Vertical green walnut peeling machine

A technology of green walnut and peeling machine, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of unsatisfactory peeling effect of walnut machine, large difference in shape and size, different maturity, etc. The effect of wide width and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

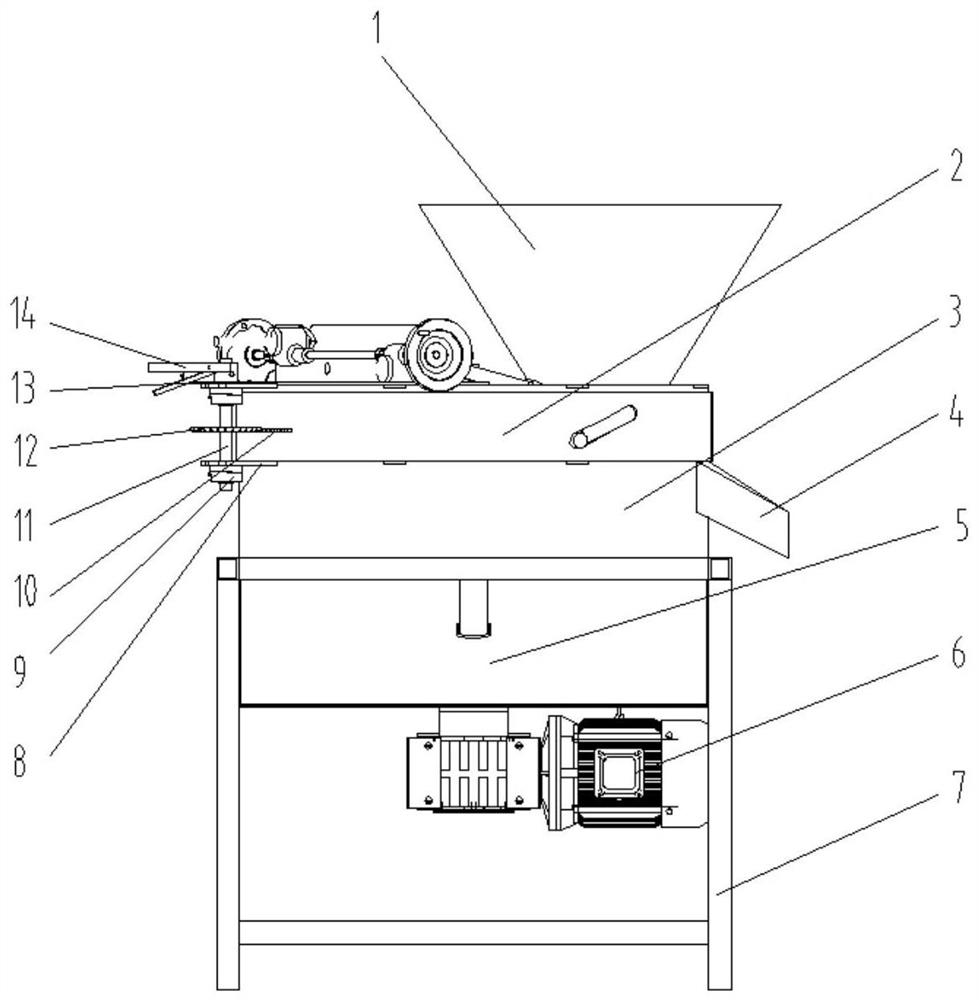

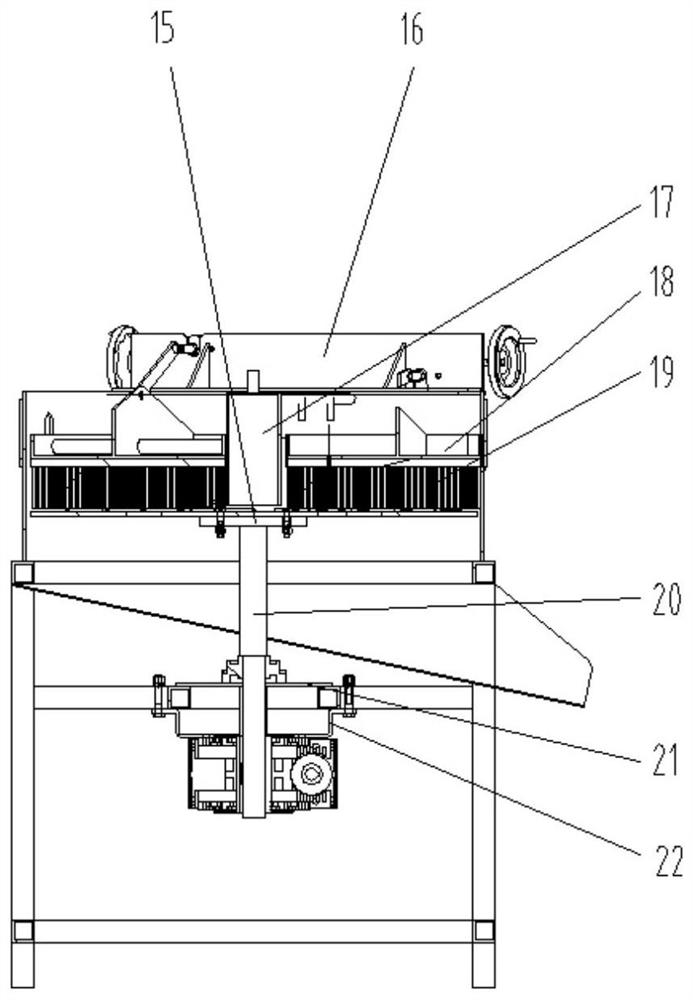

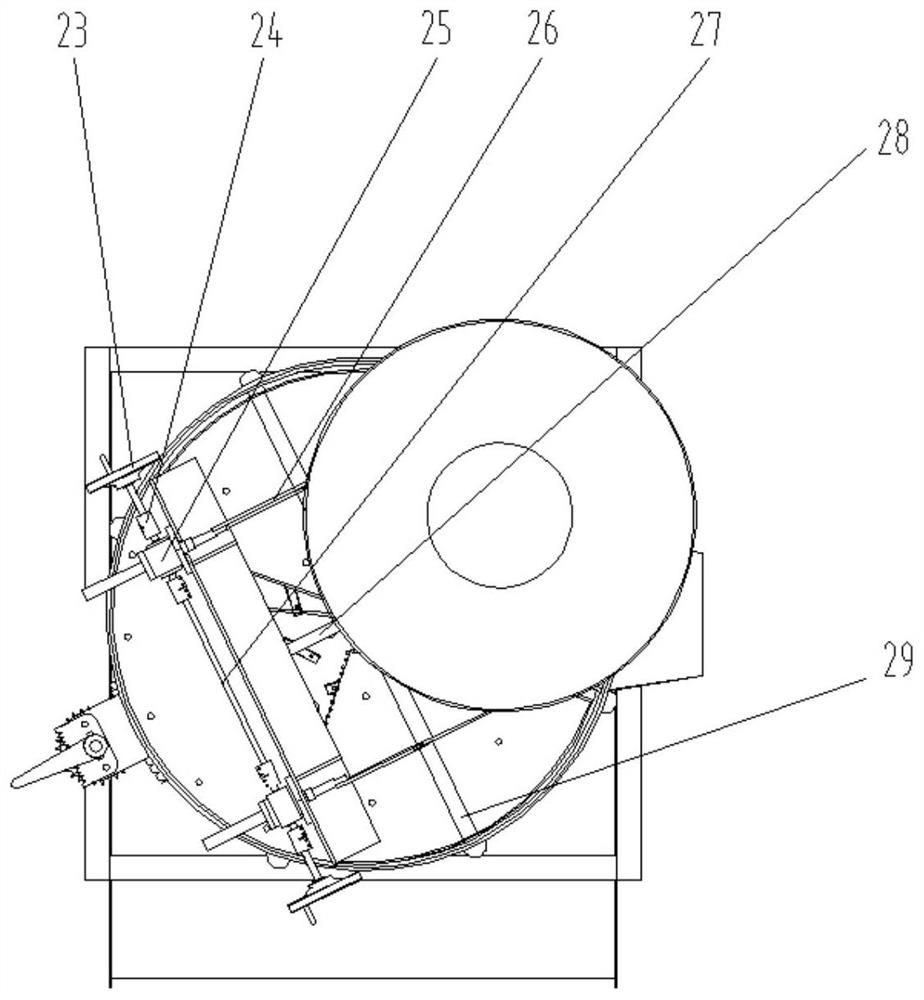

[0054] Frame 7 installs transmission shaft bearing mounting plate 21, bearing is fixed on the transmission shaft bearing mounting plate, transmission shaft 20 is fixed on the bearing, reducer fixing device 22 is arranged below the frame, is used for fixing motor reducer 6, power passes through The transmission shaft is passed to the flange 15, and the flange 15 is connected with the blade installation disk 33, and a U-shaped blade 34 is installed on the blade installation disk 33, and a group of U-shaped blades are arranged obliquely and parallel to the diameter line of the disk, forming an overall One is installed with some U-shaped blades and a circular turntable with elongated holes, a feed hopper 1 is arranged above the blade installation disk 33, a water spray pipe 28 and a distribution plate 32 are arranged at the feed hopper, and the distribution plate 32 is installed On the cloth installation plate 31, the water spray pipe is installed on the material blocking device 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com