After-rolling controlled cooling method for spring steel wire rod

A technology of steel wire rod and spring steel, which is applied in metal rolling, temperature control, metal rolling, etc., can solve the problems of poor performance of the same coil, etc. The effect of carbon layer depth improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

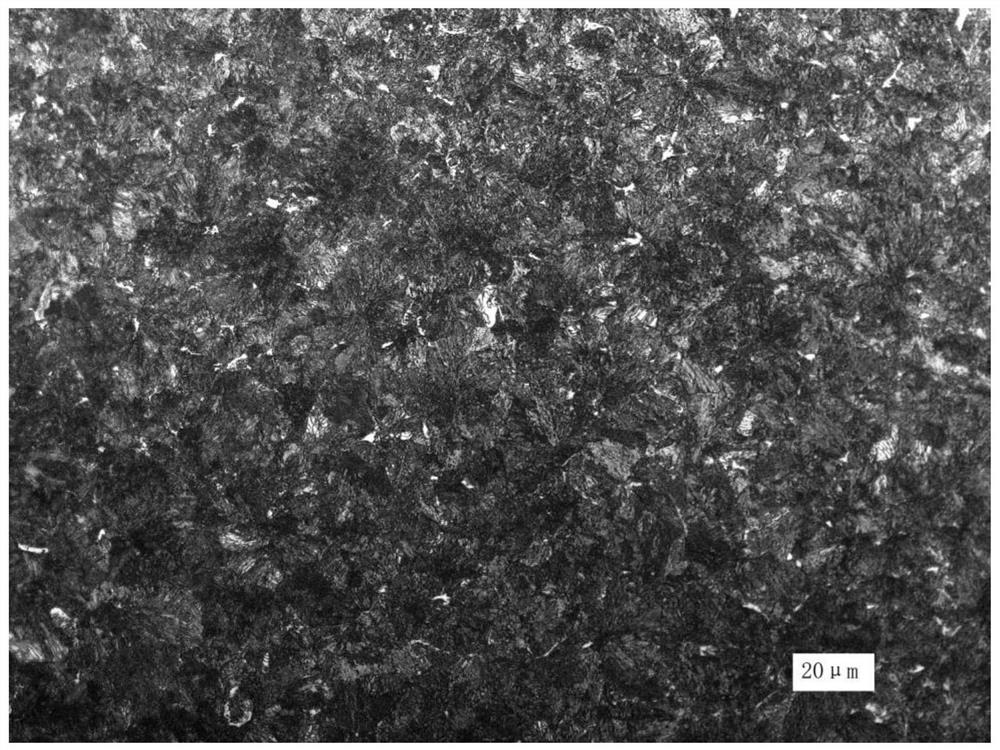

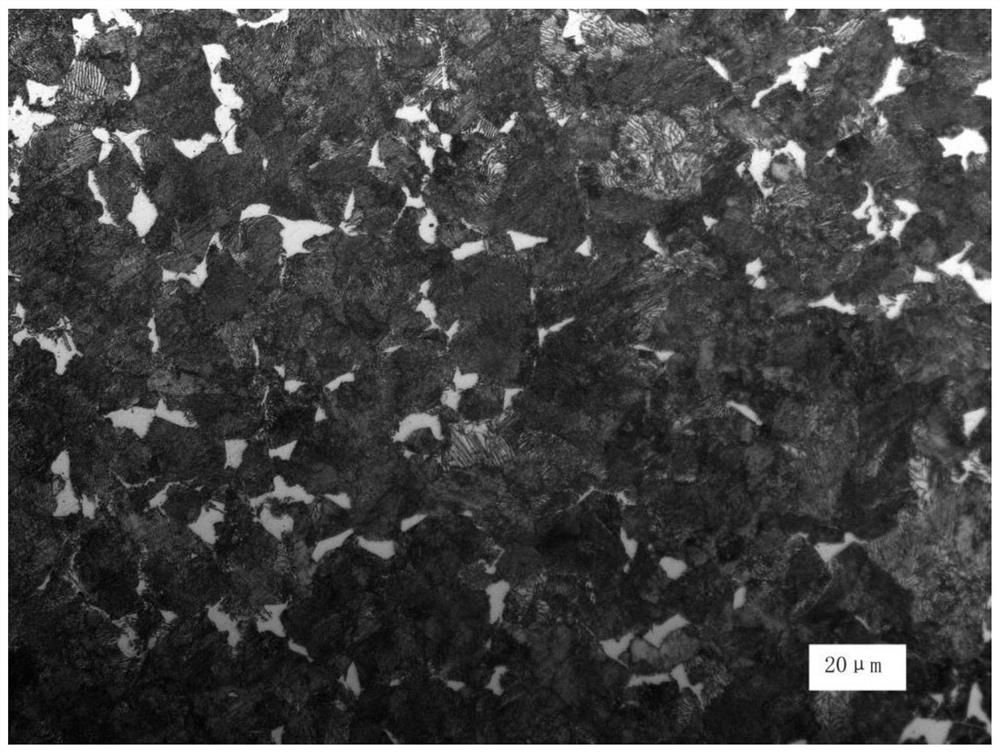

Image

Examples

Embodiment 1

[0035] In this embodiment, the spring steel grade is 55SiCr, and the diameter specification is After the wire rod is rolled, the cooling is controlled according to the following parameters: wire rod spinning temperature: 860°C; wire rod temperature when entering the EDC water tank: 820°C; water bath temperature: 95°C; wire rod outlet water temperature: 560°C; water tank The pressure of compressed air flowing into the bottom: 0.5MPa.

[0036] The tensile strength of the steel spring steel wire rod produced in this embodiment is 1000~1150MPa, the reduction of area ≥ 40%, the poor performance of the same coil is below 60MPa, the structure is uniform and there is no low temperature structure such as martensite and bainite, and the wire rod is detached. The carbon layer is less than 60 microns and uniformly controlled, which satisfies the user's technical requirements for spring steel wire rods.

Embodiment 2

[0038] In this embodiment, the spring steel grade is 55SiCr, and the diameter specification is After the wire rod is rolled, the cooling is controlled according to the following parameters: wire rod spinning temperature: 850°C; wire rod temperature when entering the EDC water tank: 810°C; water bath temperature: 96°C; wire rod outlet water temperature: 570°C; water tank The pressure of compressed air flowing into the bottom: 0.8MPa.

[0039] The tensile strength of the spring steel wire rod produced in this embodiment is 1000-1150 MPa, the reduction of area is ≥ 40%, the performance difference of the same ring is less than 60 MPa, the structure is uniform and there is no low-temperature structure such as martensite and bainite, and the wire rod is decarburized The layer is less than 60 microns and uniformly controlled, which satisfies the user's technical requirements for spring steel wire rods.

Embodiment 3

[0041] In this embodiment, the spring steel grade is 55SiCr, and the diameter specification is After the wire rod is rolled, the cooling is controlled according to the following parameters: wire rod spinning temperature: 840°C; wire rod temperature when entering the EDC water tank: 820°C; water bath temperature: 100°C; wire rod outlet water temperature: 580°C; water tank The pressure of compressed air flowing into the bottom: 1.0MPa.

[0042] The tensile strength of the spring steel wire rod produced in this embodiment is 1050-1150 MPa, the reduction of area is ≥ 40%, the performance difference of the same coil is less than 60 MPa, the structure is uniform and there is no low-temperature structure such as martensite and bainite, and the wire rod is decarburized The layer is less than 70 microns and uniformly controlled, which satisfies the technical requirements of users for spring steel wire rods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com