Fluff anti-seepage type concrete slab for building external wall

A technology for concrete slabs and building exterior walls, applied in buildings, building components, building structures, etc., can solve problems such as poor impermeability, passive anti-seepage methods, and performance degradation, so as to reduce contact, improve anti-seepage performance, Promotes a quick-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

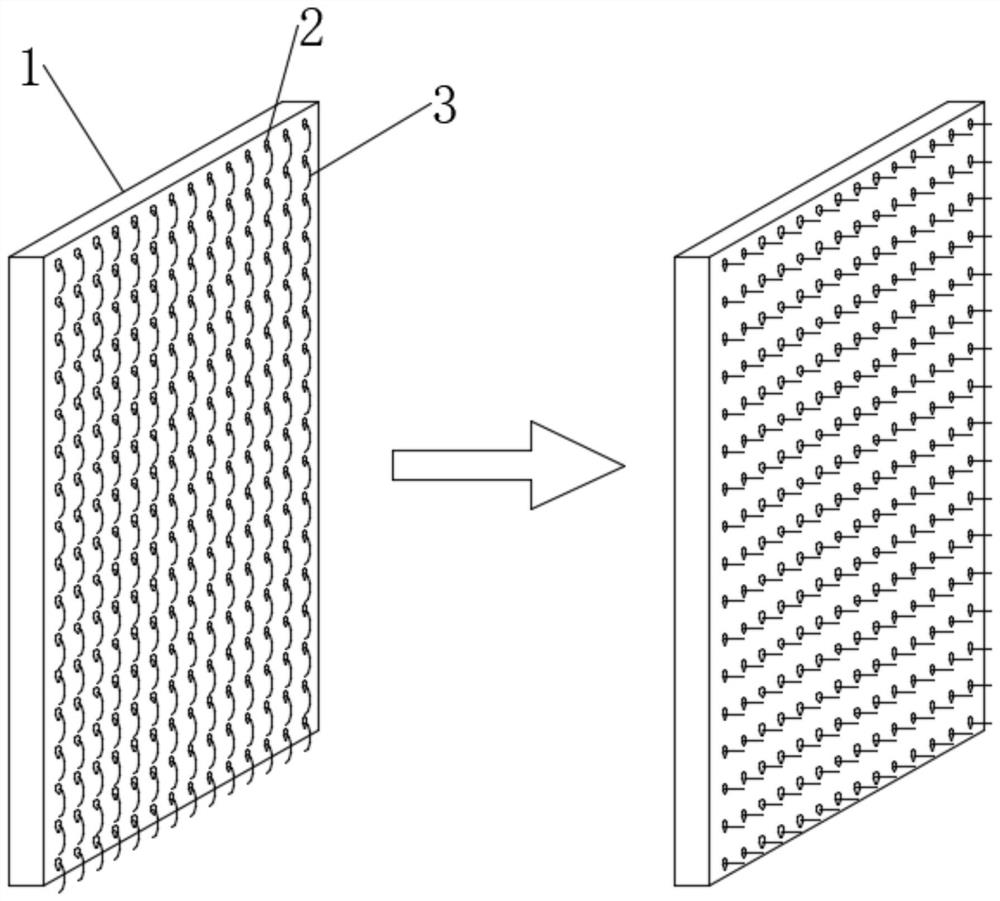

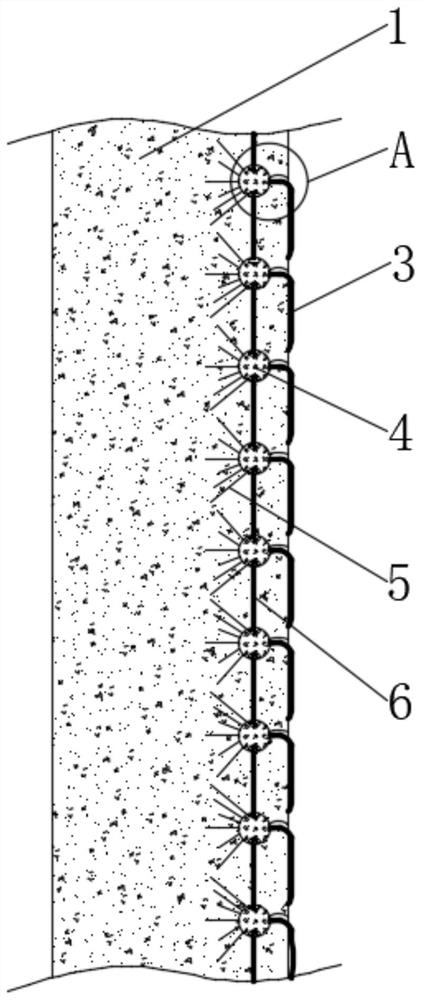

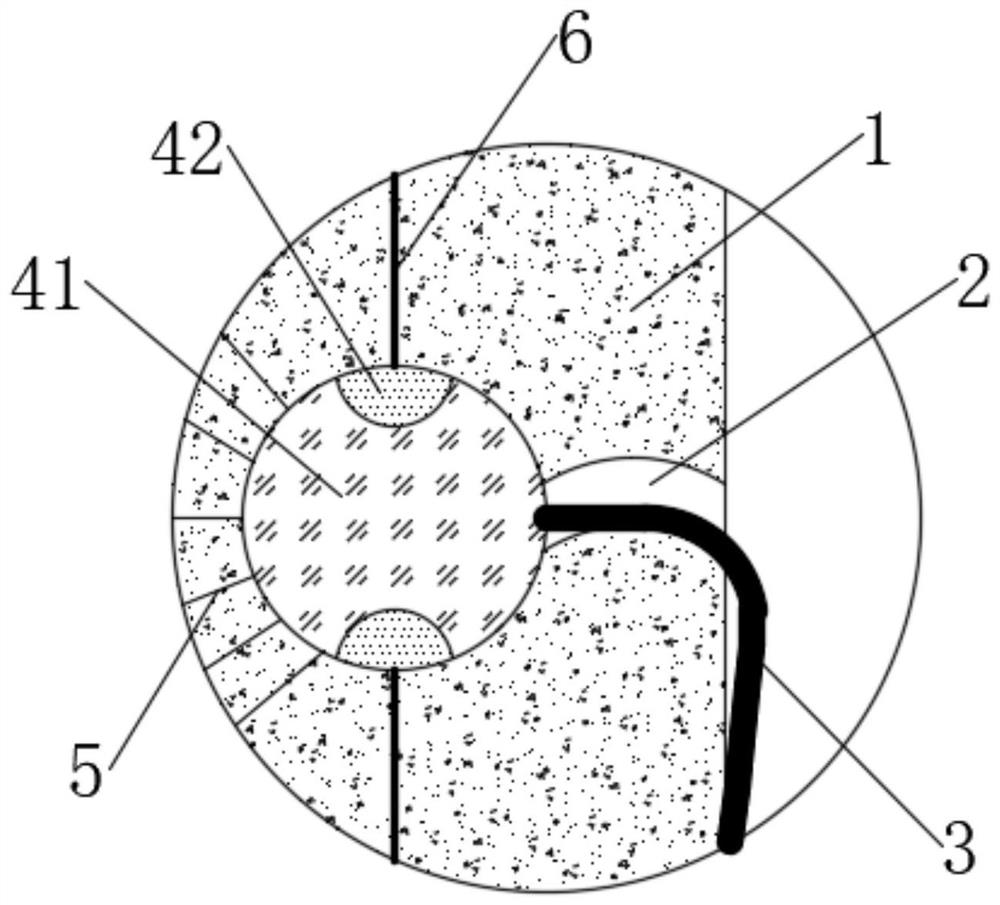

[0043] see Figure 1-2 , a kind of fluff-type anti-seepage concrete slab for building exterior walls, comprising a concrete slab body 1, the concrete slab body 1 is prefabricated by impervious concrete, and the impermeable concrete refers to concrete whose impermeability level is equal to or greater than P6 level. The compactness of the concrete improves the pore structure, thereby reducing the permeation channels and improving the impermeability. The inner surface of the concrete slab body 1 is inlaid and connected with a plurality of evenly distributed self-releasing and storing water spheres 4, and between the self-releasing and storing water spheres 4 Connected with a network of water-absorbing wires 6, the outer surface of the concrete slab body 1 is provided with a plurality of drainage pores 2 corresponding to the self-releasing and storing water polo 4, and the drainage pores 2 are connected with the self-releasing and storing water polo 4, and the drainage pores 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com