Flame-retardant compound cellulose acetate fiber preparation method and application

A technology of cellulose acetate and flame-retardant compounding, which is applied in the direction of artificial filaments made of cellulose derivatives, fire-resistant and flame-retardant filaments, and fiber chemical characteristics, can solve the problems of limited use of cellulose acetate, and achieve Effects of improving spinnability, reducing consumption, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

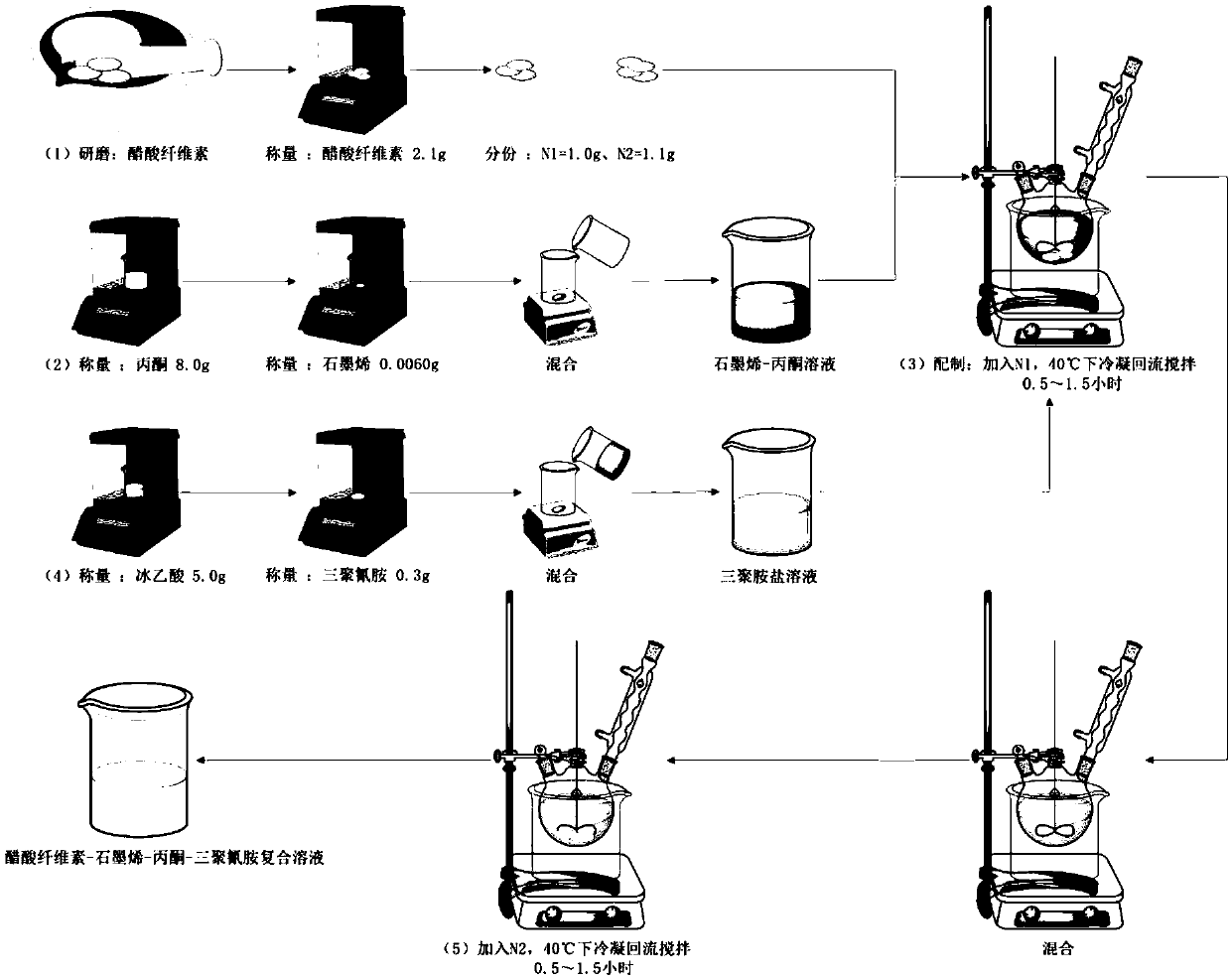

Embodiment 1

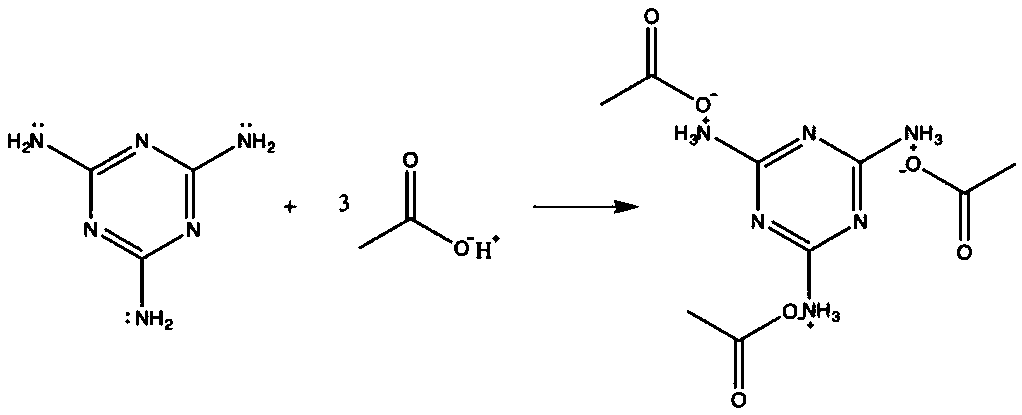

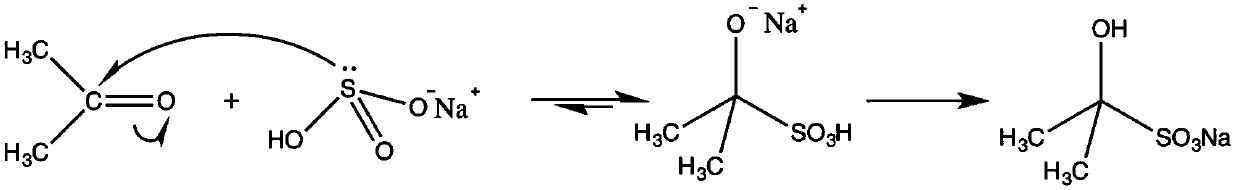

[0038] (1) Add 0.006g of graphene to 8g of acetone for dissolution, and add 1.0g of cellulose acetate powder N1. The cellulose acetate-graphene-acetone solution was condensed and refluxed at 40° C. and stirred for 0.5-1.5 hours until dissolved.

[0039] (2) The melamine of 0.1g is added in the glacial acetic acid of 2g and reacts to generate trimeric ammonium salt solution, and trimeric ammonium salt solution is joined in the cellulose acetate-graphene-acetone solution, forms cellulose acetate-graphene- Acetone-melamine complex solution. The resulting solution was condensed and refluxed at 40° C. and stirred for 0.5 hours until uniformly dispersed.

[0040] (3) Add 1.1 g of cellulose acetate powder N2 into the cellulose acetate-graphene-acetone-melamine composite solution, condense and reflux at 40° C. and stir for 0.5 to 1.5 hours until dissolved.

[0041] (4) The solution obtained in step (3) was wet-formed in a deionized water coagulation bath at 15°C, stretched 1.3 times...

Embodiment 2

[0044](1) 0.006 graphene was added to dissolve in 8 g of acetone, and 1.0 g of cellulose acetate powder N1 was added. The cellulose acetate-graphene-acetone solution was condensed and refluxed at 40° C. and stirred for 0.5-1.5 hours until dissolved.

