Rainwater collecting and self-recycling system for high-rise buildings

A rainwater collection and high-rise building technology, applied in construction, general water supply conservation, water supply installations, etc., can solve problems such as reducing practicability, affecting later use, and inability to filter rainwater impurities, to improve work efficiency, avoid disinfection, reduce The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

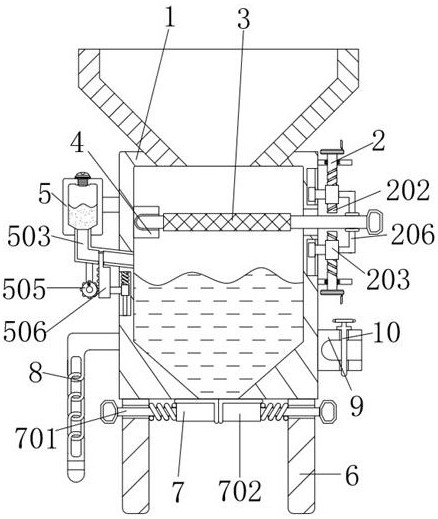

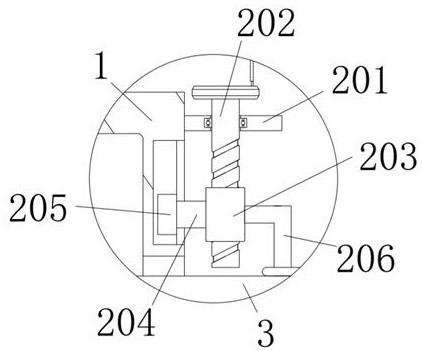

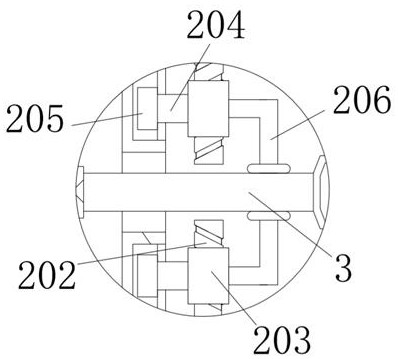

[0032] A high-rise building rainwater collection self-recycling system, including a first shell 1 and a pillar 6, the left and right sides of the bottom of the first shell 1 are fixedly connected with the pillar 6, the top of the first shell 1 is connected with an opening, the first shell 1 A fixing device 2 is provided above the right side of the upper side, and the fixing device 2 includes a thin plate 201, a screw mandrel 202, a block 203, a first short plate 204, a slider 205 and a curved plate 206, and the left end of the thin plate 201 is connected to the right side of the first housing 1. The top is fixedly connected, the inner wall of the thin plate 201 is rotationally connected with the upper outer wall of the screw rod 202 through the bearing, the screw rod 202 can rotate through the bearing, the top of the screw rod 202 is provided with a handle, and the lower part of the outer wall of the screw rod 202 is connected with the inner wall of the block 203 by threads , t...

Embodiment 2

[0034] As an option, see figure 1 , 4And 5, high-rise building rainwater collection self-recycling system, the left side of the first shell 1 is provided with unloading device 5, unloading device 5 comprises horizontal plate 501, material box 502, inclined pipe 503, vertical plate 504, gear 505, Rack 506, second short plate 507, sliding sleeve 508, slide bar 509 and first spring 510, the right end of cross plate 501 is fixedly connected with the upper left side of first shell 1, the left end of cross plate 501 is connected with the top of the material box 502 The right side is fixedly connected, the top of the material box 502 is provided with a rubber stopper, the bottom of the material box 502 is connected with an inclined pipe 503, and the left side of the bottom of the inclined pipe 503 is fixed with a vertical plate 504, and the bottom of the vertical plate 504 is connected to the gear through the pin shaft. The rear end face of 505 is rotated and connected, and the gear...

Embodiment 3

[0037] As an option, see figure 1 and 6 , high-rise building rainwater collection self-recycling system, the right side of the first shell 1 is fixedly connected with a thick plate 9, the inside of the thick plate 9 is provided with a thin rod 10, the top of the thin rod 10 is provided with a handle, the outer wall of the thin rod 10 is connected to the The inner walls of the upper and lower sides of the thick plate 9 are fitted with a gap, and the thin rod 10 can move up and down on the inner wall of the thick plate 9. A chain 8 is arranged on the left side of the first shell 1, and the right side of the chain 8 is connected to the left side of the first shell 1. The bottom is fixedly connected, and the bottom of the first shell 1 is provided with a switch device 7. The switch device 7 includes a long rod 701, a wide plate 702, a second spring 703 and a handle 704. There is a gap between the outer wall of the long rod 701 and the upper inner wall of the left pillar 6. Cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com