A fuel dispenser that starts and records information through a mobile storage identification device

A technology for identifying devices and recording information, applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., can solve problems such as increasing the difficulty of personnel management in gas stations, difficult maintenance, and troublesome gas stations. To achieve the effect of facilitating internal management and assessment, improving the degree of safety precautions, and reducing the requirements for technical capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

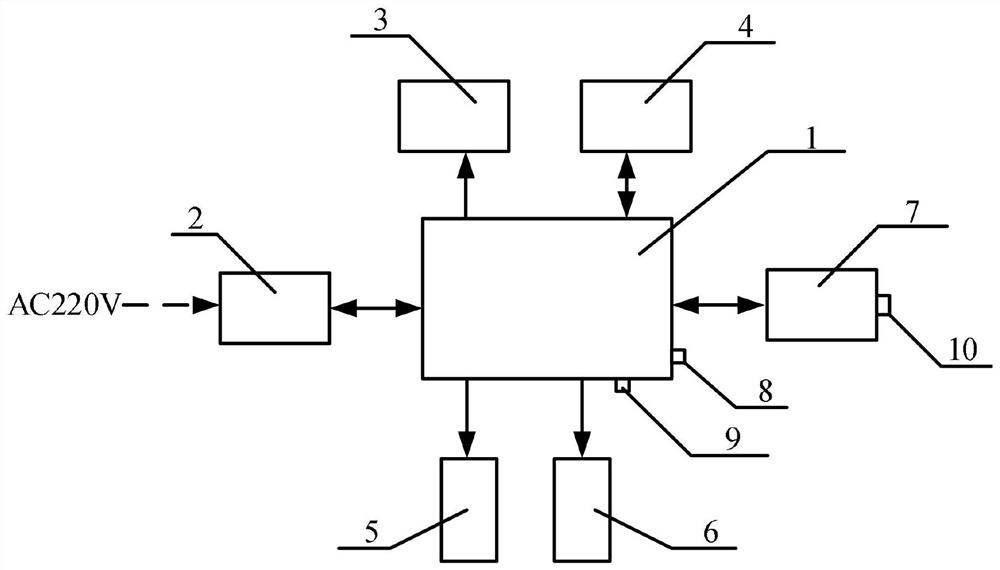

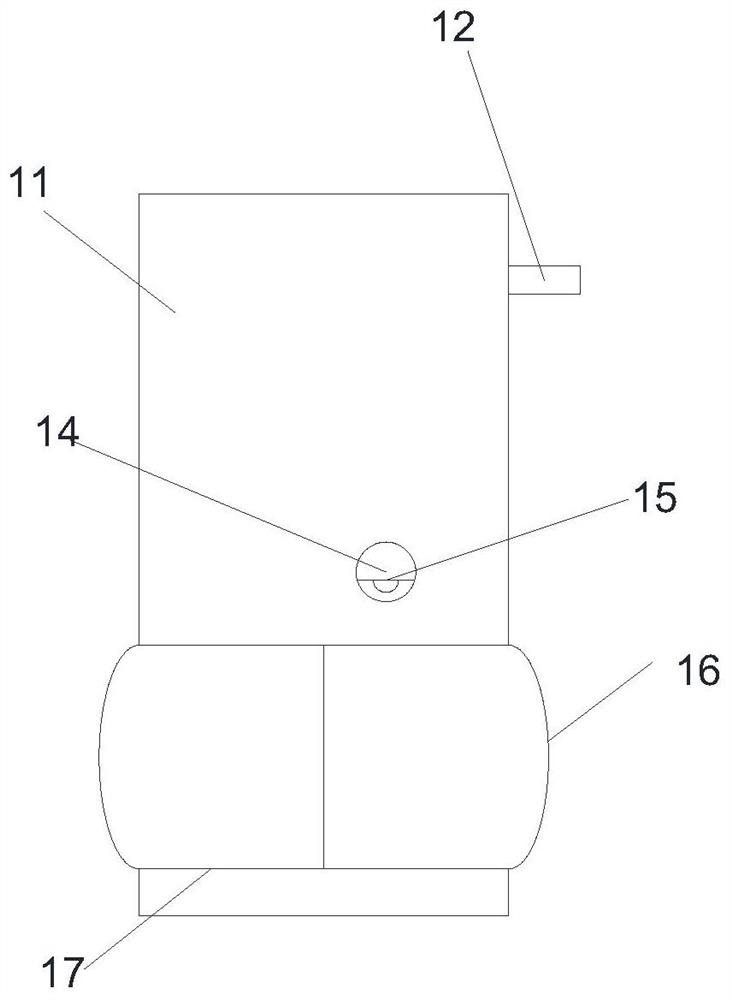

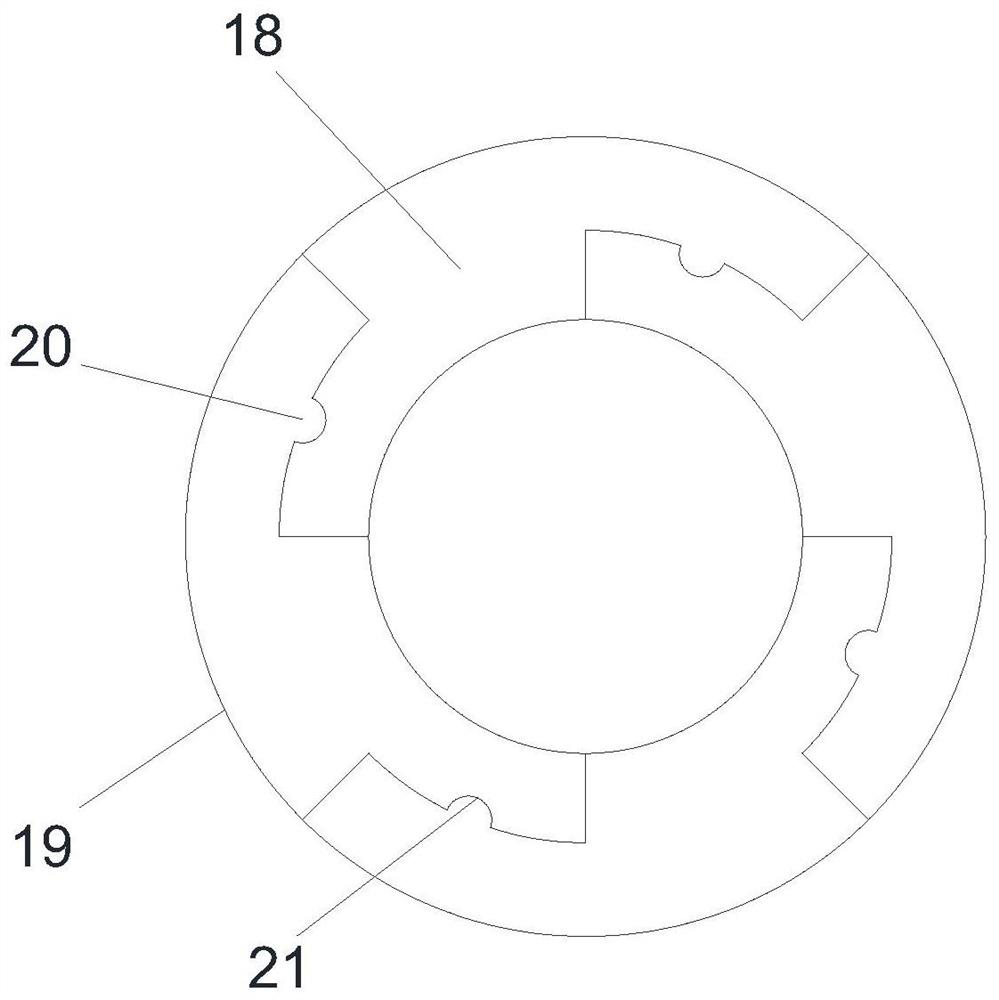

[0022] Example 1 see Figure 1-4 , the present invention provides the following technical solutions: a fuel dispenser that starts and records information through a mobile storage identification device, a body, a mobile storage identification device and a control system. The end control system, the control system is also equipped with an identification module, the control system is provided with a USB control interface on the outside of the body, the USB control interface is used to connect the mobile storage identification device and the control system, and transmit information; the mobile storage identification device There is an account module that is identified by the identification module and logged into the control system to control and start. The mobile storage identification device is connected to the control system through the USB control interface. Account login information and record the amount of refueling under this account and generate a form to save in the data r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com