Damping steel base plate with anti-corrosion coating for railway track base plate

An anti-corrosion coating, railway track technology, applied in the field of damping steel backing plates, can solve the problems of easy insect erosion of base boards, short service life of backing plates, single damping structure, etc., to prevent insect erosion, increase service life, The effect of preventing insect erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

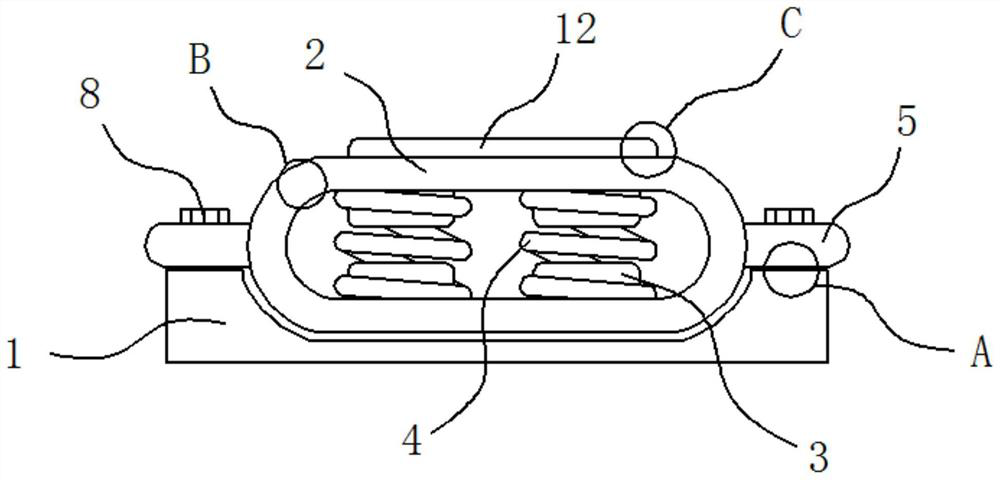

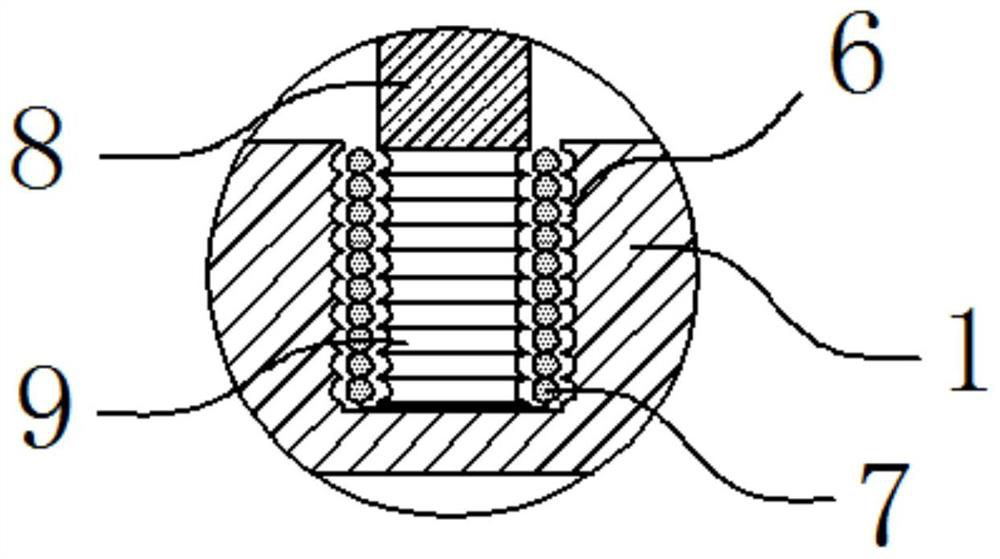

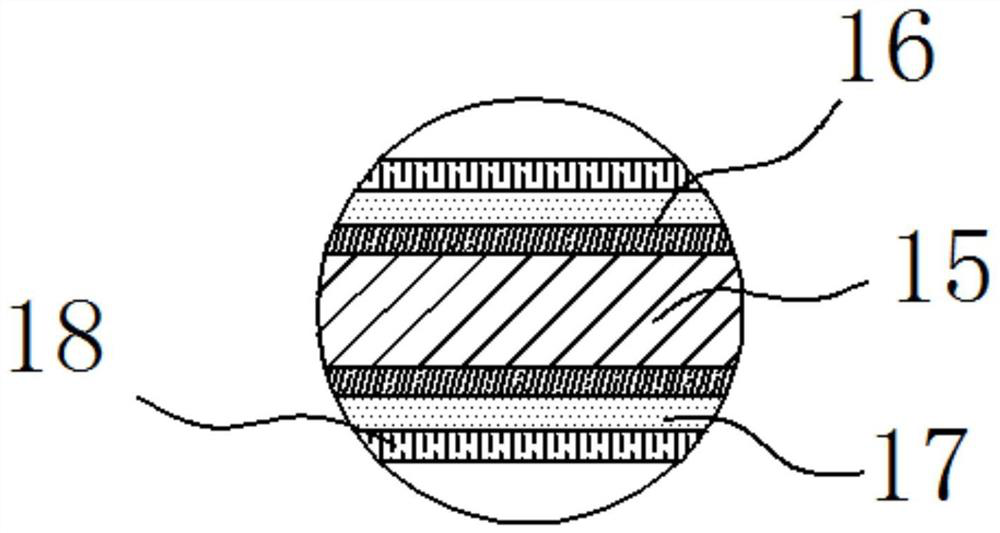

[0031] See Figure 1-Figure 5 The present invention provides a technical solution: a damping steel backing plate with anti-corrosion coating for railway track backing plates, comprising a rail backing plate body 1 on which a damping steel backing plate body 2 is provided, The upper and lower ends of the steel backing plate body 2 are welded with spring fixing blocks 3, the spring fixing blocks 3 at both ends are fixedly connected with springs 4, and the two ends of the damping steel backing plate body 2 are welded with fixing plates 5 and rail pads. Both ends of the plate body 1 are fixedly provided with threaded grooves 6, and the internal threads of the threaded grooves 6 at both ends are connected with threaded barrels 7, and the fixed plate 5 is fixedly connected with the rail backing plate body 1 through the fixed threaded bolts 8, and the top of the threaded bolts 8 is fixed. A threaded head 9 is fixed, and the threaded head 9 is threadedly connected with the threaded bar...

Embodiment 2

[0046] Embodiment 2: The difference from Embodiment 1 is the preparation scheme of the insecticidal layer 19:

[0047] A damping steel backing plate with anti-corrosion coating for railway track backing plates. The damping steel backing plate includes a rail backing plate body 1. A damping steel backing plate body 2 is provided on the rail backing plate body 1. Both ends are welded with a spring fixing block 3, the spring fixing blocks 3 at both ends are fixedly connected with a spring 4, the two ends of the damping steel backing plate body 2 are welded with fixing plates 5, and the two ends of the rail backing plate body 1 are fixedly provided A threaded groove 6 is threaded inside the threaded grooves 6 at both ends with a threaded barrel 7. The fixing plate 5 is fixedly connected to the rail backing plate body 1 through a fixing threaded bolt 8, and a threaded head 9 is fixed on the top of the fixed threaded bolt 8. 9 is screwed to the threaded cylinder 7. When in use, the dam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com