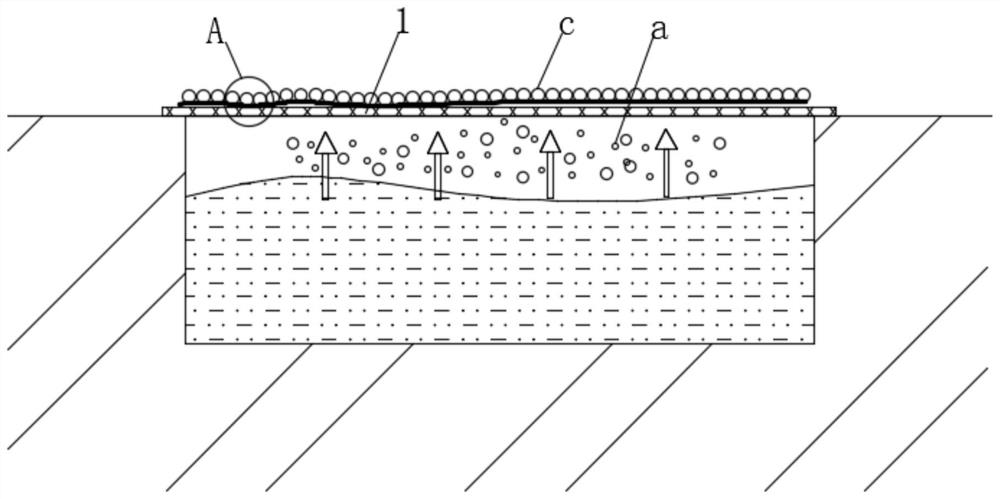

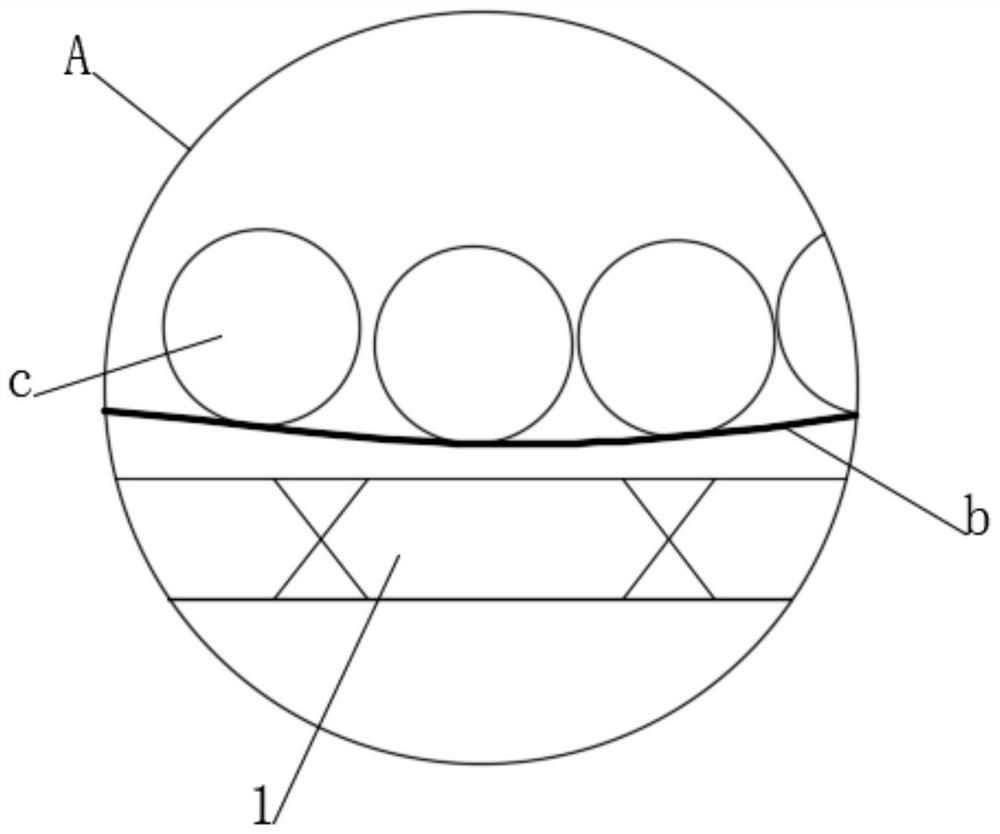

[0058] S32. Secondary coloring: Lay the first-colored fabric on the mouth of the dyeing pool, and lay microcoa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com