New welding process method for connecting joints between branch pipe and main pipe of steel structure in ocean engineering

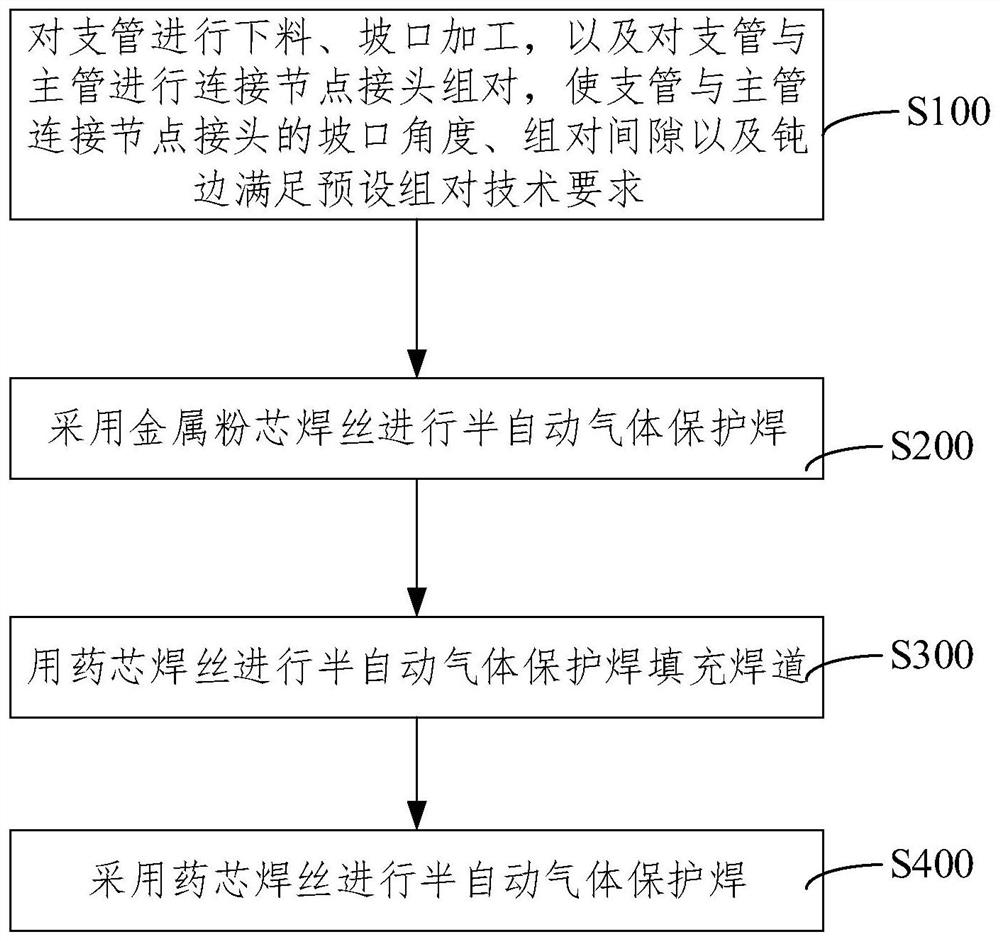

A technology for connecting nodes and welding processes, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of high labor intensity and low welding efficiency, and achieve the effect of reducing labor intensity, improving welding efficiency and reducing welding cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] The joint angle between the branch pipe of the offshore engineering steel structure and the main pipe to be welded is 50°, the maximum dihedral angle of this node is 130°, and the minimum dihedral angle is 50°, involving three areas B, C, and D . In this case, the saddle mouth CNC cutting machine is used to blank and groove the branch pipe steel pipe, so that each area of the joint (position B, C, D) meets the technical requirements of the preset group as follows:

[0106] Area B: When the dihedral angle of the connecting node between the branch pipe and the main pipe is greater than or equal to 90° and less than 130°, the bevel angle of the joint joint between the branch pipe and the main pipe is 45°, and the gap between the joints is 2 mm to 6 mm , the blunt edge is 0mm~2mm;

[0107] Area C: When the dihedral angle of the connecting node between the branch pipe and the main pipe is greater than or equal to 75° and less than 90°, the bevel angle of the joint between...

Embodiment 2

[0138] The branch angle of the joint between the branch pipe of the offshore engineering steel structure and the main pipe to be welded is 35°, the maximum dihedral angle of the joint is 145°, and the minimum dihedral angle is 35°, involving A, B, C, D, E, F three areas. . In this case, the saddle mouth CNC cutting machine is used to blank and groove the branch pipe steel pipe, so that each area of the joint (position B, C, D) meets the technical requirements of the preset group as follows:

[0139] Area A: When the dihedral angle of the connecting node between the branch pipe and the main pipe is greater than or equal to 135° and less than 145°, the bevel angle of the joint joint between the branch pipe and the main pipe is 45°, and the gap between the joints is 2 mm to 6 mm , no blunt edge requirement;

[0140] Area B: When the dihedral angle of the connecting node between the branch pipe and the main pipe is greater than or equal to 90° and less than 135°, the bevel ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com