Preparation method for pH and temperature dual-sensitive ion micro-hydrogel

A dual-sensitive, ionic technology, applied in the field of environment-sensitive polymer materials, can solve the problems of long purification process, cumbersome preparation method, wide particle size distribution, etc., and achieve clear reaction process, simple preparation method and convenient purification process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

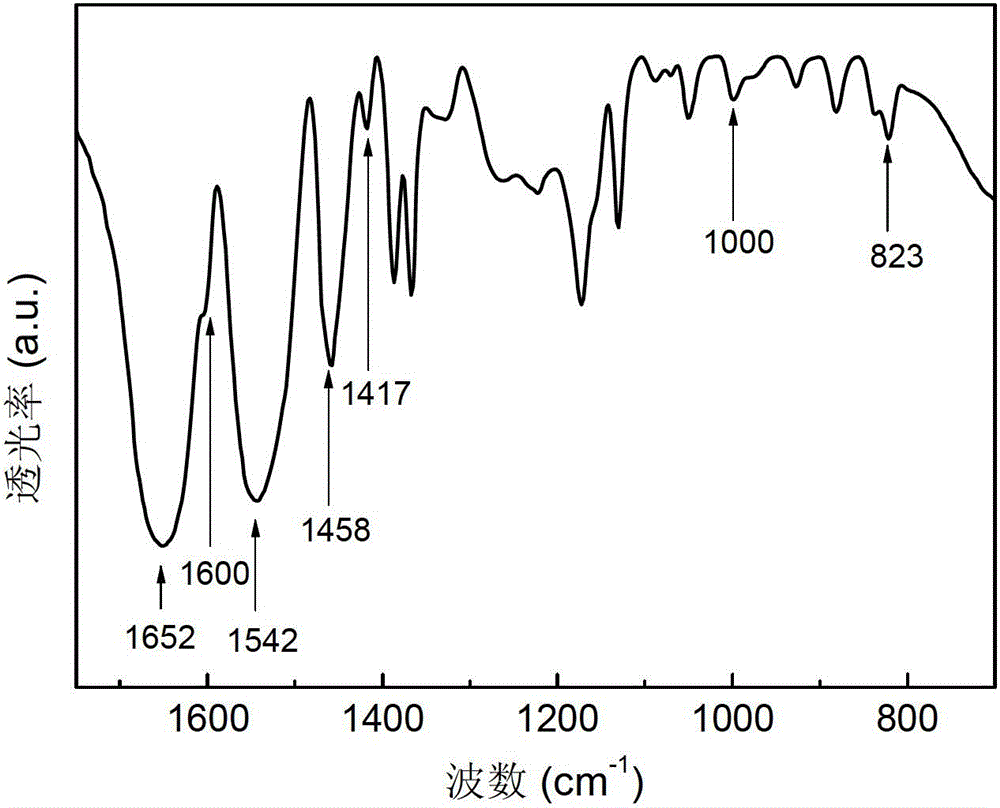

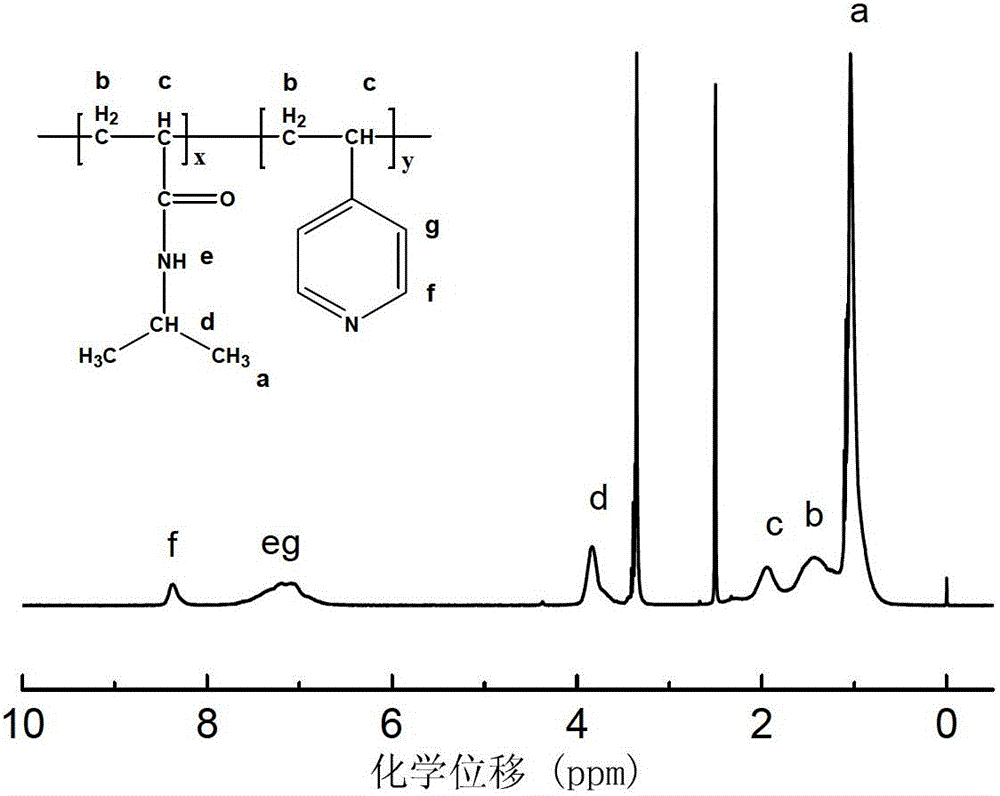

[0035] 1.5g temperature-sensitive monomer N-isopropylacrylamide (NIPAm), 0.09g pH-sensitive monomer 4-vinylpyridine (4VP) were dissolved in anhydrous 1, 4-dioxane, under nitrogen atmosphere Stir under the conditions to make it fully dissolve, then add 0.036g of azobisisobutyronitrile, stir fully, and react at a constant temperature in a 70°C oil bath for 24 hours under a nitrogen atmosphere, then take it out and cool it to room temperature naturally; The reactant is precipitated out, and vacuum-dried after centrifugation for 15 minutes at 4000 rpm to obtain a binary copolymer P (NIPAm-co-4VP), with a weight-average molecular weight of 35000. The infrared spectrogram of the copolymer is shown in figure 1 (1652cm -1 、1542cm -1 、1458cm -1 The characteristic absorption bands in N-isopropylacrylamide are assigned to the -C=O stretching vibration peak, -N-H bending vibration peak and -CH 3 The asymmetric bending vibration peak; 1600cm -1 、1415cm -1 、1000cm -1 and 823cm -1 The...

Embodiment 2

[0042] 1.5g temperature-sensitive monomer N-isopropylacrylamide (NIPAm), 0.09g pH-sensitive monomer 4-vinylpyridine (4VP) were dissolved in anhydrous 1, 4-dioxane, under nitrogen atmosphere Stir under the conditions to make it fully dissolve, then add 0.036g of azobisisobutyronitrile, stir fully, and react at a constant temperature in a 70°C oil bath for 24 hours under a nitrogen atmosphere, then take it out and cool it to room temperature naturally; The reactant is precipitated out, and vacuum-dried after centrifugation for 15 minutes at 4000 rpm to obtain binary copolymer P (NIPAm-co-4VP), with a weight-average molecular weight of 35000; the above-mentioned copolymer is dissolved in deionized water, and then separately treated as follows:

[0043] (1) Make an aqueous solution with a mass concentration of 0.05%, stir to make it fully dissolve, heat up to 50°C, add 1,3-dichloropropane to cause quaternization reaction of all pyridine, stir at constant temperature for 24 hours, ...

