Intelligent linkage control manner for production line of extrusion molding equipment

A production line, intelligent technology, applied in the direction of coating, etc., can solve the problems of low automation cost, low overall production efficiency, quality out of control, etc., to achieve the effect of improving the degree of automation, improving product quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention and does not constitute a limitation to the protection scope of the present invention.

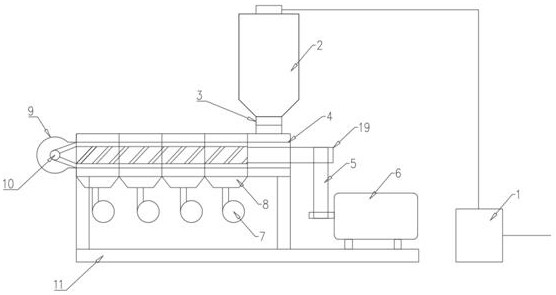

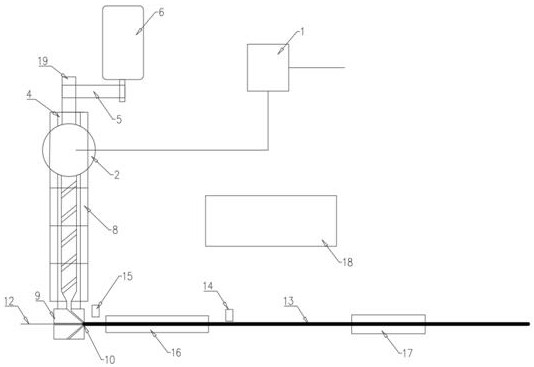

[0027] like Figure 1-2 As shown, an intelligent linkage control method for a production line of extrusion equipment includes the following steps:

[0028] 1) The production line operator pre-sets the production line operation time, and the production line control system 18 is in the standby state. When the predetermined time is reached, the production line control system automatically starts to control the extruder according to the process setting parameters and performs heating and temperature control, automatic detection The weight of PE plastic particles in the hopper automatically controls the addition of PE plastic particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com