Hoisting inclined wedge with detachable stop block

A technology of stoppers and wedges, applied in forming tools, manufacturing tools, transportation and packaging, etc., can solve the problems of error accumulation, small mounting surface of the pressing end of the slider, and large height of the driving components, so as to improve the impact resistance Excellent ability, high guiding precision and large sliding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

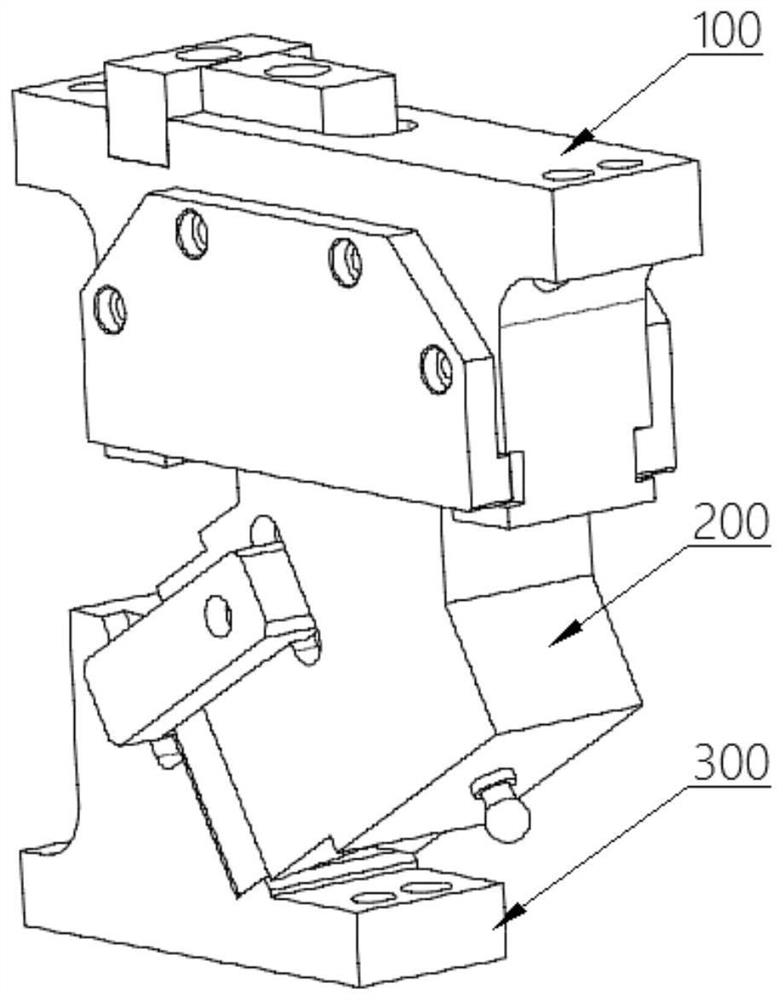

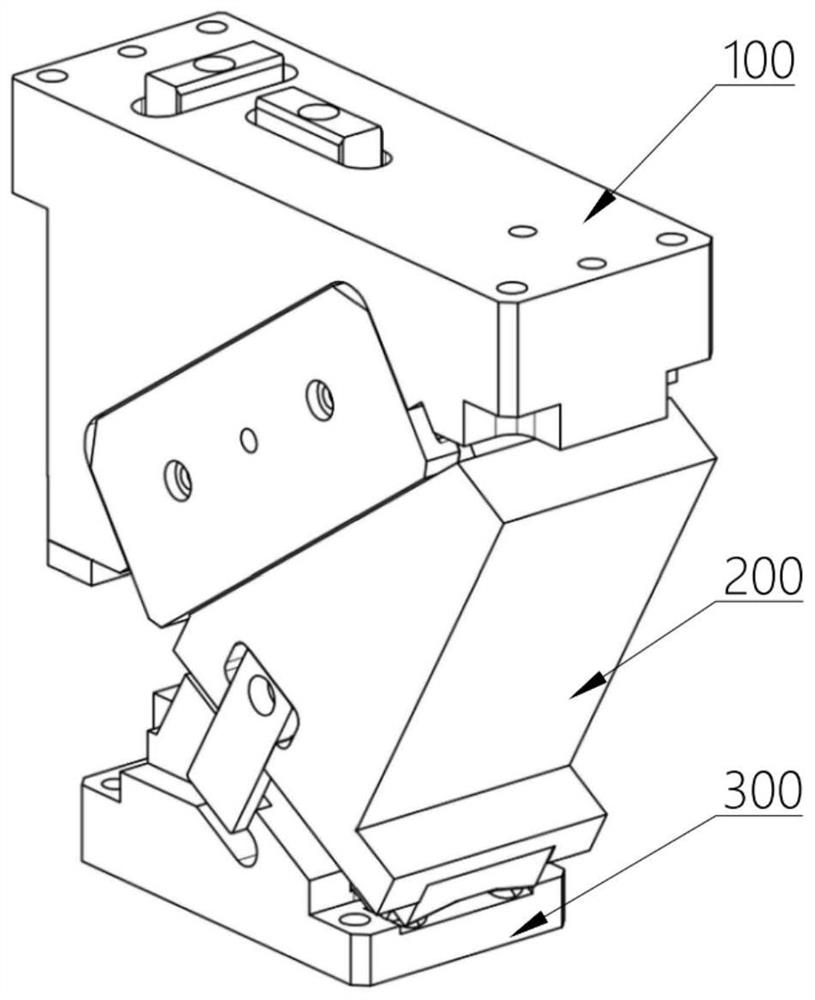

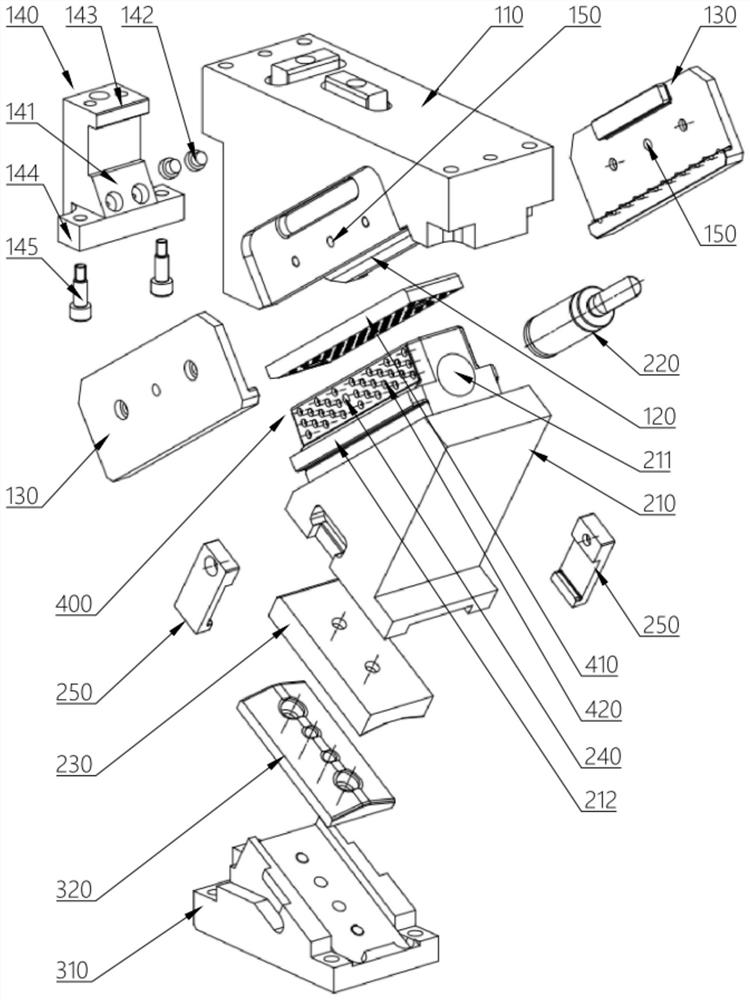

[0038] Such as Figure 2-6 As shown, this embodiment discloses a lifting wedge with a working face width of 100 mm and a hanging platform stop block. The lifting wedge includes a base assembly 100 , a slider assembly 200 and a drive assembly 300 . in:

[0039] The base assembly 100 includes a base 110 and a limiting side plate 130. The base 110 is provided with a chute 120, one end of the chute 120 is closed, the other end is set to be open, and a stop block 140 is detachably provided at the open end. . A rubber buffer 142 is provided on the side of the stop block 140 facing the sliding groove 120 for buffering the retracted slider 210 .

[0040]The slider assembly 200 includes a slider 210 , a spring 220 (using a nitrogen gas spring), a first V-shaped guide plate 230 and a forced returner 250 . The top of slide block 210 is installed in the chute 120 of base 110 , and one end of spring 220 is fixed in the slide block hole 211 of slide block 210 upper end with screw, and t...

Embodiment 2

[0050] Such as Figure 7-9 As shown, this embodiment discloses a lifting wedge with a working face width of 100 mm and a boss-type stop block.

