Ball deep-frying device for food processing

A technology for food processing and meatballs, which is applied in the field of meatball frying devices for food processing, which can solve problems such as low efficiency, failure to filter oil residue, and uneven heating of oil, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

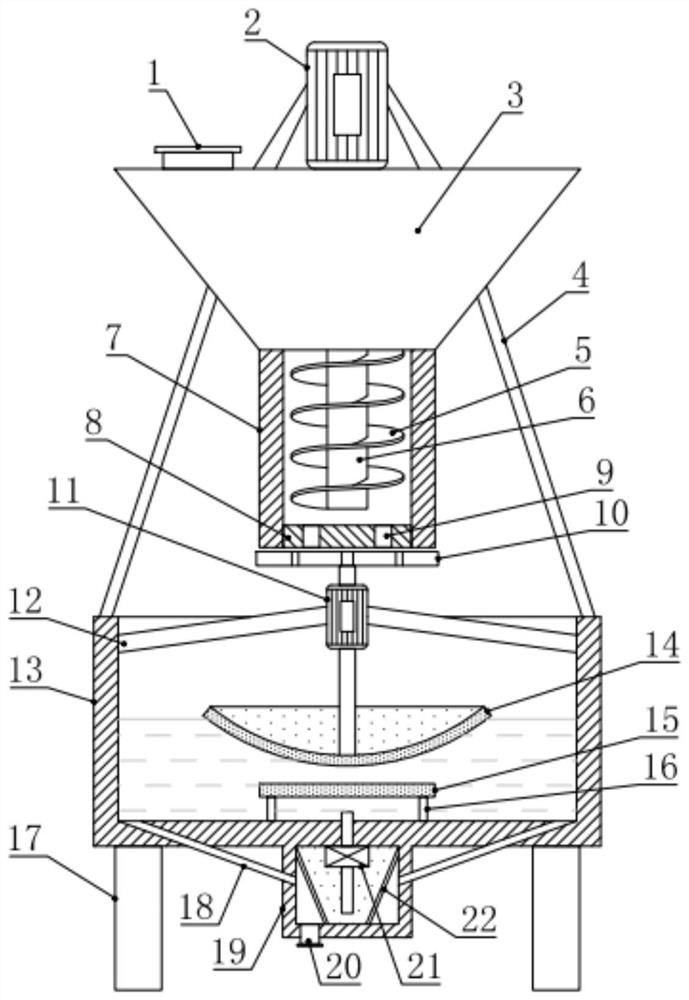

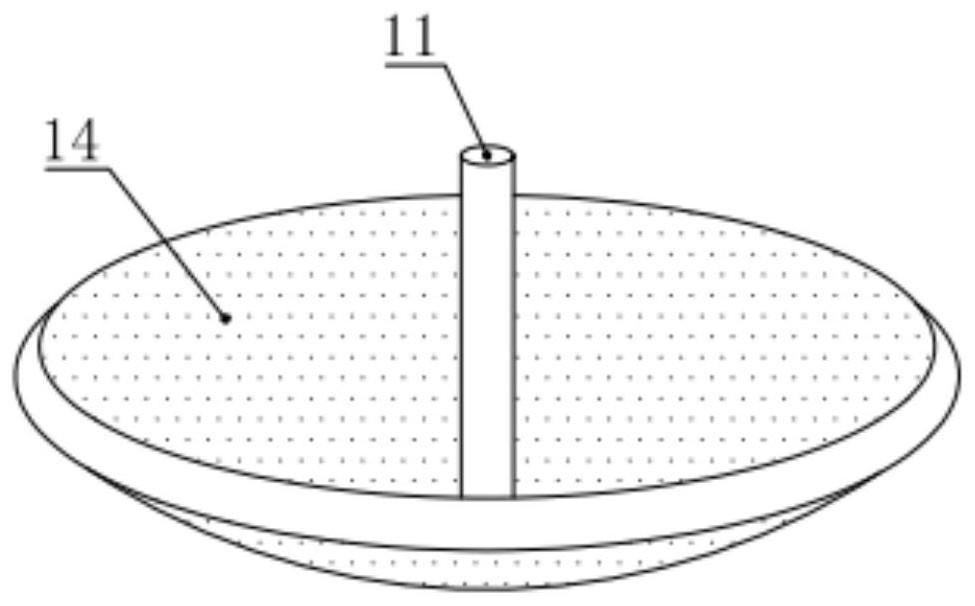

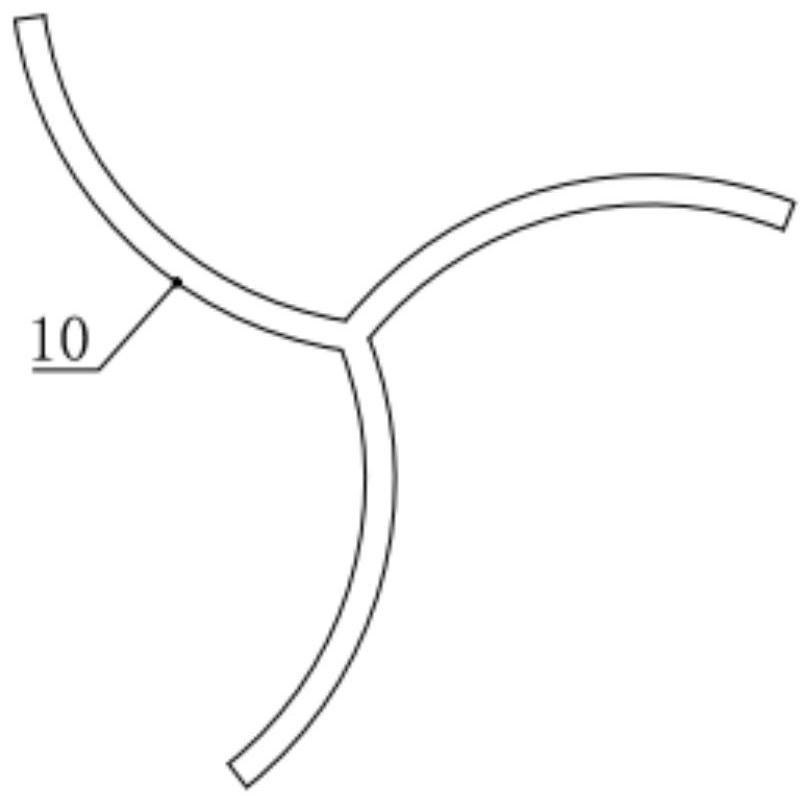

[0018] see figure 1 , in the embodiment of the present invention, a meatball frying device for food processing includes a material box 3 and a pot body 13, the material box 3 is fixed above the pot body 13, and a feeding tube 7 is installed at the lower end of the material box 3 The lower end of the feeding tube 7 is equipped with a ball extruding plate 8, and the feeding tube 7 is also equipped with a feeding assembly for extruding and conveying fillings to the ball extruding plate 8, and the ball extruding plate 8 The bottom is also fixed with a biaxial stretching motor 11, and the upper output shaft end of the biaxial stretching motor 11 is equipped with a scraper 10 for scraping off the filling material discharged from the ball extruding plate 8 to make pellets. The end of the output shaft on the lower side is installed with a centrifugal separation mesh plate 14 in the pot body 13, and a heating mesh plate 15 is installed and fixed on the inner bottom of the pot body 13, ...

Embodiment 2

[0021] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

[0022] In this embodiment, the outer circumferential distribution of the material box 3 is provided with a plurality of first diagonal struts 4, and the lower ends of the first diagonal struts 4 are fixed on the top of the pot body 13, through which the first diagonal struts 4 can For the stable support of the material box 3, the top of the material box 3 is also provided with a filling material adding port 1, through which the filling material adding port 1 is used for adding the filling material; the material delivery cylinder 7 is a vertically arranged cylindrical Cylinder body, the feeding assembly includes a feeding motor 2, a screw blade 5 and a feeding shaft 6, the feeding shaft 6 is arranged in the inner middle part of the feeding drum 7, and the feeding shaft 6 in the feeding drum 7 is also A screw blade 5 is installed, and the screw blade 5 is used to squeeze and convey the fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com