A production method of anti-skid and anti-corrosion pre-buried channel

A technology of pre-embedded channel and production method, applied in metal rolling and other directions, can solve the problems of low yield strength, unattainable, and small axial anti-slip force of ordinary stainless steel, and achieves elimination of heat-affected zone residues and improved use safety. , the effect of channel bearing capacity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

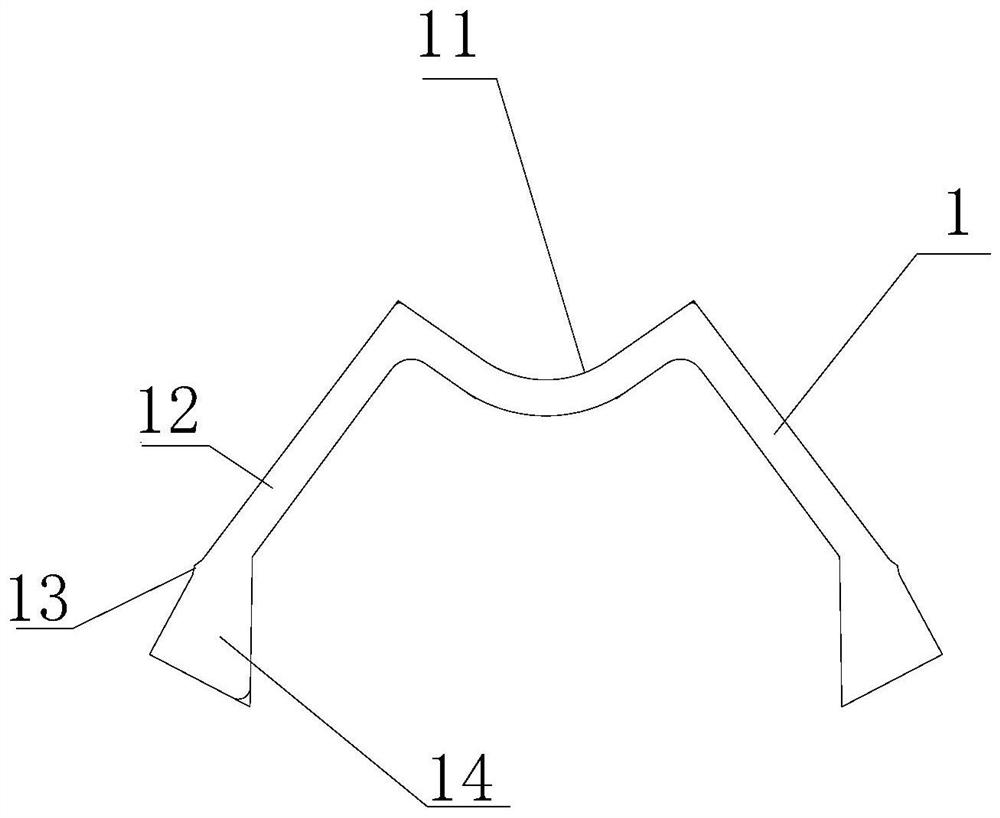

[0072] In this embodiment, a stainless steel rectangular billet with a cross-sectional size of 120 mm×120 mm is used as a raw material to produce a straight dovetail double-tooth anti-slip and corrosion-resistant channel. The cross-section of the anti-slip tooth groove is rectangular, the width is 30mm, and the height is 26mm. The anchor leg is a "king"-shaped anchor leg. The material of the anti-slip tooth groove and the anchor leg is 316L stainless steel, and the assembly method is thermal anchoring.

[0073] (1) After heating the stainless steel rectangular billet to 1200°, that is, the rolling temperature, it passes through a φ520 continuous rolling mill and is rolled 13 times to make a long-leg channel steel 1 with a leg length of 34mm and a waist width of 30mm (such as Figure 1a As shown), the top of the long-leg groove leg 1 is rolled with a dovetail platform 14, and the outer side of the joint between the dovetail platform 14 and the groove leg 12 is provided with an ap...

