Method for predicting residual service life of rolling bearing based on EEMD-MCNN-GRU

A technology for rolling bearings and life prediction, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., and can solve the problems of weak prediction model robustness, low prediction accuracy, and incomplete feature extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

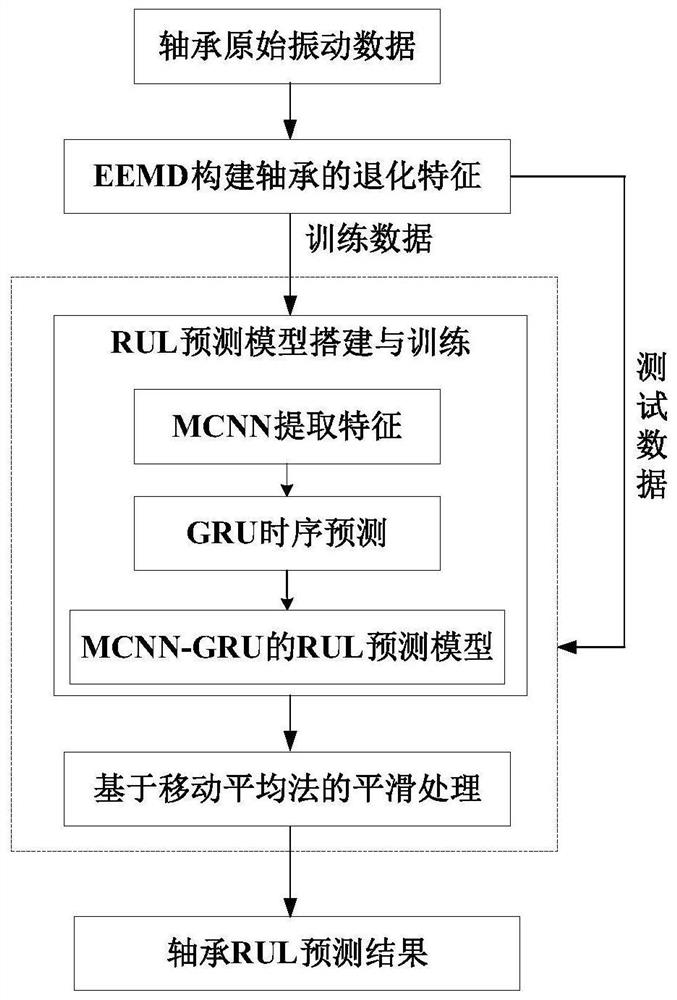

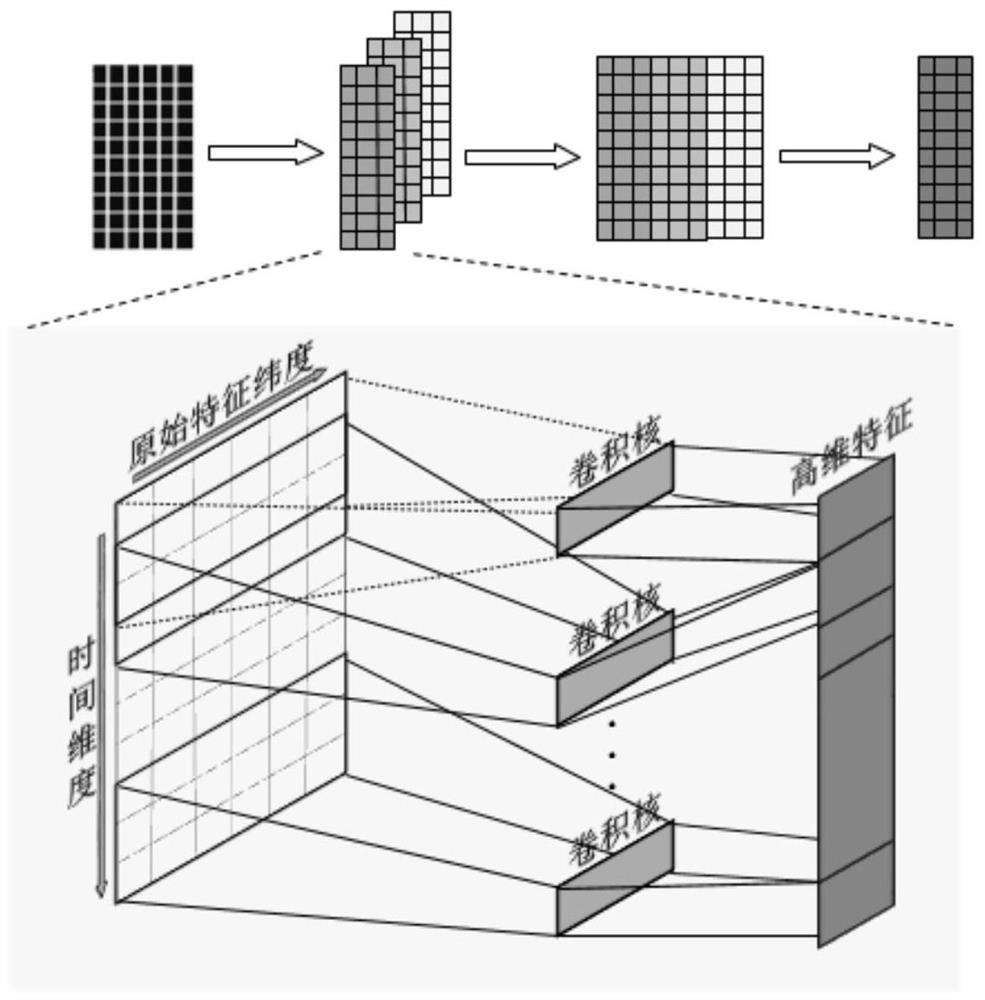

[0087] The specific flowchart of the embodiment of the method for predicting the remaining service life of rolling bearings based on EEMD-MCNN-GRU proposed by the present invention is as attached figure 2 As shown, including the following steps:

