Chip encapsulation testing method and device

A chip mounting and chip technology, which is applied in the field of chip packaging and testing methods and devices, and can solve problems such as the position deviation of the suction nozzle relative to the chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is further described in detail through specific implementation methods:

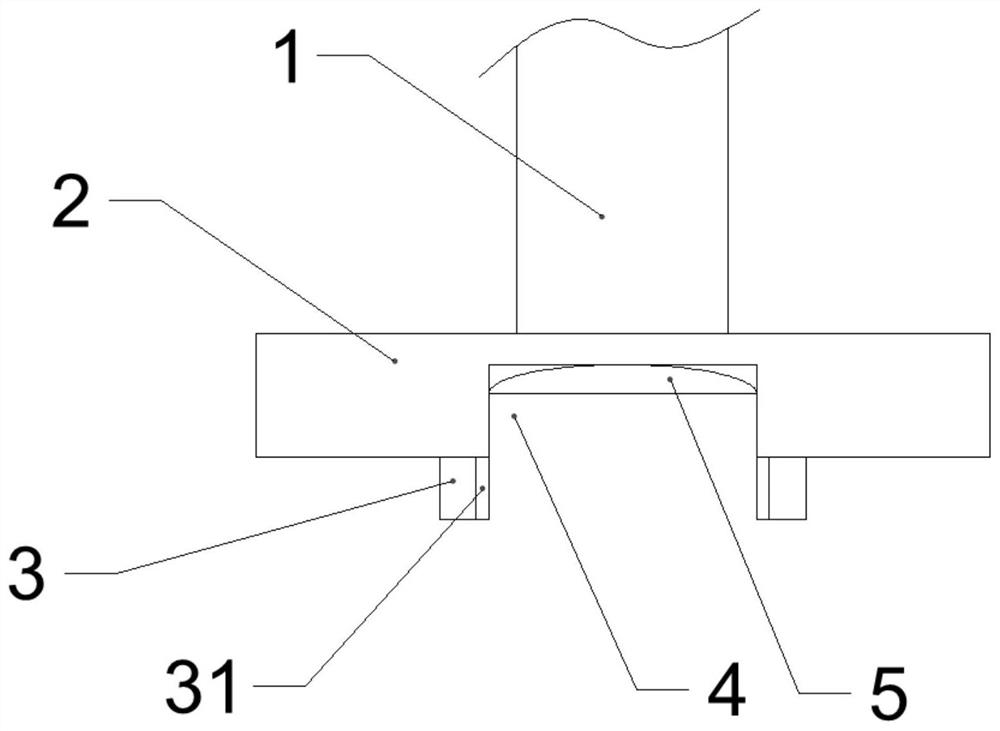

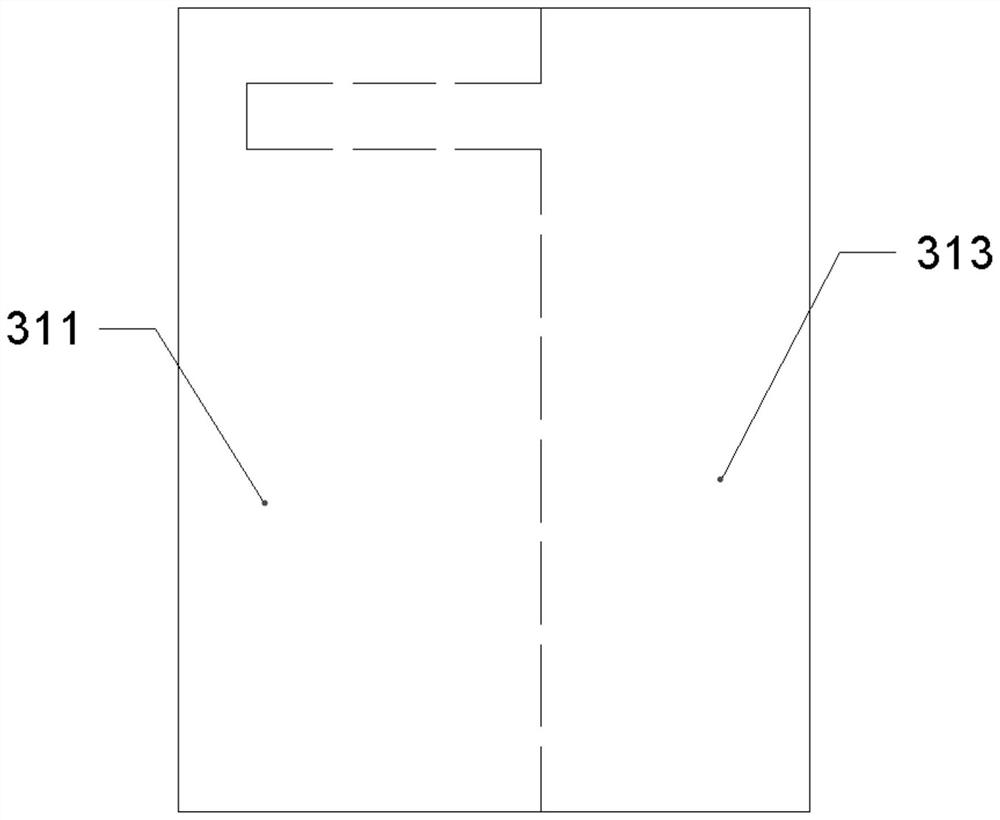

[0037]The reference numerals in the accompanying drawings of the description include: the driving rod 1 , the pick-up plate 2 , the pressing block 3 , the connecting block 31 , the first pressing portion 311 , the second pressing portion 313 , the inner concave portion 4 , and the suction nozzle 5 .

