Production process of functional bamboo fiber fabric

A bamboo fiber fabric and bamboo fiber technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems that plague the development of bamboo fiber textiles and restrain the consumer market, so as to reduce the breakage or slipping and protrude hairiness, Reduced yarn hairiness and end breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

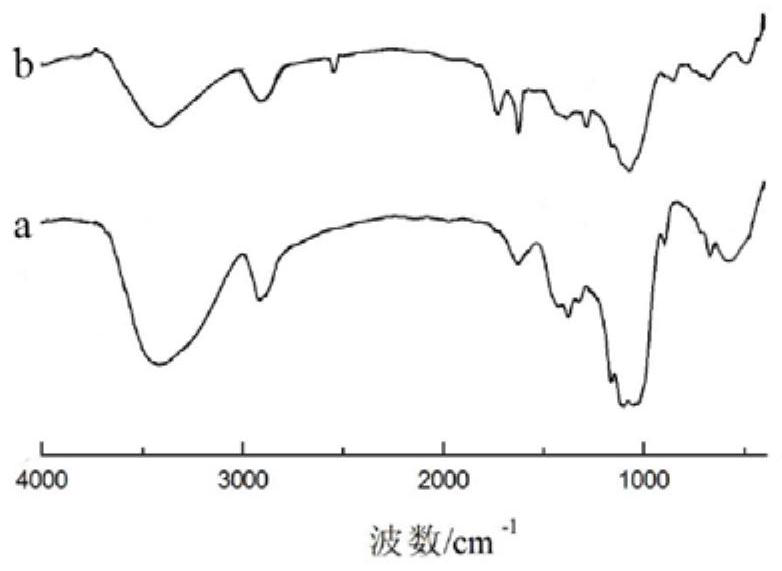

Method used

Image

Examples

Embodiment 1

[0056] The preparation method of sorbic acid derivative shown in formula I:

[0057] Add 1mmol sorbic acid into a 50mL round bottom flask, add 2mL DMF at 0°C, and drop 0.14mL triethylamine to obtain liquid A;

[0058] Add 1mmol BOP to another 50mL round bottom flask, add 2mL dichloromethane and 1.15mmol glutathione at 0°C to obtain liquid B;

[0059] Slowly add solution B to solution A at 0°C, stir at 0°C for 30 minutes, then stir at room temperature for 2 hours, follow the reaction by TLC (developing solvent is dichloromethane-methanol=10:1), after the reaction, Dichloromethane was evaporated to dryness, diluted with 15 mL of water, extracted with 30 mL of ethyl acetate, and the ethyl acetate layer was extracted with 1 mol / L HCl to wash away triethylamine in the reaction solution. Wash with saturated aqueous sodium bicarbonate solution to neutralize excess HCl in the previous step. Wash with saturated saline. Then the organic layer was dried over anhydrous magnesium sulfat...