Embodiment 2

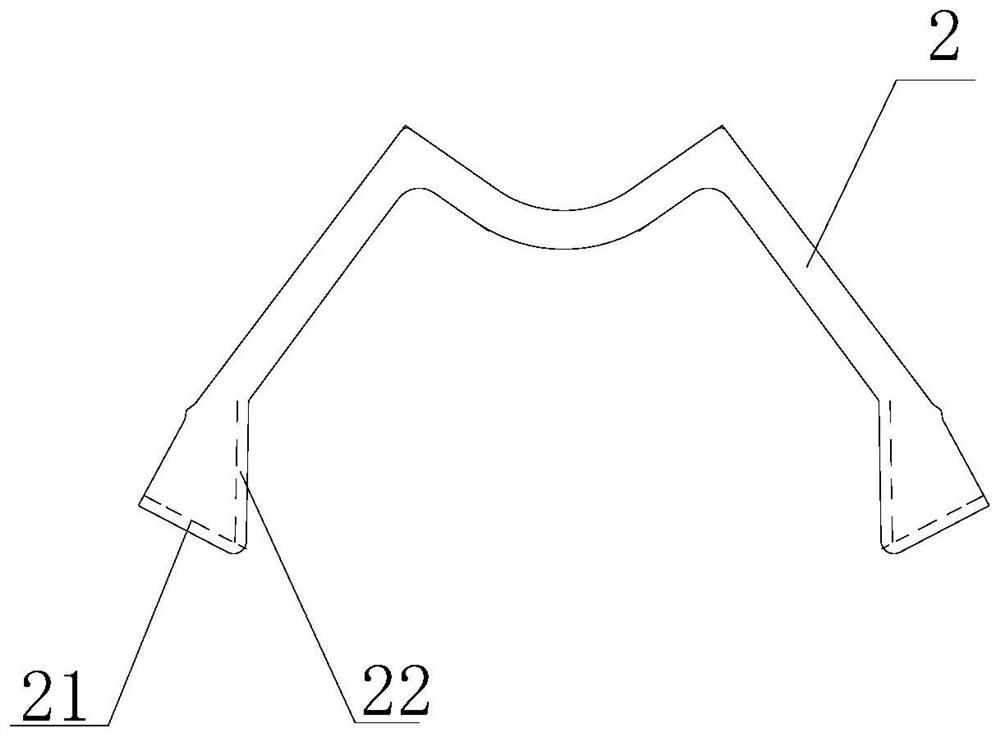

[0080] In this embodiment, a φ100mm×100mm low-alloy steel round billet is used as a raw material to produce an arc-shaped flat-tooth single-tooth anti-slip and corrosion-resistant channel. The cross-section of the anti-slip tooth groove is V-shaped, the width is 41mm, and the height is 28mm. The anchor leg is a "T"-shaped anchor leg. The material of the anti-skid tooth groove and the anchor leg is Q355B, and the assembly method is welding.

[0081] (1) The low-alloy steel round billet is heated to 1150°, which is the rolling temperature, and then rolled. After 11 times of rolling through a φ520 continuous rolling mill, a long-leg channel steel with a leg length of 37mm and a waist width of 41mm is produced. A platform is rolled out of the top of the long-leg slot leg, and a top angle is provided on the outer side of the junction between the platform and the slot leg; the middle part of the slot waist is provided with a concave arc with a central angle of 120°-170°. The rolled ...

Embodiment 3

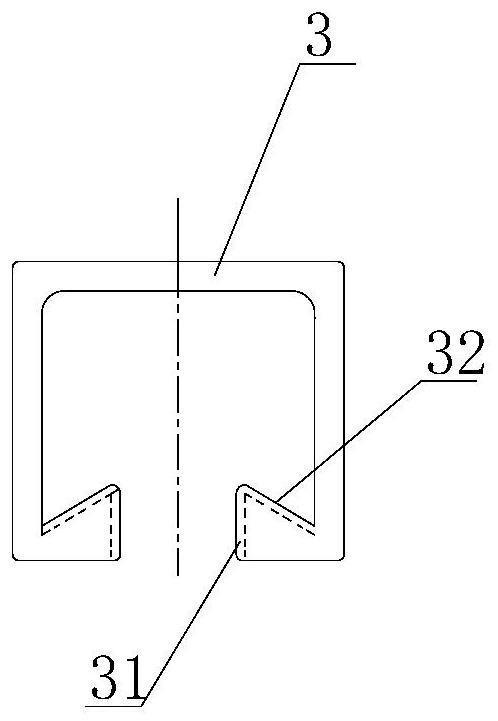

[0090] In this embodiment, a low-alloy steel billet with a cross-sectional size of 150mm×150mm is used as a raw material to produce a straight flat-tooth single-tooth anti-slip and corrosion-resistant channel. The cross-section of the anti-slip tooth groove is U-shaped, with a width of 41mm and a height of 41mm. The anchor leg is an "I"-shaped anchor leg. The material of the anti-slip tooth groove and anchor leg is 08CrNi, and the assembly method is anchored.

[0091] (1) The low-alloy steel billet is heated to 1180°, that is, the rolling temperature, and then rolled. After 15 times of rolling through a φ520 continuous rolling mill, a long-leg channel steel with a leg length of 50 mm and a waist width of 41 mm is produced. There is a top angle on the outside of the leg end 9mm; the waist is flat. The rolled long-leg channel steel is put into storage after cooling, straightening and sawing;

[0092] (2) Profiling flame cutting is adopted, and the teeth are processed at the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com