Rotary machine weak fault signal extraction method based on order analysis and sparse coding

A fault signal, sparse coding technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc. Adverse effects, high flexibility and adaptability, the effect of eliminating the effects of sparse coding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

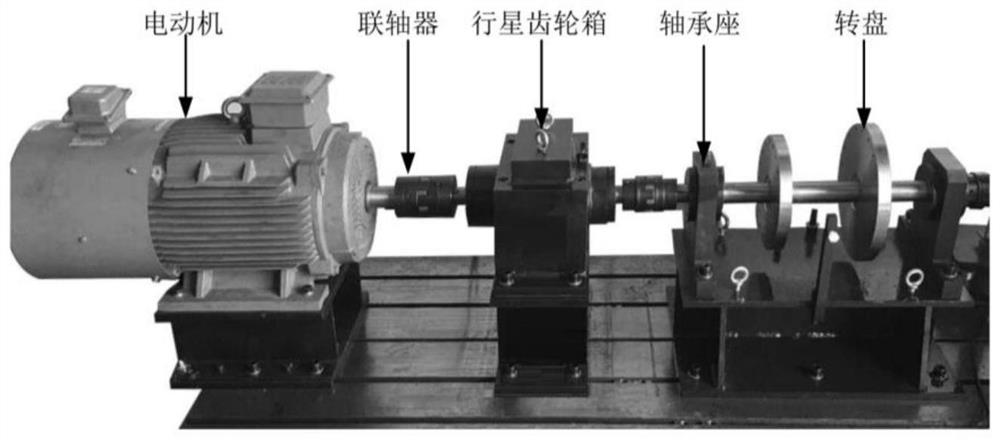

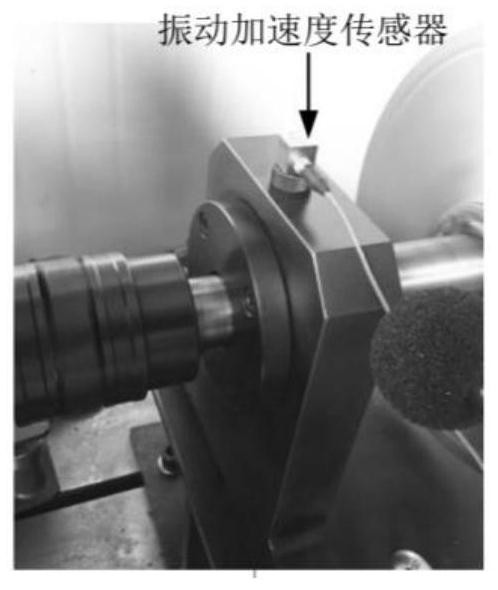

Examples

Embodiment Construction

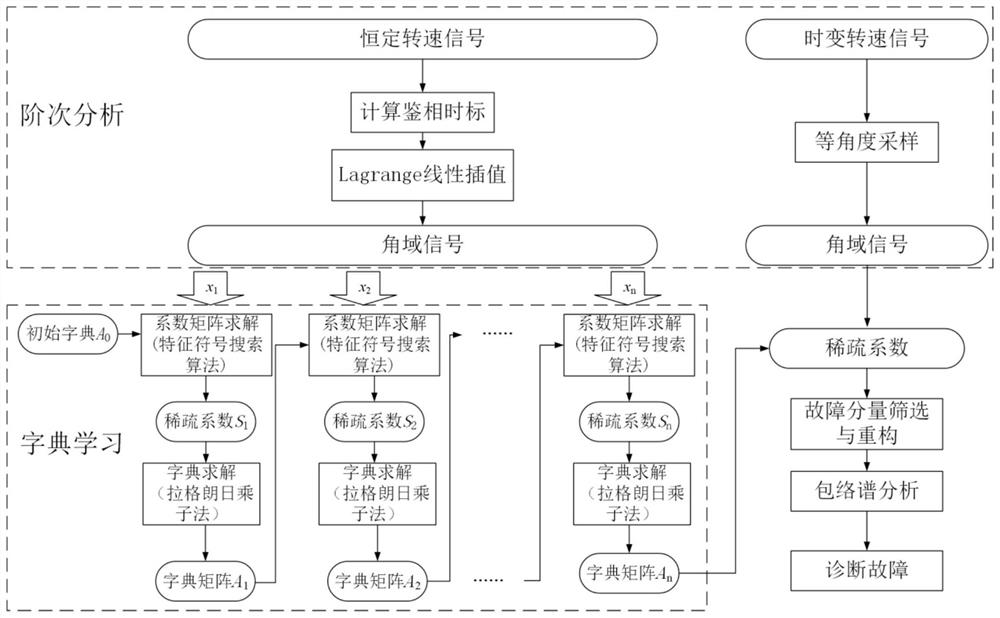

[0034] A method for extracting weak fault signals of rotating machinery based on order analysis and sparse coding of the present invention comprises the following steps:

[0035] Step 1. Order analysis of sample data: Carry out angle domain resampling on the collected fault signal. Since the rotational speed n(t) is constant, the value of instantaneous frequency f can be deduced by calculation order analysis method: f(t)= n(t) / 60; by solving 2πn(T n -T 0 )=nΔθ to calculate the phase identification time scale T n , where T 0 is the initial time of the speed fitting curve, Δθ is the sampling interval of equiangular sampling, and the sampling interval must satisfy the Nyquist sampling theorem at the same time; then the original vibration signal of the rotor is resampled by Lagrange linear interpolation to obtain equiangular Interval angle domain data; the Lagrange linear interpolation relation is t i The time coordinate in the signal is less than or equal to T n The most r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com