Photoelectric system platform with novel plug-in structure

An optoelectronic system and plug-in technology, applied in the field of optoelectronic systems, can solve problems such as failure of key components, performance degradation of optoelectronic equipment, system paralysis, etc., to achieve the effects of improving electromagnetic compatibility, enhancing electrical continuity, reducing noise and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

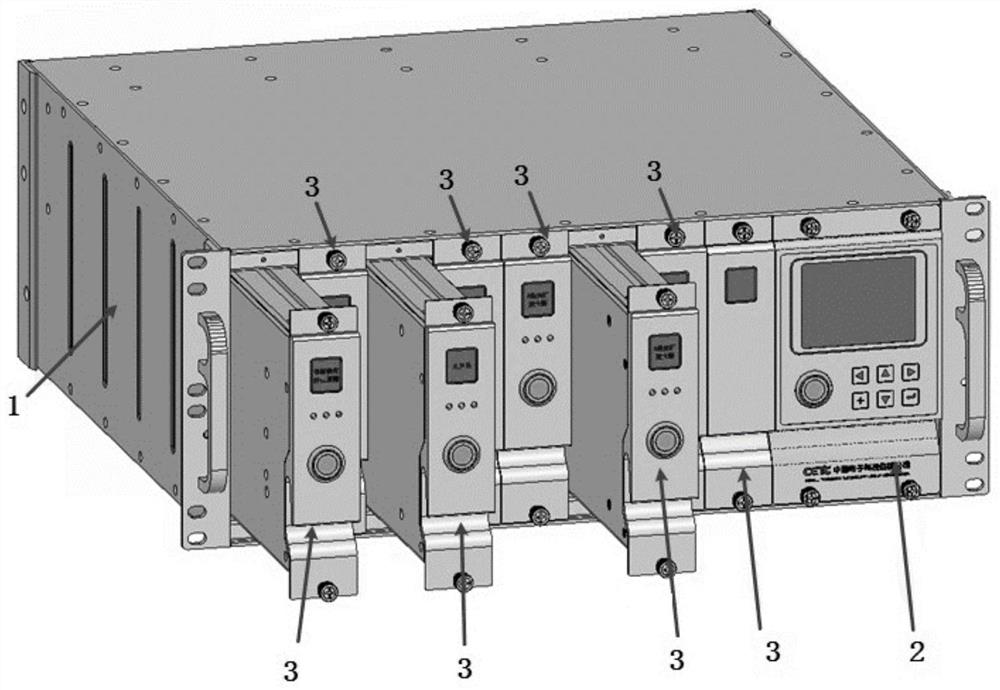

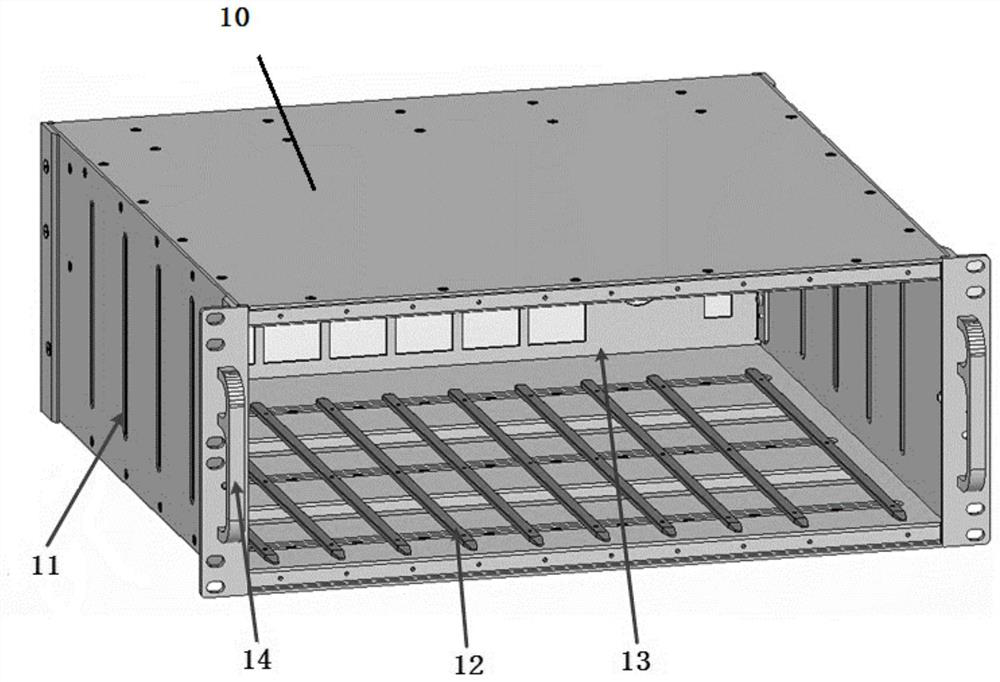

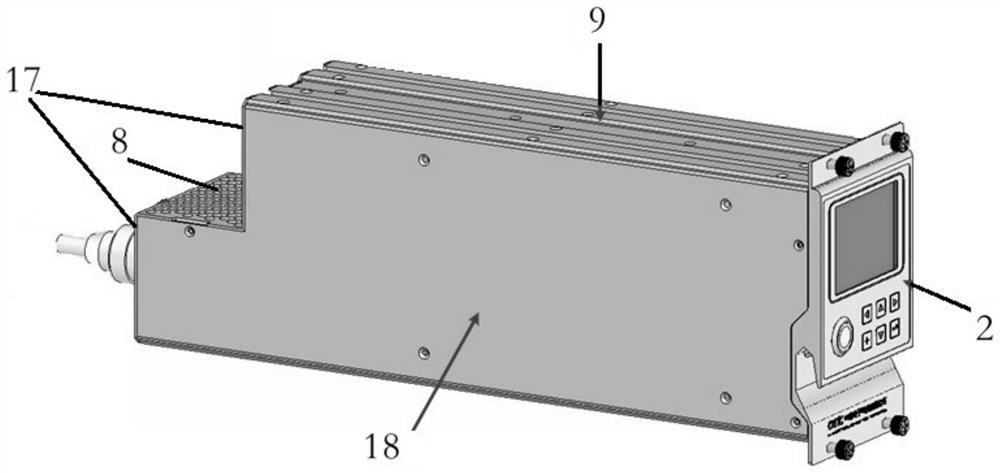

[0040] Subrack 1 in this embodiment adopts a 19-inch 4U chassis, and the front panel of the subrack is as follows: figure 1 The handle shown in the figure is convenient for moving, loading and unloading; the unified back wiring method is adopted to facilitate the unified wiring when installing and using on the rack. The structure of the subrack 1 adopts a modular design, and is composed of a subrack platform 1, a fan module 4, a power supply and control module 2, and 8 general-purpose plug-ins 3 . Among them, the plug-in 3 has a unified structure and interface design, and can be plugged and docked from any slot.

[0041] The plug-in box 1 adopts the "double-layer shielding structure design" in the electromagnetic field shielding structure, and the plug-in structure wrapped by a 2mm thick aluminum alloy forms an "inner shield", and a 4mm thick aluminum alloy metal plate is designed to form a box platform frame. shielding body. The double-layer shielding structure can enhance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com