Asphalt mixture mixing temperature determination method based on surface energy theory

A technology for asphalt mixture and determination method, which is applied in the direction of physical/chemical changes in thermometers, chemical instruments and methods, mixers, etc., can solve problems that cannot reflect the adhesion of asphalt and aggregates, and achieve scientific results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

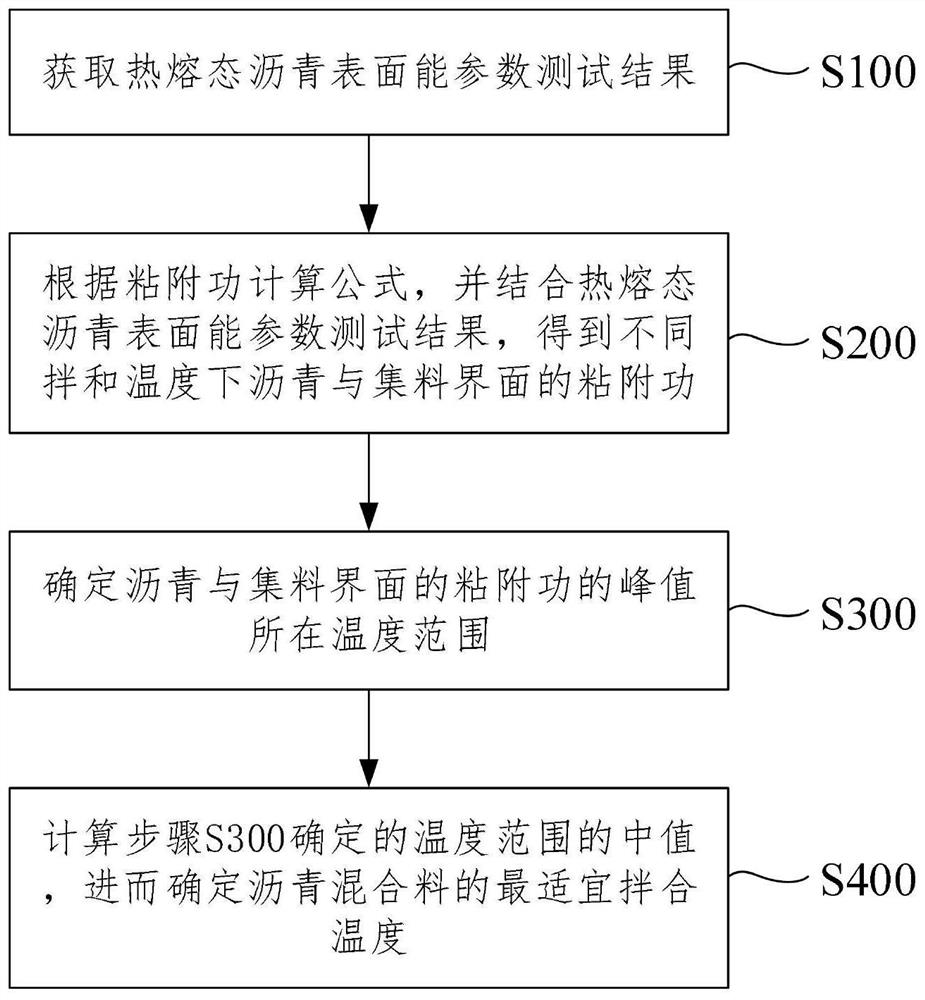

[0042] Such as figure 1 As shown, a method for determining the mixing temperature of asphalt mixture based on the surface energy theory in this embodiment includes the following steps: step S100, obtaining the test results of the surface energy parameters of hot-melt asphalt; step S200, according to the adhesion work calculation formula , and combined with the test results of the surface energy parameters of hot-melt asphalt, the adhesion work of the asphalt-aggregate interface at different mixing temperatures is obtained; step S300, determining the temperature range of the peak value of the adhesion work of the asphalt-aggregate interface; step S400, Calculate the median value of the temperature range determined in step S300, and then determine the optimum mixing temperature of the asphalt mixture.

[0043]The technical effect achieved by this embodiment is: through a method for determining the asphalt mixture mixing temperature based on the surface energy theory in this embo...

Embodiment 2

[0063] Such as figure 1 and Figure 5 As shown, a method for determining the mixing temperature of asphalt mixture based on the surface energy theory in this embodiment includes all the technical features in Embodiment 1. In addition, the hot-melt asphalt surface energy parameter test obtained in step S100 The method includes the following steps:

[0064] Step S110, obtaining the contact angle between the hot-melt asphalt to be tested and three known aggregates;

[0065] Step S120, solving the linear equations to obtain the surface energy parameters of the hot-melt asphalt:

[0066]

[0067] Among them, γ s , gamma l Indicates the surface energy of solid and liquid, respectively, in mJ m -2 ; sl Indicates the solid-liquid interface energy, in mJ m -2 ; s represents the known aggregate; a represents the hot-melt asphalt to be tested; θ represents the contact angle between the hot-melt asphalt to be tested and the known aggregate; 1, 2, and 3 represent three known ag...

Embodiment 3

[0071] Such as figure 1 and Figure 5 As shown, a method for determining the mixing temperature of asphalt mixture based on the surface energy theory in this embodiment includes all the technical features in Embodiment 2. In addition, in step S110, the hot-melt asphalt to be tested and the obtained The specific experimental steps for knowing the contact angle between aggregates include:

[0072] Step S111, obtaining small stone flakes with a smooth surface: select coarse aggregates with regular shapes and known surface energy parameters and send them to a stone cutting plant, and use water sawing to cut the stones on both sides to obtain small stones with a smooth surface. Control the thickness value of small stones;

[0073]Step S112, polishing the small stone flakes to obtain a flat and smooth surface: washing the cut small stones with clean water and drying them, and then polishing the small stones with water sandpaper to obtain a flat and smooth surface;

[0074] Step S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com