Fan-shaped pipeline type ultrafine particle coagulator

A technology of ultra-fine particles and a condenser, which is used in the separation of dispersed particles, chemical instruments and methods, electrostatic effect separation, etc., can solve the problems of increasing the pressure drop of the condenser, affecting the flow rate of flue gas, and complex process equipment. To achieve the effect of reducing emissions, improving coagulation efficiency, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

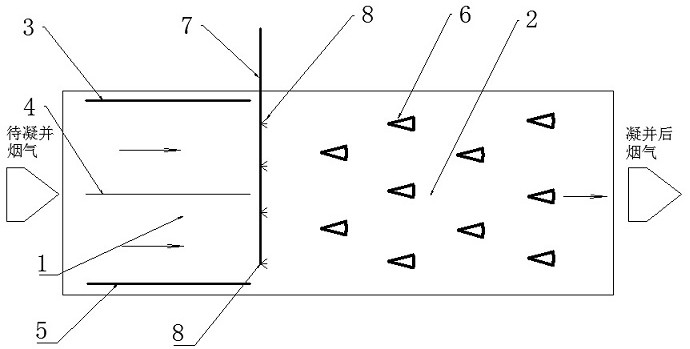

[0024] An industrial dust waste gas, the treatment capacity is 80000m 3 / h adopts fan-shaped pipe-type ultra-fine particle coalescer. The entire condenser is in the pipeline type, installed in the main dust collector - electrostatic precipitator, in the intake pipe before; the condenser is composed of a bipolar charging area and a condensation area; the bipolar charging area has a set of positive and negative Alternate parallel channels, with negative plates, positive plates and insulating plates for separation, the dust in the flue gas enters the condensation area after being charged; there are 4 sets of horizontal bars in the condensation area, the cross-sectional shape of the bars is It is fan-shaped; the condensed flue gas enters the main dust collector for processing.

[0025] The horizontal bars set in the condensation area are arranged up and down in each group, and the fan-shaped opening angle of the horizontal bars is 30 degrees; the height of the horizontal bars is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com