Combined fishing tool and fishing method for inclined chopping bit in deepwater karst environment

A percussion drill and drill bit technology, which is applied in the direction of earthwork drilling, wellbore/well parts, etc., can solve the problems of easy delay in construction period, drill bit sticking, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

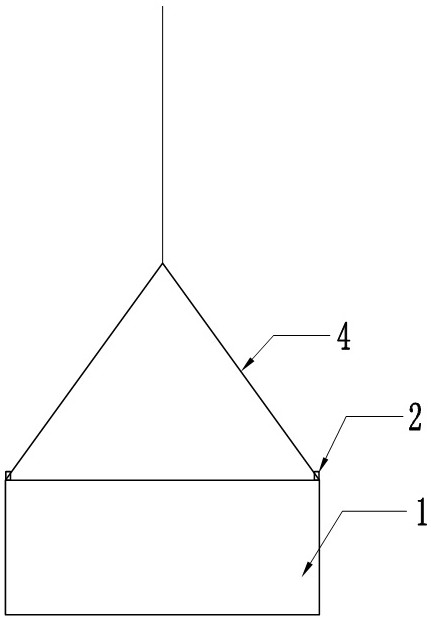

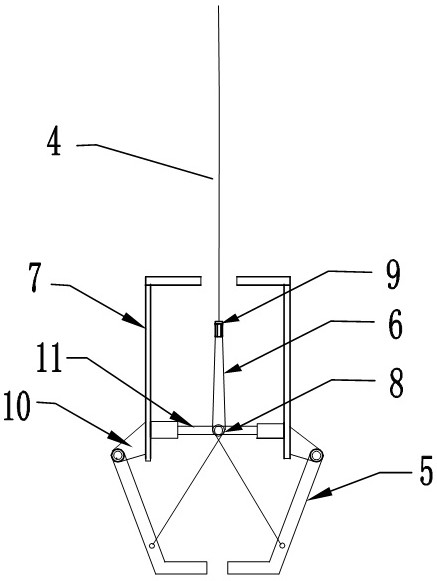

[0025] A combined salvage tool for inclined percussion drill bits in deep-water karst geological environment, characterized in that it consists of a hollow hammer and a bit grab, wherein:

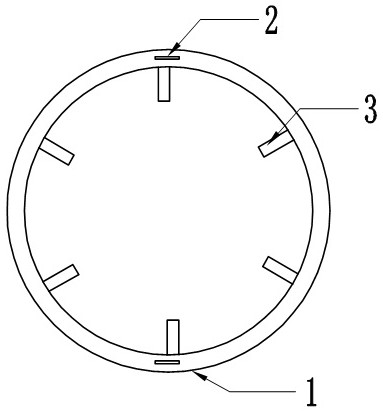

[0026] The hollow hammer is a ring-shaped steel structure, which is composed of a ring body 1, a lifting lug 2, and a stiffened steel plate 3. The diameter of the ring body 1 is the same as the outer diameter of the dropped impact drill bit. Two lifting lugs 2 are symmetrically fixed on the top of the ring body 1, and several stiffened steel plates 3 for strengthening the rigidity of the ring body 1 are evenly fixed on the inner wall of the ring body 1;

[0027] The drill bit grab consists of a grab shell 7, a jaw plate 5, a steel wire rope 6 inside the grab, and a fixed pulley 8. At the bottom of the cylindrical grab shell 7, there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com