Purification system for surface sizing starch glue solution and application of purification system

A technology of surface sizing starch and purification system, which is applied in chemical instruments and methods, water repellent addition, pulp raw material addition process, etc., can solve problems such as poor slag removal effect of glue solution, and achieve the effect of reducing easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

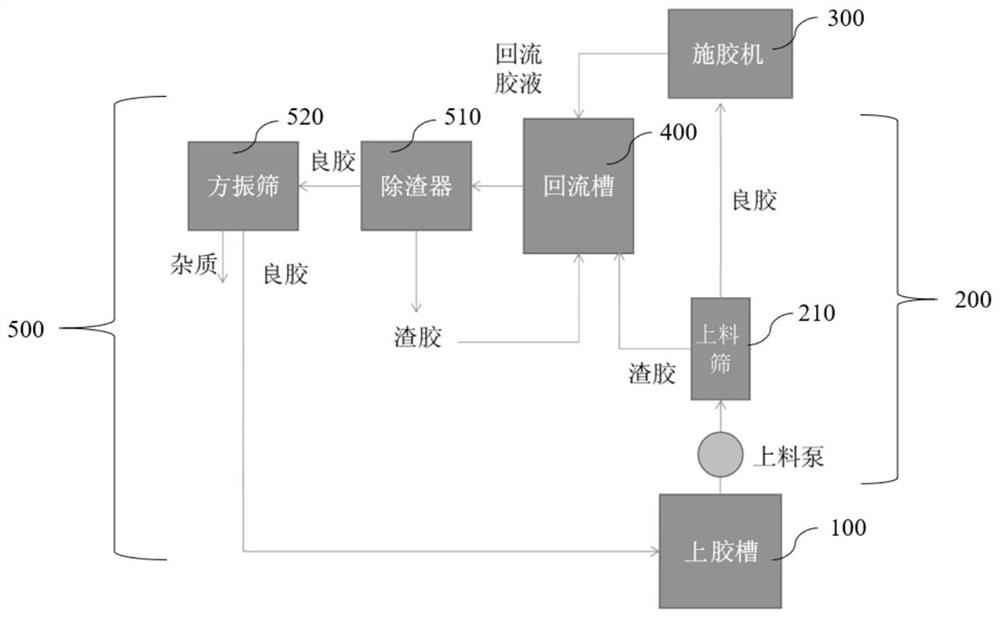

[0038] A purification system for surface sizing starch glue of this embodiment includes a sizing tank 100, a loading screen 210, a sizing machine 300, a return tank 400, a slag remover 510, and a square vibration, which are connected by pipes in sequence and form a loop. A sieve 520, where the glue in the gluing tank 100 flows to the upper sieve 210 and is left in the sizing machine 300 to form a gluing unit 200. The gluing unit 200 removes impurities from the gluing tank 100 and passes it into The upper and lower sizing sticks in the sizing machine 300 coat the front and back of the paper with glue and form a film; the glue returned from the sizing machine 300 enters the return tank 400 and passes through the slag remover 510 and the square vibrating screen After 520 impurity removal, it flows to the upper glue tank 100 to form a glue-back unit. The glue-back unit recovers the excess glue from the sizing machine 300, and performs a series of purification and impurity removal pr...

