Quantitative analysis method for heavy metals indesulfurized sludge based on electrokinetic treatment

A technology for quantitative analysis and desulfurization sludge, which is applied in thermal excitation analysis, material excitation analysis, dehydration/drying/thickened sludge treatment, etc., can solve the problem of rarely researched pretreatment agent synergistic electrokinetic method, research, current and pH value Changes in the study of less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

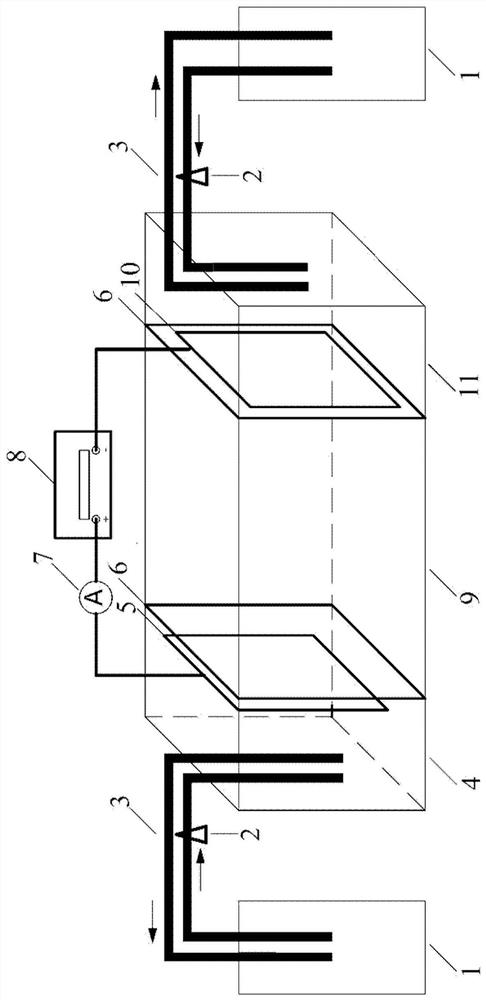

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

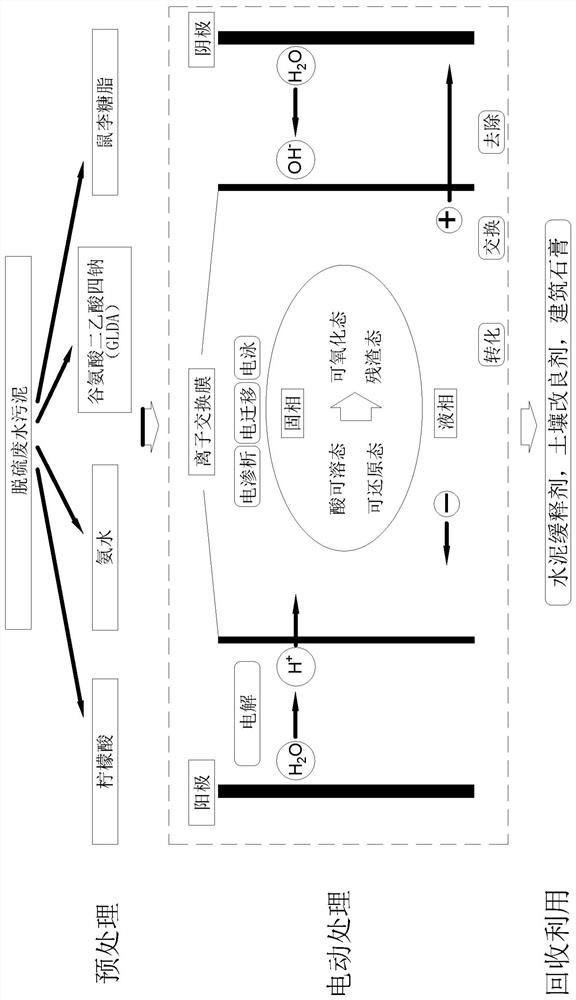

[0017] The invention discloses a quantitative analysis method for treating heavy metals in desulfurization sludge based on electrokinetic reaction, including:

[0018] According to the total amount of heavy metal elements N in the desulfurization sludge before and after electrokinetic reaction treatment and the amount of various forms of heavy metal elements N, the conversion potential TP of heavy metal elements N before and after the electrokinetic reaction treatment was calculated. N , exchange potential EP N and depotential RP N ;

[0019] According to the obtained conversion potential, exchange potential and removal potential, the electrokinetic reaction process is analyzed.

[0020] In some embodiments of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com