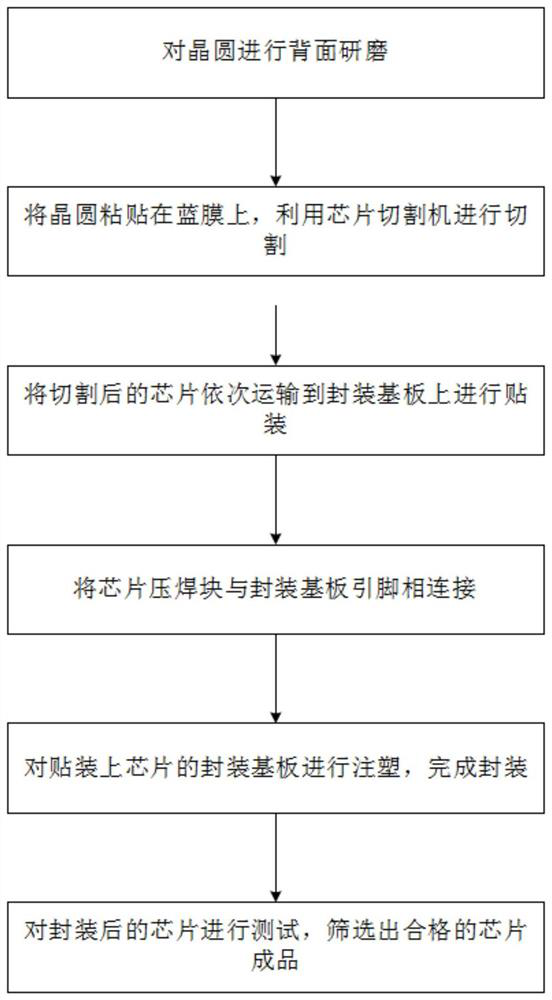

[0038] The embodiment is basically as attached Figure 1 to Figure 3 Shown: a chip packaging and testing method, including the following steps: Wafer thinning step: back grinding the wafer;

[0039] Wafer cutting step: Paste the wafer on the blue film, and cut the wafer with a chip cutting machine;

[0040] Chip mounting step: the pick-up board 2 with the suction nozzle 5 moves according to the preset movement route, and the cut chips are sequentially transported to the packaging substrate for mounting;

[0041] Specifically, the chip mounting step includes the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com