Embodiment 2

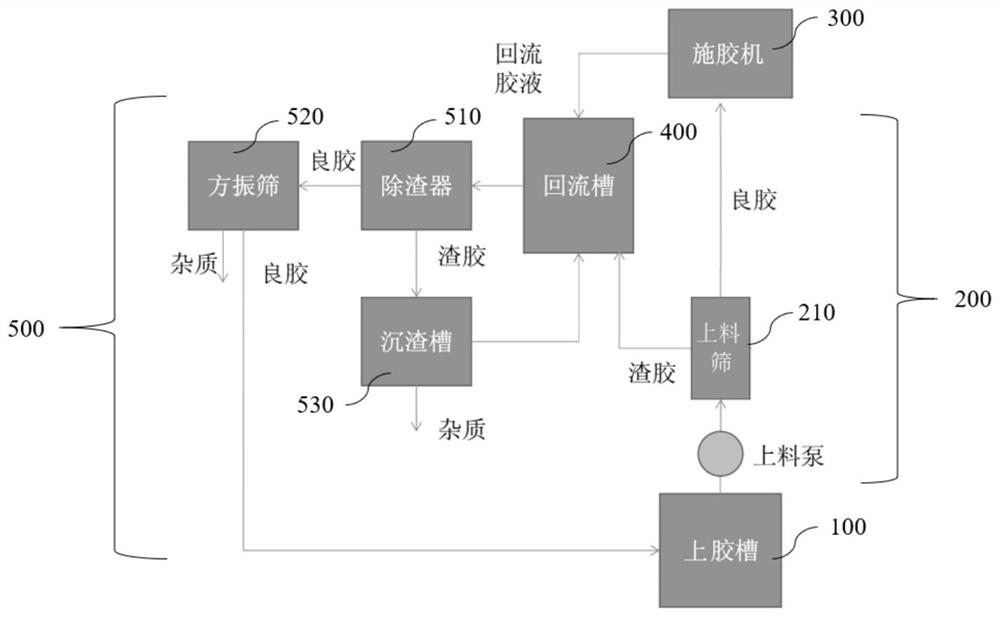

[0043] The purification system of the surface sizing starch glue solution of this embodiment is basically the same as that of Embodiment 1, and the difference is that a sediment tank 530 is also provided in the reflux unit 500.

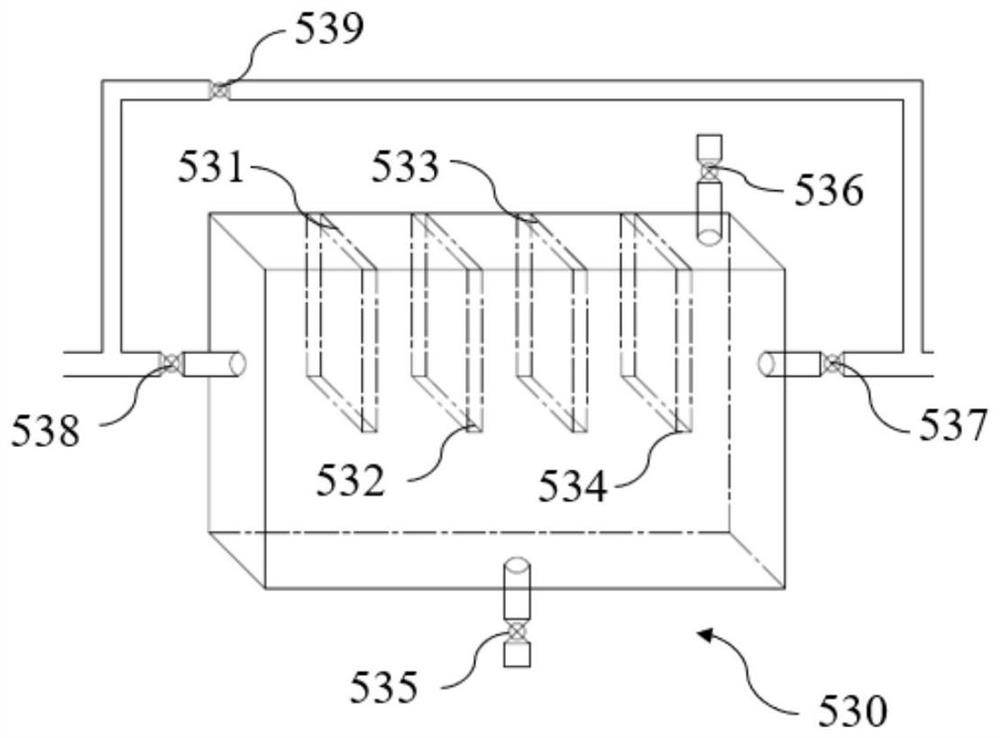

[0044] Combine figure 2 The feed port of the slag tank 530 is connected to the slag discharge port of the slag remover 510 for recovering and processing the slag discharged from the slag remover 510. The structure of the sediment tank 530 is as image 3 As shown, a first baffle 531, a second baffle 532, a third baffle 533, and a fourth baffle 534 are arranged side-by-side at the top. After the slag discharged from the cleaner 510 enters the slag tank 530, it passes through the Disturbance of a baffle 531, a second baffle 532, a third baffle 533, and a fourth baffle 534, under the action of inertia, heavy slag sinks into the bottom of the slag tank 530, and the bottom of the slag tank 530 is provided with a slag discharge port, The closing of the slag po...

Embodiment 3

[0047] The purification system of the surface sizing starch glue solution of this embodiment is basically the same as that of the embodiment 2, and the difference lies in that: the gluing unit 200 is provided with two pressure screens connected in series, each of which is a section of pressure screen 211 And the two-stage pressure screen 212, in which the screen slits of the first-stage pressure screen 211 and the second-stage pressure screen 212 are both 80-100 μm.

[0048] Combine Figure 5 As shown, in the gluing unit 200, the glue is transported by the feeding pump from the gluing tank 100 to the pressure screen 211, the pressure at the upper part of the pressure screen 211 is 72Kpa, and the pressure at the lower part of the pressure screen is 57Kpa. , The inlet and outlet pressure difference is set to 15Kpa, the first stage of slag discharged from the bottom of the pressure screen 211 enters the reflux tank 400 for processing, and the good slurry through the first stage of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com