[0045] (2) The melamine of 0.3g is added in the glacial acetic acid of 5g and reacts to generate trimeric ammonium salt solution, and trimeric ammonium salt solution is joined in cellulose acetate-graphene-acetone solution, forms cellulose acetate-graphene- Acetone-melamine complex solution. The resulting solution was condensed and refluxed at 40° C. and stirred for 0.5 hours until uniformly dispersed.

[0046] (3) Add 1.1 g of cellulose acetate powder N2 into the cellulose acetate-graphene-acetone-melamine composite solution, condense and reflux at 40° C. and stir for 0.5 to 1.5 hours until dissolved.

[0047] (4) The solution obtained in step (3) was wet-formed in a deionized water coagulation bath at 15°C, stretched 1.3 time...

Embodiment 3

[0050] (1) Add 0.0006 g of graphene to 8 g of acetone for dissolution, and add 1.0 g of cellulose acetate powder N1. The cellulose acetate-graphene-acetone solution was condensed and refluxed at 40° C. and stirred for 0.5-1.5 hours until dissolved.

[0051] (2) The melamine of 0.3g is added in the glacial acetic acid of 5g and reacts to generate trimeric ammonium salt solution, and trimeric ammonium salt solution is joined in cellulose acetate-graphene-acetone solution, forms cellulose acetate-graphene- Acetone-melamine complex solution. The resulting solution was condensed and refluxed at 40° C. and stirred for 0.5 hours until uniformly dispersed.

[0052] (3) Add 1.1 g of cellulose acetate powder N2 into the cellulose acetate-graphene-acetone-melamine composite solution, condense and reflux at 40° C. and stir for 0.5 to 1.5 hours until dissolved.

[0053] (4) The solution obtained in step (3) was wet-formed in a deionized water coagulation bath at 15°C, stretched 1.3 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com