Embodiment 3

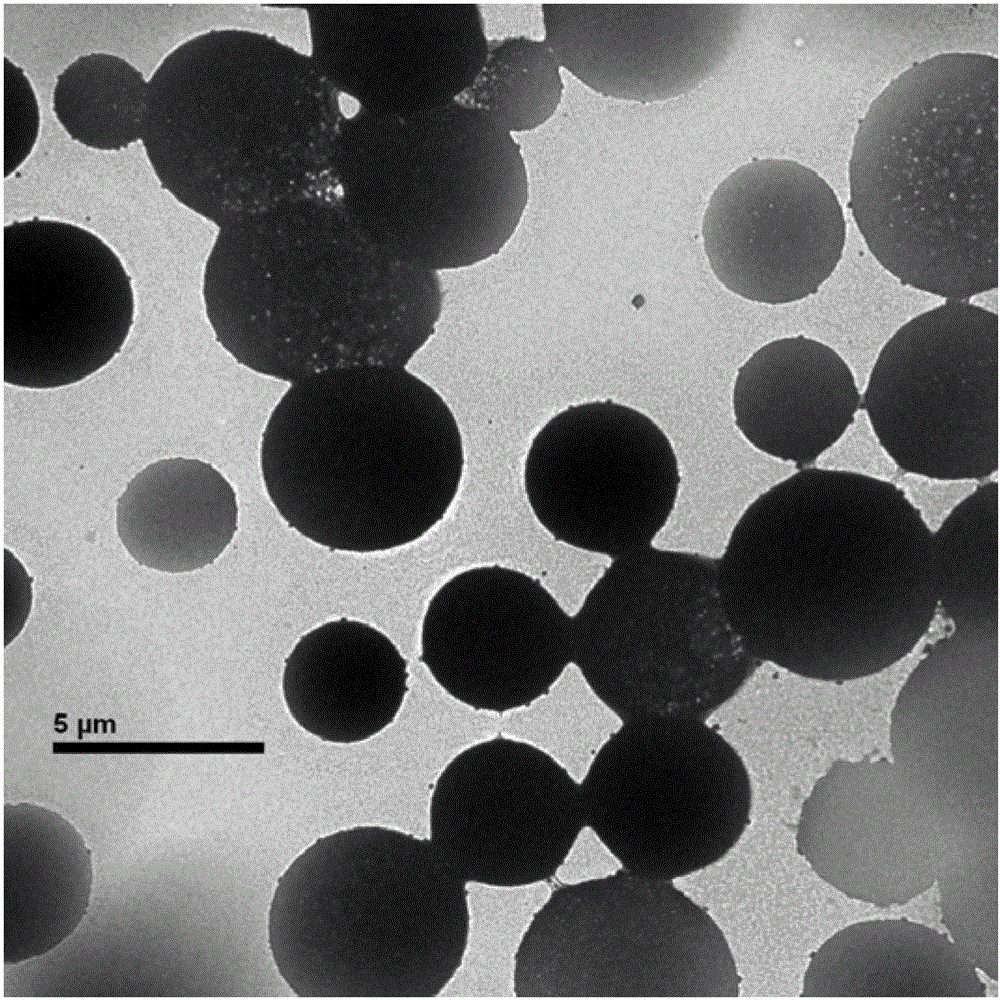

[0050] 1.5g temperature-sensitive monomer N-isopropylacrylamide (NIPAm), 0.09g pH-sensitive monomer 4-vinylpyridine (4VP) were dissolved in anhydrous 1, 4-dioxane, under nitrogen atmosphere Stir under the conditions to make it fully dissolve, then add 0.036g of azobisisobutyronitrile, stir fully, and react at a constant temperature in a 70°C oil bath for 24 hours under a nitrogen atmosphere, then take it out and cool it to room temperature naturally; The reactant is precipitated out, and vacuum-dried after centrifugation for 15 minutes at 4000 rpm to obtain binary copolymer P (NIPAm-co-4VP), with a weight-average molecular weight of 35000; the above-mentioned copolymer is dissolved in In deionized water, the mass concentration is 0.3%, stir to make it fully dissolved, heat up to 50 ° C, add 1, 4-dibromobutane to make 1 / 3 pyridine undergo quaternization reaction, stir at constant temperature for 24 hours, at 13000 rpm Centrifuge for 30 minutes per minute, add deionized water to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com