Film blowing machine for plastic film

A plastic film and film blowing machine technology, which is applied in the field of plastic film blowing machines, can solve problems such as unsatisfactory cooling effect, easy scratching of the outer wall of the plastic film on the herringbone board, and difficulty in guaranteeing the processing quality, so as to achieve small deformation and prevent Overstretch, prevent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

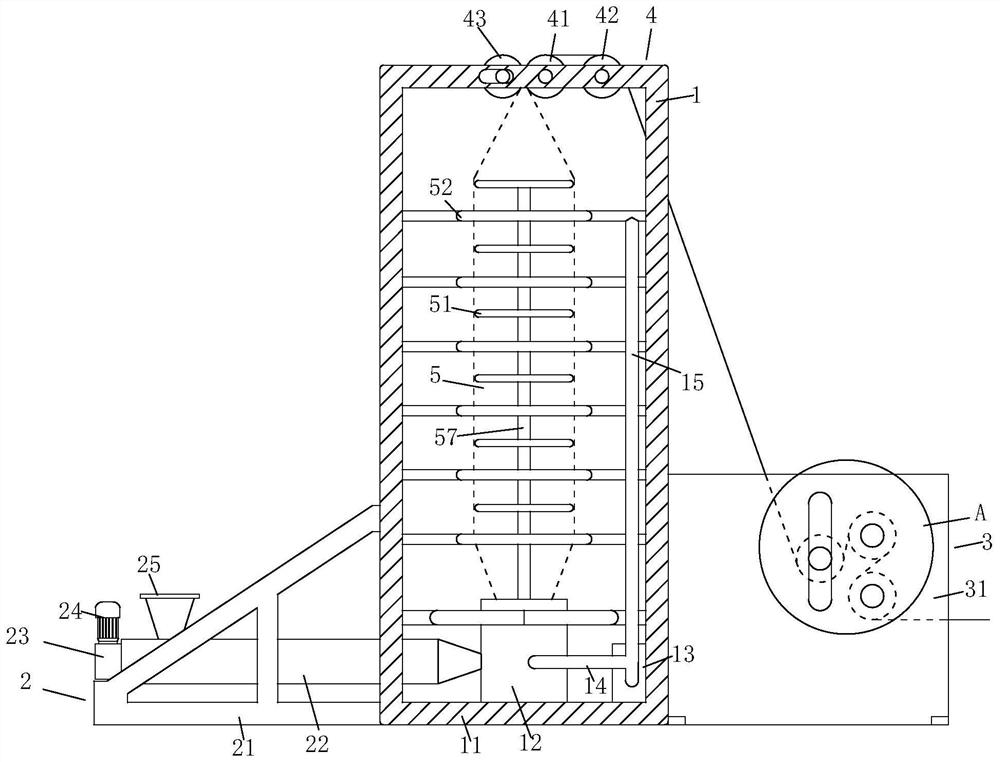

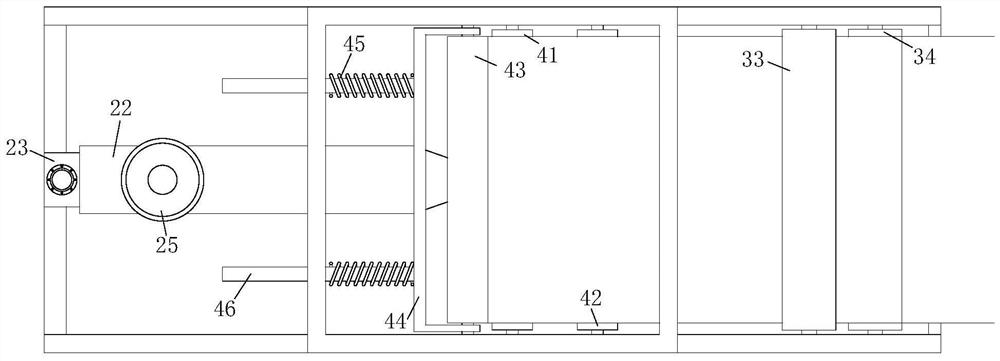

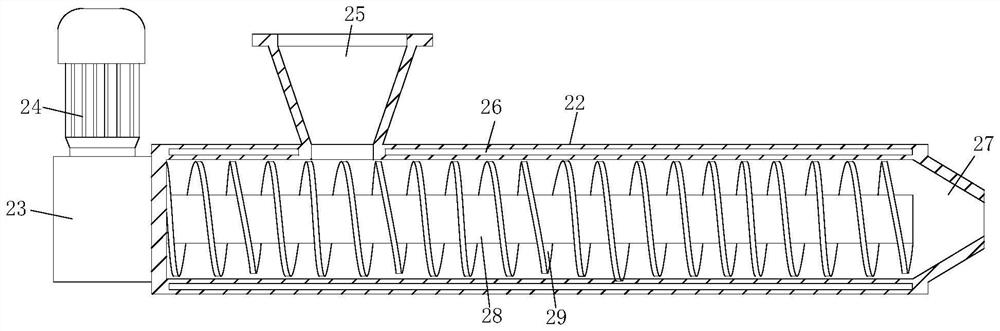

[0028] Such as Figure 1-Figure 7 As shown, a kind of plastic film blowing machine of the present invention comprises film blowing mechanism 1, feeding mechanism 2, tensioning mechanism 3, exhaust mechanism 4 and cooling system 5, and described feeding mechanism 2 and tensioning Mechanism 3 is respectively arranged on the front and rear sides of blown film mechanism 1, and the top of said blown film mechanism 1 is provided with exhaust mechanism 4, and said blown film mechanism 1 is provided with cooling system 5, and described blown film mechanism 1 includes vertical Frame 11, blown film die head 12, blower fan 13, inner guide pipe 14 and outer guide pipe 15, the bottom side of described stand 11 is fixedly connected with blow molding die head 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com