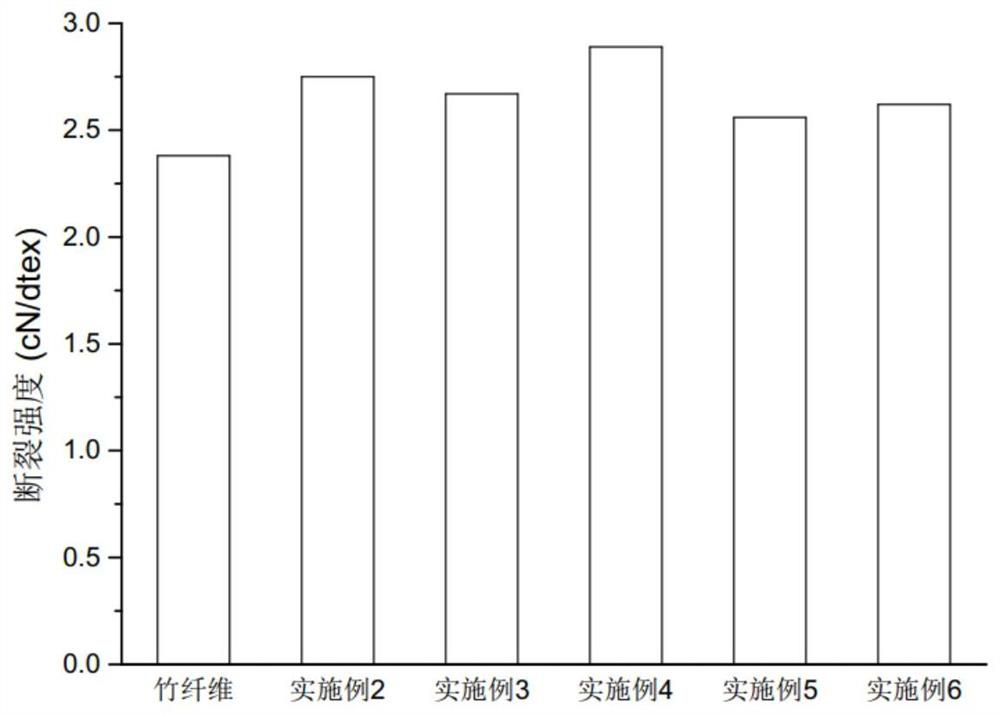

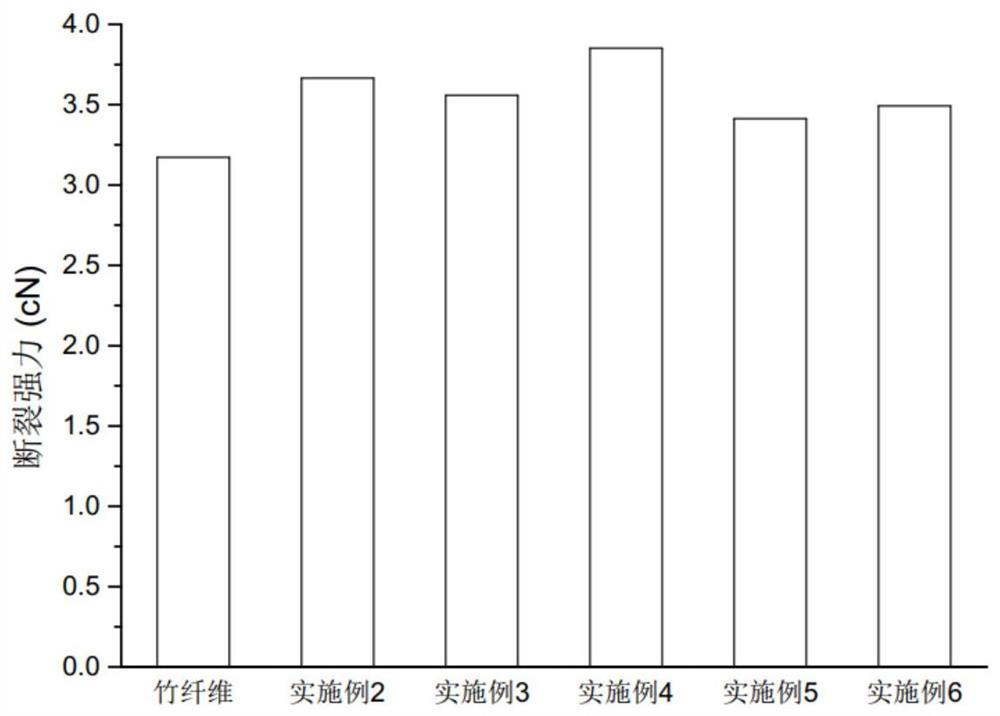

Embodiment 2

[0064] A modification method of above-mentioned bamboo fiber, comprising:

[0065] Step 1: the utilization concentration of bamboo fiber is 5% pretreatment solution (the NaOH of equal concentration and H 2 o 2 Mixed solution) pretreatment 2h, after finishing, rinse bamboo fiber with distilled water until the pH of the washing solution is neutral, and dry to obtain pretreated bamboo fiber;

[0066] Step 2: join pretreatment bamboo fiber and sodium hypophosphite in 8mM sorbic acid derivative solution, the consumption ratio of pretreatment bamboo fiber, sorbic acid derivative and sodium hypophosphite is 1g:100mL:0.15g, sorbic acid derivative The concentration of the solution is as follows: stirring and reacting at 125° C. for 1.5 h, cooling, rinsing the bamboo fiber with distilled water until the pH of the rinsing solution is neutral, and drying to obtain functional bamboo fiber.

Embodiment 3

[0068] A modification method of above-mentioned bamboo fiber, comprising:

[0069] Step 1: the utilization concentration of bamboo fiber is 5% pretreatment solution (the NaOH of equal concentration and H 2 o 2 Mixed solution) pretreatment 2h, after finishing, rinse bamboo fiber with distilled water until the pH of the washing solution is neutral, and dry to obtain pretreated bamboo fiber;

[0070] Step 2: join pretreatment bamboo fiber and sodium hypophosphite in 8mM sorbic acid derivative solution, the consumption ratio of pretreatment bamboo fiber, sorbic acid derivative and sodium hypophosphite is 1g:100mL:0.18g, sorbic acid derivative The concentration of the solution is as follows: stirring and reacting at 125° C. for 1.5 h, cooling, rinsing the bamboo fiber with distilled water until the pH of the rinsing solution is neutral, and drying to obtain functional bamboo fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com