High-strength, anti-flaming and waterproof polyimide fire control fabric and preparation method thereof

A polyimide and polyimide fiber technology, applied in wet spinning, fabric surface trimming, single-component synthetic polymer rayon, etc. The problems of low saturation force and low pilling resistance of imine fibers can improve the tensile breaking strength and pilling resistance, good tensile breaking strength, and increase the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

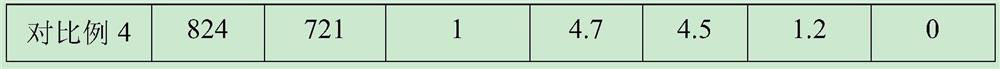

Examples

Embodiment 1

[0024] The polyamic acid spinning solution is spun according to the wet spinning process, the shape of the spinneret is circular with grooves on the surface, and the obtained polyamic acid precursor is imidized by thermal amidation to obtain The fine-denier polyimide fiber filament with circular grooved cross-section, the fiber breaking strength is 21cN / dtex, and the specification is 200D; the fine-denier polyimide fiber filament with special-shaped cross-section is washed with water, oiled, and dried , and then 2 bundles of fibers are twisted together to obtain a polyimide filament with a specification of 400D; the polyimide filament and the specification are 30 polyimide yarns according to a weight ratio of 20%:80 % ratio for blending, the surface density of the fabric is 200gsm; the waterproof padding treatment is carried out on the fabric, and the waterproof finishing solution is diluted with DuPont's Zelan R3 fluorine-free waterproof finishing agent and an equal amount of ...

Embodiment 2

[0026] The polyamic acid spinning solution is spun according to the wet spinning process, and the shape of the spinneret is a trilobal shape with grooves on the surface, and the obtained polyamic acid precursor is imidized by thermal amidation to obtain Fine denier polyimide fiber filament with trilobal grooved section, fiber breaking strength 17cN / dtex, specification 100D; this fine denier polyimide fiber filament with trilobal grooved section After washing, oiling and drying, two bundles of fibers are twisted one by one to obtain polyimide filaments with a specification of 200D; polyimide filaments and polyimide yarns with a specification of 40 According to the proportion of 10% by weight: 90%, the blended fabric is made, and the surface density of the fabric is 180gsm; the waterproof padding treatment is carried out on the fabric, and the waterproof finishing solution is diluted with DuPont's Zelan R3 fluorine-free waterproof finishing agent and an equal amount of water, pH ...

Embodiment 3

[0028] The polyamic acid spinning solution is spun according to the wet spinning process, the shape of the spinneret is Y-shaped with grooves on the surface, and the obtained polyamic acid precursor is imidized by thermal amidation to obtain The fine-denier polyimide fiber filament with Y-shaped grooved cross-section has a fiber breaking strength of 18cN / dtex, and the specification is 50D; the fine-denier polyimide fiber filament with Y-shaped grooved cross-section is washed, Oiling, drying, and then 4 bundles of fibers are twisted together to obtain polyimide filaments with a specification of 200D; the polyimide filaments and polyimide yarns with a specification of 20 The proportion of 50%:50% is blended, and the surface density of the fabric is 250gsm; the waterproof padding treatment is carried out on the fabric, and the waterproof finishing solution is diluted with DuPont's Zelan R3 fluorine-free waterproof finishing agent and an equal amount of water, and the pH value is 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com