In-hole air bag expansion pressurization and vacuum-electroosmosis composite drainage precipitation system and method

An electroosmotic dewatering and internal airbag technology, which is applied in the fields of foundation pit engineering, geological engineering and geotechnical engineering, can solve the problems of easy flow interruption, low dewatering and water output efficiency of vacuum tube wells, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

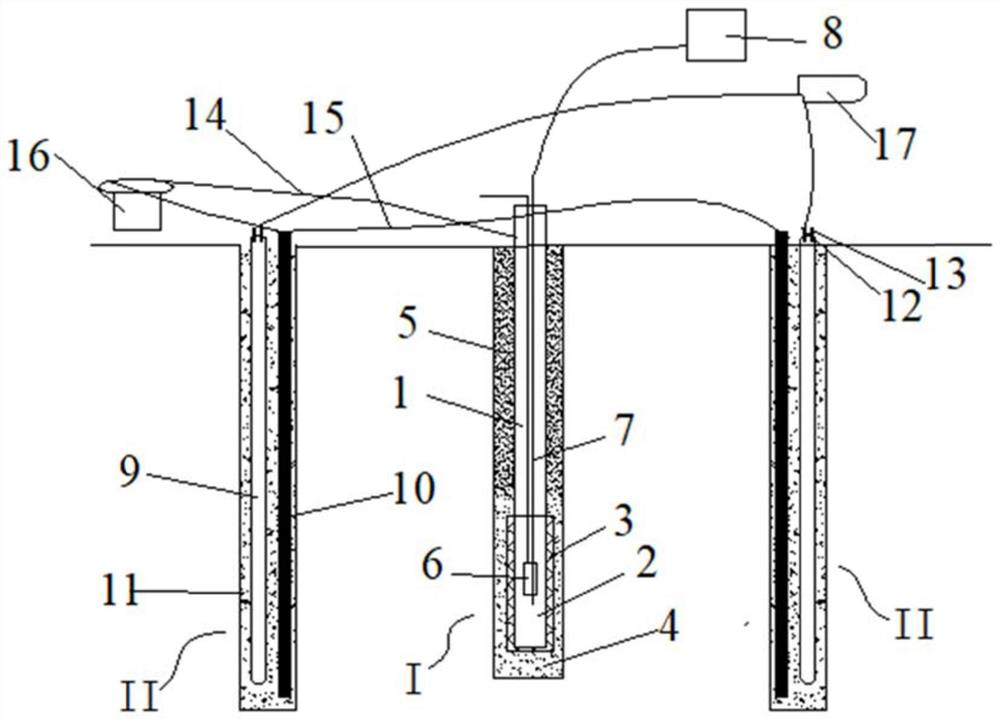

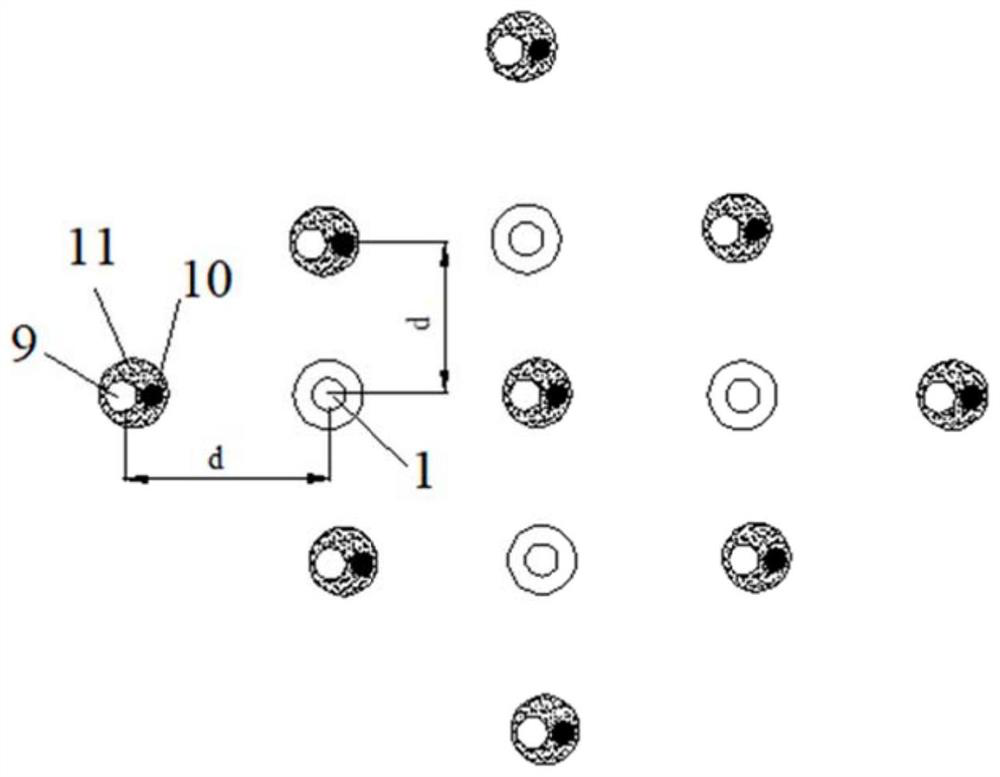

[0032] A kind of in-hole airbag expansion pressurization and vacuum-electroosmosis composite dewatering and dewatering system, such as Figure 1~2 Shown, comprise vacuum pumping mechanism 8 (preferably vacuum pump), DC power supply mechanism 16 (preferably DC generator), air compression mechanism 17 (preferably air compressor), a plurality of vacuum wells 1 and distribute in each Multiple lateral pressurization holes II around the vacuum dewatering well I;

[0033] The well tube of vacuum dehydration well 1 is connected with the negative electrode of DC power supply mechanism 16 by cathode connection electric wire 14, is provided with pumping mechanism and the vacuum exhaust pipe 7 that is connected with vacuum mechanism 8 in the well tube;

[0034] An anode metal post 10 and a flexible air bag 9 are placed in the lateral pressurization hole II, and the outside of the flexible air bag 9 and the anode metal post 10 is filled with a hole-filling mud 11, and the anode metal post ...

Embodiment 2

[0039] A kind of airbag expansion and pressurization and vacuum-electroosmosis compound dewatering dewatering method in a hole adopts the system of embodiment 1, the method includes vacuum tube well dewatering and vacuum intermittent electroosmotic dewatering successively, vacuum intermittent electroosmotic dewatering adopts continuous For vacuum tube well dewatering and intermittent electroosmotic dewatering, vacuum lateral pressurization dewatering is carried out in the interval of electroosmotic dewatering. Vacuum lateral pressurization dewatering refers to horizontal pressurization while vacuum tube well dewatering;

[0040] Vacuum well point dewatering is carried out by vacuum dewatering well I, which is used to discharge most of the free water under the action of vacuum suction to save electroosmotic dewatering time;

[0041]Vacuum intermittent electroosmotic dewatering is carried out by vacuum tube well dewatering by using vacuum dewatering well I, and using DC power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com