Charge pump circuit, chip and electronic equipment

A charge pump and circuit technology, applied in the field of circuits, can solve the problems of the chip cannot meet the requirements of the application side, the duration is short, and the performance of electronic equipment is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

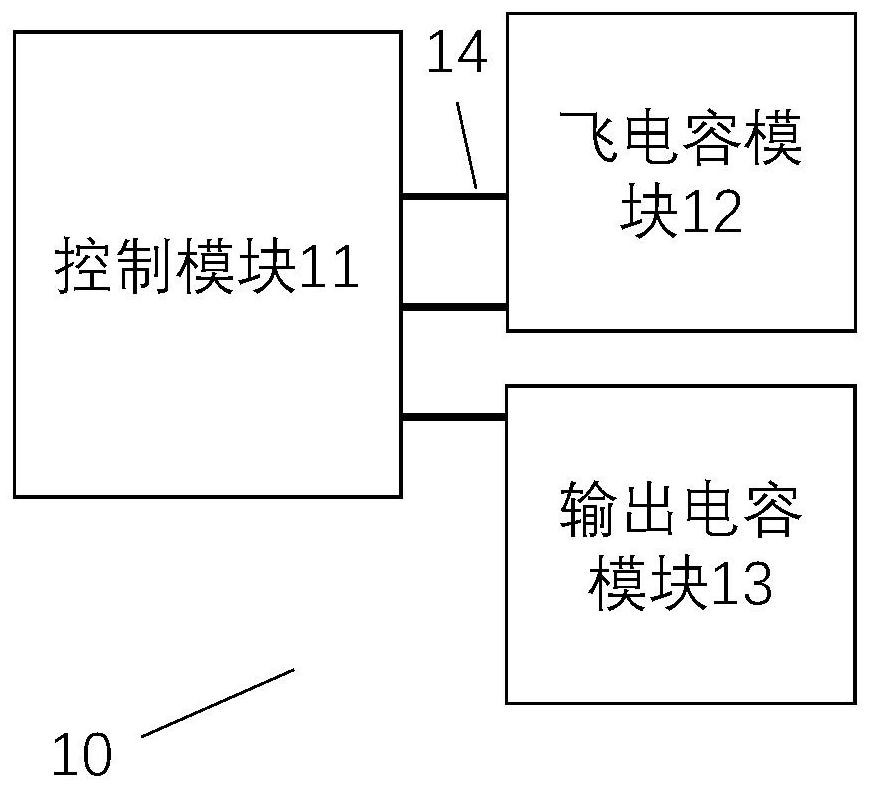

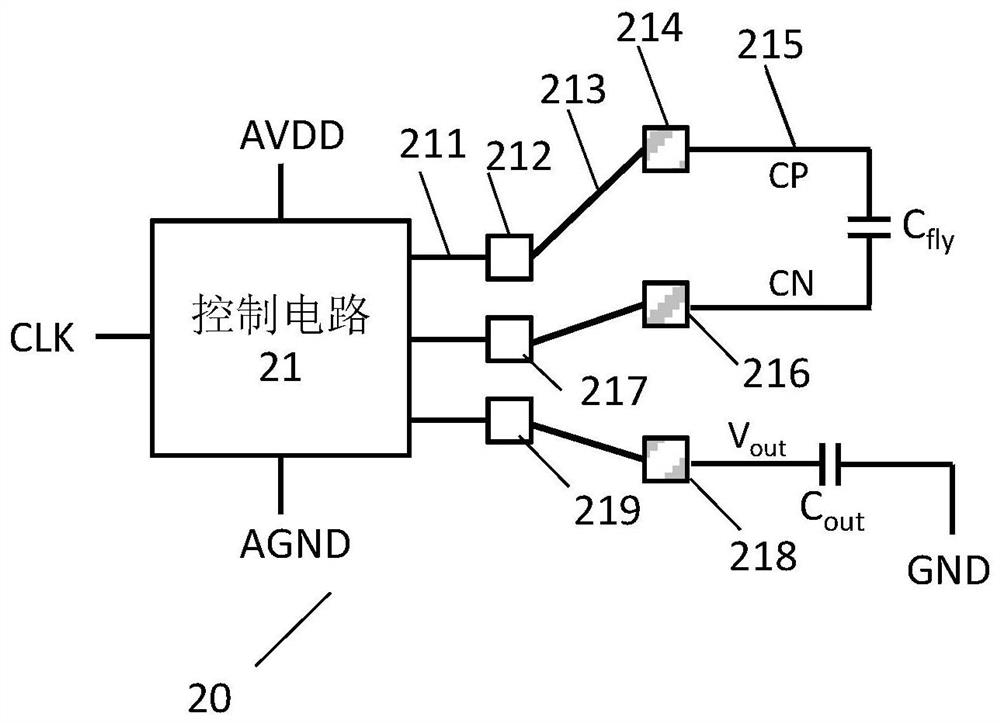

[0050] The technical solution in this application will be described below with reference to the accompanying drawings.

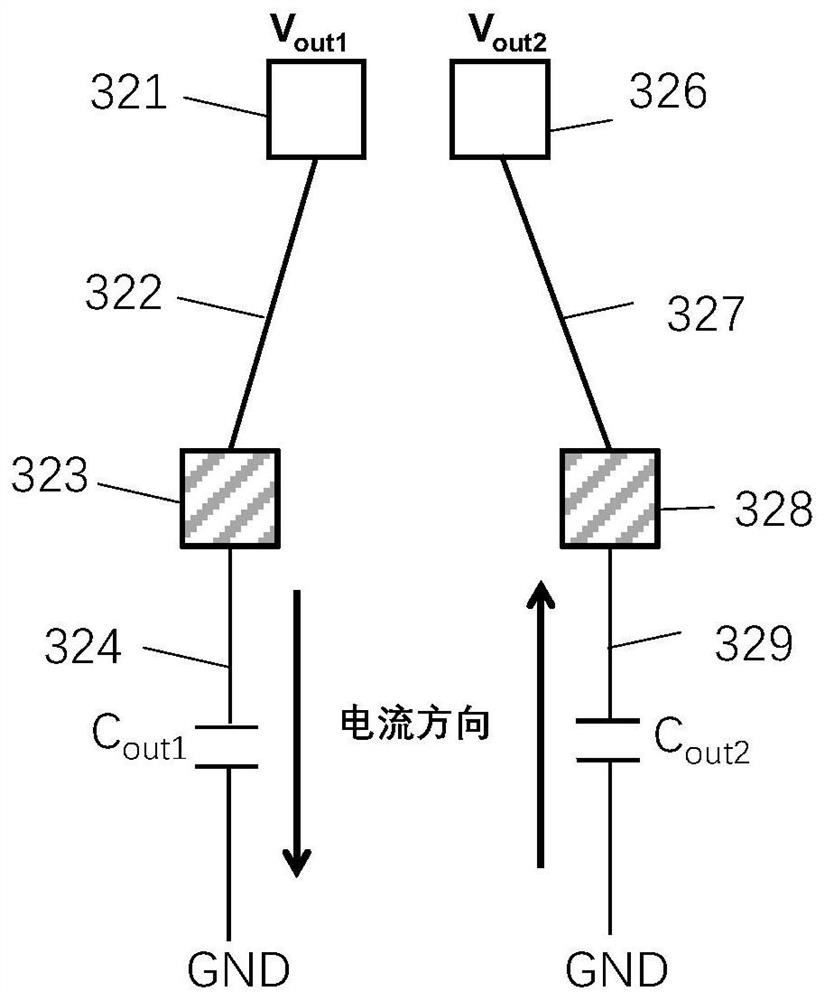

[0051]The flying capacitor Cfly and the output capacitor Cout in the charge pump circuit are periodically charged and discharged to obtain a stable boosted or bucked output voltage Vout. According to the working principle of the charge pump circuit, the two ends of the flying capacitor Cfly are generally divided into CP and CN. The CP is the end connected to the positive plate of the flying capacitor, and the CN is the end connected to the negative plate of the flying capacitor. In the charging state, the current flows from the CP terminal through the flying capacitor Cfly to the CN terminal. When the flying capacitor Cfly is in the discharging state, that is, when the flying capacitor Cfly charges the output capacitor Cout, the current flows from the CN terminal through the flying capacitor Cfly to the CP terminal. The non-ground terminal of the output capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com