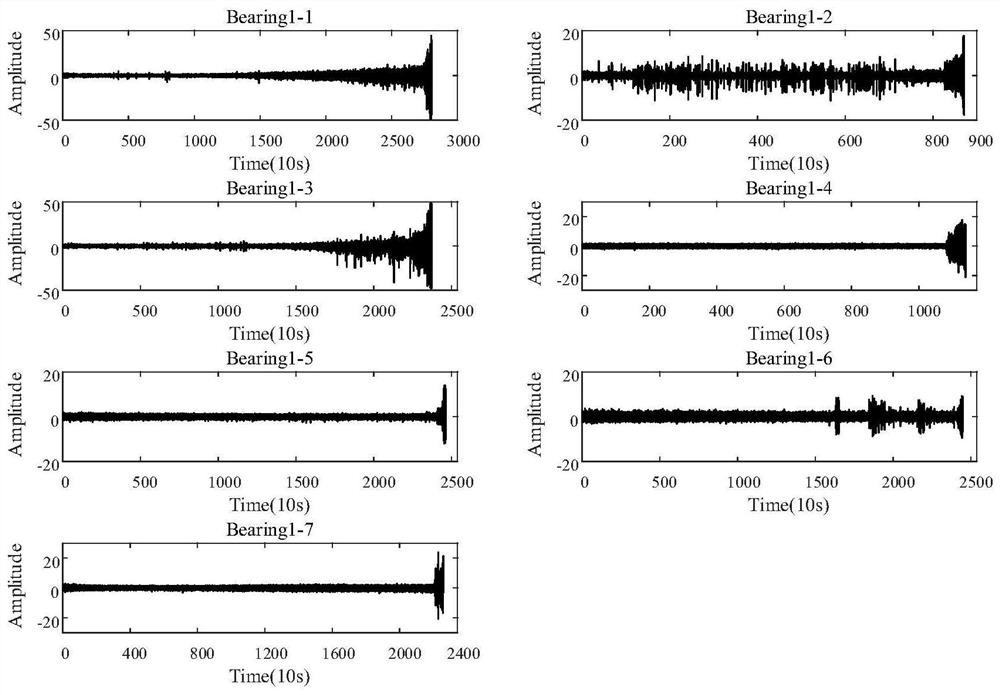

[0088] S1: EEMD-based rolling bearing degradation characteristic data set construction

[0089] Collect the full life cycle vibration data of 7 rolling bearings from the beginning of use to failure, and then use EEMD to decompose the original vibration data into multiple IMF components of different frequency bands with limited bandwidth according to their sampling period, as expressed in equation (1) , Which greatly reduces the impact of data fluctuations caused by modal aliasing on the prediction performance of the algorithm. Construct the degradation characteristics of bearing vibration signals on different time s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com