[0051] The angle between the bottom surface of the wedge chute and the horizontal direction is less than 45 degrees, so the boss type stop block is adopted, and the protruding direction of the stop boss 143 is vertically upward. Meanwhile, the upper ends of both sides of the nut seat 144 are also provided with The vertically upward bosses and the upper and lower bosses are respectively connected with the vertically downward opening grooves on the base 110 to form a horizontal limit, which greatly improves the bearing strength in the horizontal direction.

[0052] All the other are identical with embodiment 1.

Embodiment 3

[0054] Such as Figure 10-12 As shown, this embodiment discloses a lifting wedge with a working surface width of 350 mm and a hanging platform stop block.

[0055] Due to the large width of the working face, in order to ensure the stability of lateral guide sliding, this embodiment has made the following improvements on the basis of embodiment 1:

[0056] 1) The guide-sliding structure 400 includes four guide plates 410 and a guide key 430. Two parallel guide plates 410 are used between the top of the slider 210 and the bottom surface of the chute 120 to guide the slide. Guide key 430 to improve guide accuracy. The guide key 430 is installed on the keyway at the bottom of the chute 120 with screws, and is matched with the keyway at the top of the slider 210. The guide key has not only increased the guiding accuracy, but also increased the ability of the wedge to bear lateral force; at the same time, the slide Both sides of the block are also provided with guide plates 410, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com