Photosensitive color-changing anti-counterfeit barcode and preparation method thereof

A photosensitive discoloration and barcode technology, which is applied in the field of anti-counterfeiting barcodes, can solve the problems of being easy to be imitated and not being able to realize anti-counterfeiting, and achieve the effects of good anti-counterfeiting effect, low cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

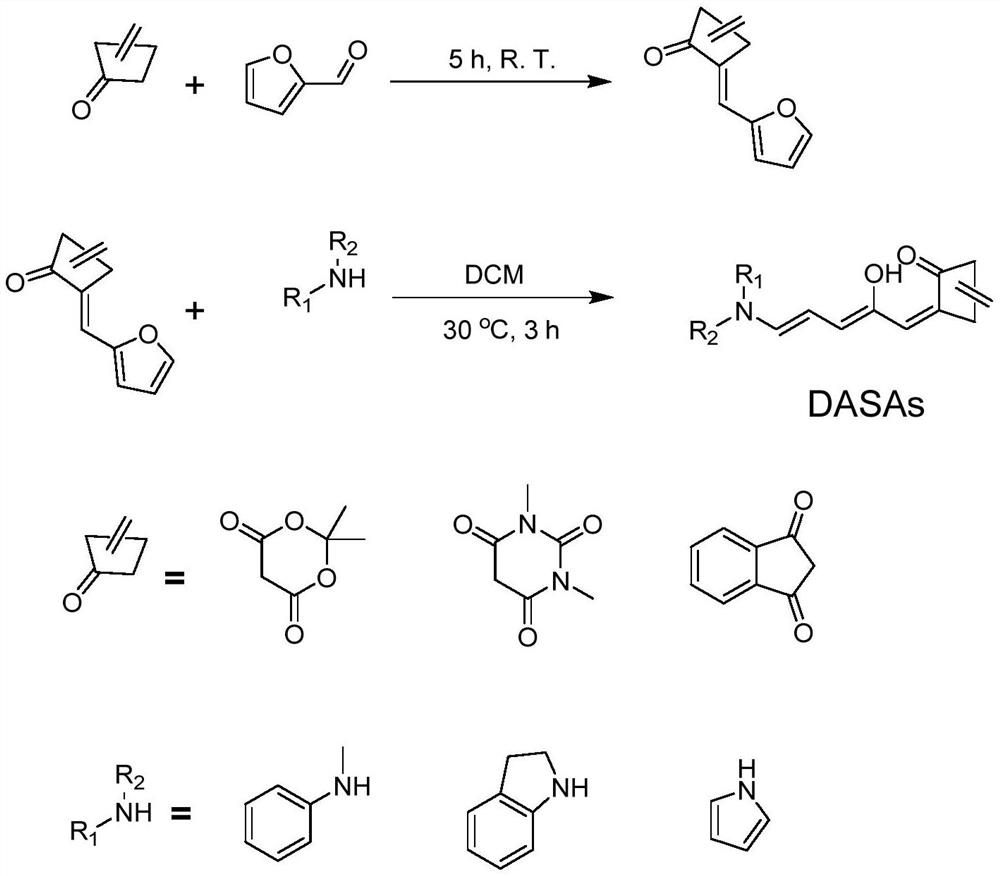

[0026] A photosensitive color-changing anti-counterfeiting barcode, the preparation method thereof comprises the following steps:

[0027] (1) Preparation of intermediate: Stir barbituric acid and furfural at 40°C for 5 hours, then wash with water, filter with suction, extract, dry, filter with suction twice, purify by column chromatography, and rotate to evaporate to obtain the intermediate; Among them, the molar ratio of barbituric acid and furfural is 1:1; successively use saturated sodium bisulfite solution and saturated sodium chloride solution to extract, use anhydrous magnesium sulfate to dry, and the eluent during column chromatography purification is dichloro methane;

[0028] (2) Preparation of DASAs molecules: Dissolve the intermediate obtained in step (1) in dichloromethane, then add N-methylaniline, stir at a constant temperature of 30°C for 3 hours, then sequentially purify by column chromatography and rotary steam to obtain DASA molecule; wherein, intermediate ...

Embodiment 2

[0031] A photosensitive color-changing anti-counterfeiting barcode, the preparation method thereof comprises the following steps:

[0032] (1) Intermediate preparation: Stir Michaelis acid and furfural at 40°C for 5 hours, then successively wash with water, filter with suction, extract, dry, filter with suction twice, purify by column chromatography, and rotate to evaporate to obtain the intermediate; , Michaelis acid and furfural molar ratio is 1:1; successively use saturated sodium bisulfite solution and saturated sodium chloride solution to extract, use anhydrous magnesium sulfate to dry, eluent is dichloromethane during column chromatography purification;

[0033] (2) Preparation of DASAs molecules: Dissolve the intermediate obtained in step (1) in dichloromethane, then add N-methylaniline, stir at a constant temperature of 30°C for 3 hours, then sequentially purify by column chromatography and rotary steam to obtain DASA molecule; wherein, the molar ratio of the intermedi...

Embodiment 3

[0036] A photosensitive color-changing anti-counterfeiting barcode, the preparation method thereof comprises the following steps:

[0037] (1) Preparation of intermediates: Stir 1,3-indandione and furfural at 40°C for 5 hours, then wash with water, filter with suction, extract, dry, filter with suction twice, purify with column chromatography and rotary evaporate, The intermediate is obtained; wherein, the molar ratio of 1,3-indandione and furfural is 1:1; successively use saturated sodium bisulfite solution and saturated sodium chloride solution to extract, use anhydrous magnesium sulfate to dry, column chromatography The eluent is dichloromethane during purification;

[0038] (2) Preparation of DASAs molecules: Dissolve the intermediate obtained in step (1) in dichloromethane, then add indoline, stir at a constant temperature of 30°C for 3 hours, then sequentially purify by column chromatography and rotary steam to obtain DASA Molecule; Wherein, intermediate and indoline mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com