Vacuum mechanical automatic mixing equipment

A technology of mixing equipment and machinery, applied in mixers, mixer accessories, chemical instruments and methods, etc., can solve the problems of slow discharge, waste, and time-consuming, and achieve the effect of avoiding material residue, avoiding waste, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

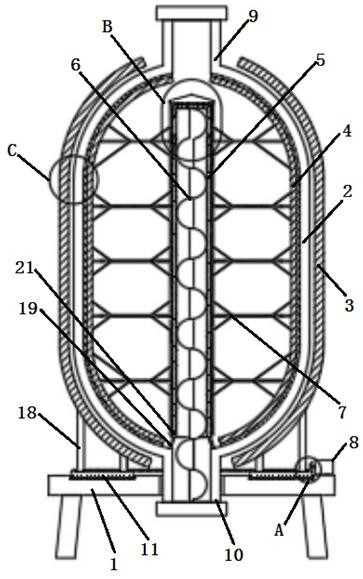

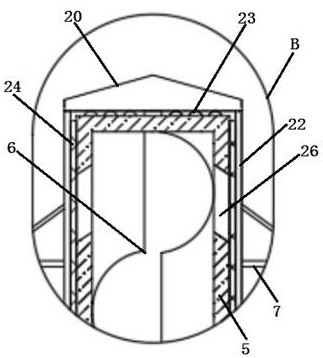

[0021] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , a vacuum mechanical automation mixing equipment provided by the present invention is now described, which includes a support platform 1 and a tank body 2 provided on the upper end of the support platform 1, and a first magnet is evenly arranged on the outer end wall of the tank body 2. Plate 3, close to the inner end wall of the tank body 2 and evenly provided with a second magnet plate 4, the middle side of the inner end of the tank body 2 is vertically provided with a lifting tube 5 and the lifting tube 5 is provided with a There is a lifter 6, a mixing support rod 7 is provided between the second magnet plate 4 and the material lifting pipe 5, and a driving motor 8 is provided at the upper end of the support table 1.

Embodiment 2

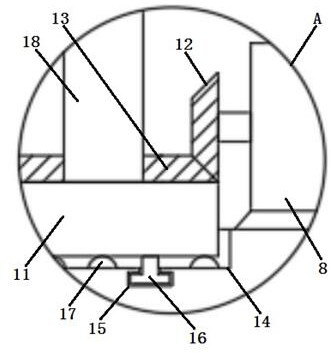

[0022] Example 2: see figure 1 , figure 2 , a kind of vacuum mechanical automatic mixing equipment provided by the present invention is now described, the top of the tank body 2 is equipped with a feeding pipe 9, and the bottom end is equipped with a discharge pipe 10, and the middle part of the upper end of the support table 1 has a circular opening, so The discharge pipe 10 is fixedly installed in the circular opening, the upper end of the support table 1 is provided with an annular seat 11, and the driving motor 8 is arranged on the side of the annular seat 11, and the output shaft of the driving motor 8 corresponds to The position of the ring seat 11 is set, the drive gear 12 is installed outside the output shaft of the drive motor 8, and the ring gear 13 is installed on the outer end wall of the ring seat 11 corresponding to the position of the drive gear 12. The drive gear 12 It is meshed with the ring gear 13 for transmission, and the end of the feed end of the feedin...

Embodiment 3

[0023] Embodiment 3: see figure 1 , figure 2 Now, a vacuum mechanical automation mixing equipment provided by the present invention will be described. The upper end of the support table 1 is provided with an annular rotating groove 14, and the annular seat 11 is movably placed in the rotating groove 14. The rotating groove 14 The inner bottom end is provided with an annular limiting groove 15, and the lower end of the annular seat 11 is evenly provided with a limiting rotating rod 16, and a first The ball 17, the first magnet plate 3 is installed on the upper end of the ring seat 11 through the support column 18.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap