Drill rod assembly and drilling machine with same

A technology of drill pipe components and drill pipes, which is applied in the direction of drill pipes, drilling equipment and methods, drill bits, etc., and can solve the problems of large number of uses, high construction costs, and low construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

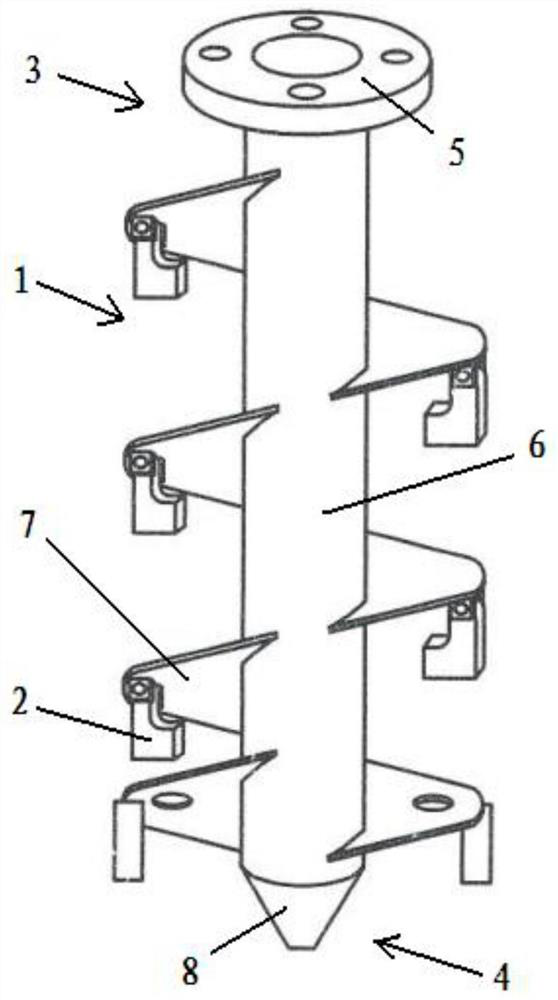

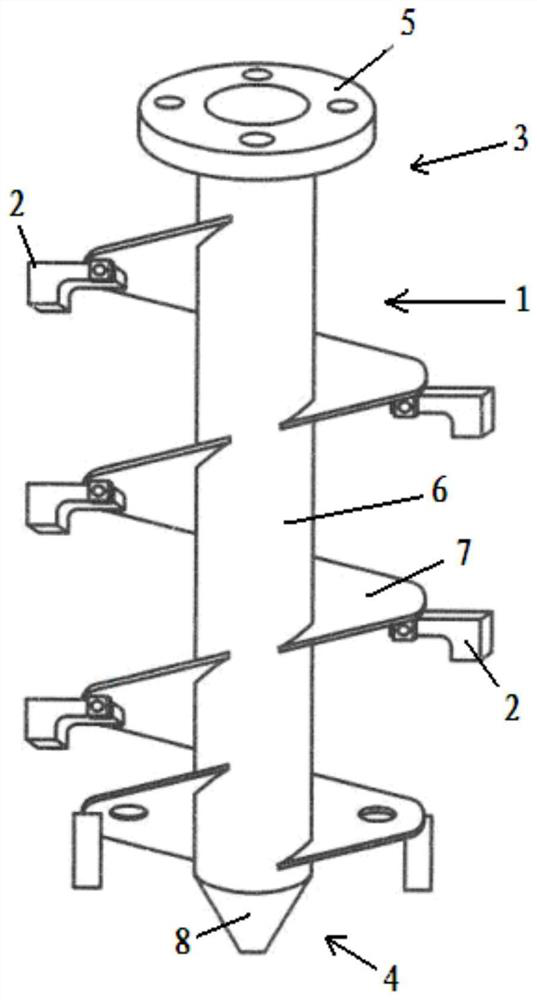

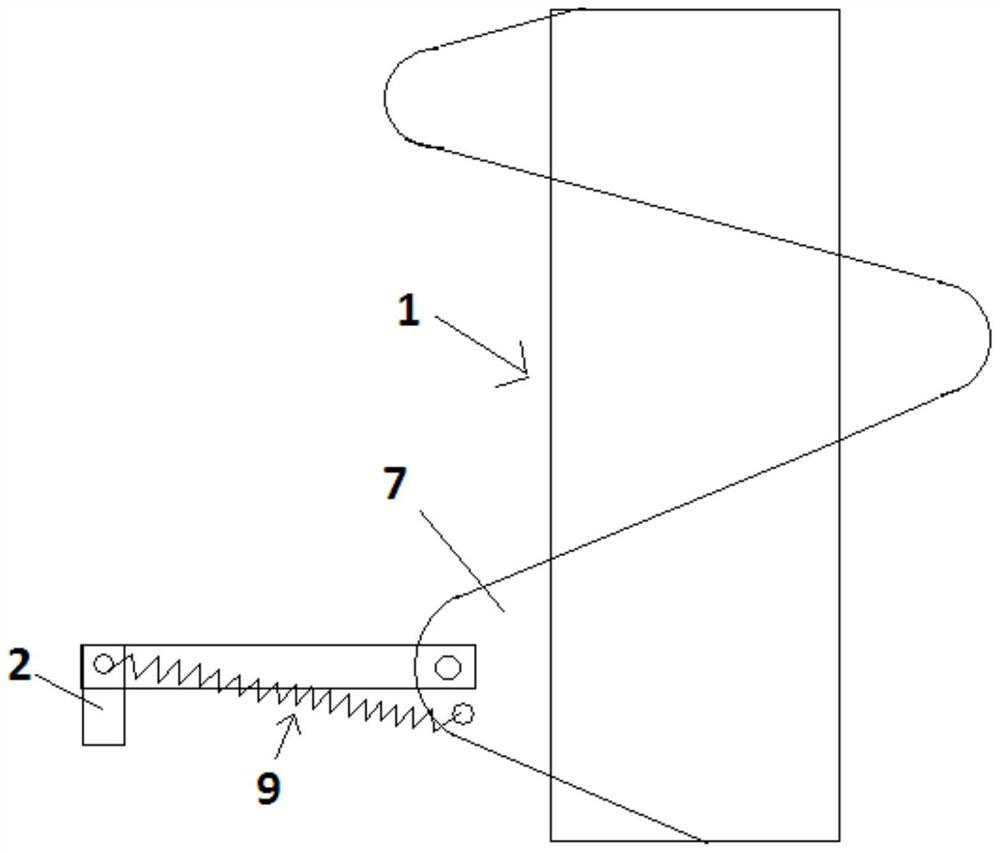

[0040] Such as figure 1 As shown, a drill pipe assembly includes: a drill pipe part 1; wherein, it also includes a cutting part 2, which can be flexibly connected to the drill pipe part 1 in a radially expandable manner, and is suitable for cooperating with the drill pipe part Boring is achieved, wherein the drill stem member has a drill diameter that is greater in the deployed state of the cutting member than in the undeployed state. Preferably, the drill pipe part has a power end 3, and a drilling end 4 opposite to the power end 3; as figure 2 As shown, the direction in which the cutting member 2 is radially deployed is from the drilling end 4 to the power end 3. Optionally, the cutting part 2 is hinged on the drill rod part 1 . The power end 3 of the drill rod assembly may also be provided with a connection structure for connecting with an external device, such as a flange structure 5. As a further improvement method, such as figure 1 As shown, the drill pipe component...

Embodiment 2

[0045] Such as Figure 4 As shown, this embodiment provides a drilling machine, including: a frame 11; wherein, also includes: a casing assembly 12, installed on the frame 11, including a casing 13 for protecting the hole wall; and the above The drill rod assembly 14 introduced in Embodiment 1, the drill rod assembly 14 is installed on the frame 11, at least partly movably embedded in the casing 13; the drill rod power part 28 is connected with the drill rod part , to provide power for the rotation of the drill rod component, preferably, the drill rod power component can be connected to the power end of the drill rod component, more preferably, can be detachably connected to the power end; the drilling rig It also includes a driving mechanism 15, which is installed on the frame 11 and connected with the casing assembly 12 and the drill pipe assembly 14 respectively, so as to realize the up and down movement of the casing assembly 12 and the drill pipe assembly 14 respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com