Preparation method of micro-hydrogel having high selective detection activity to heavy metal lead

A high-selectivity, heavy metal technology, applied in the direction of measuring devices, instruments, analytical materials, etc., can solve the problems of unfavorable industrial production scientific research, complicated preparation and detection methods, and unobvious detection selectivity, so as to increase the characteristics of polyionic liquids , high selective detection performance, simple and controllable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

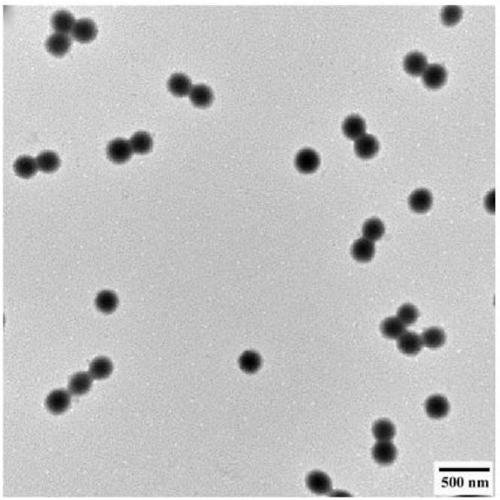

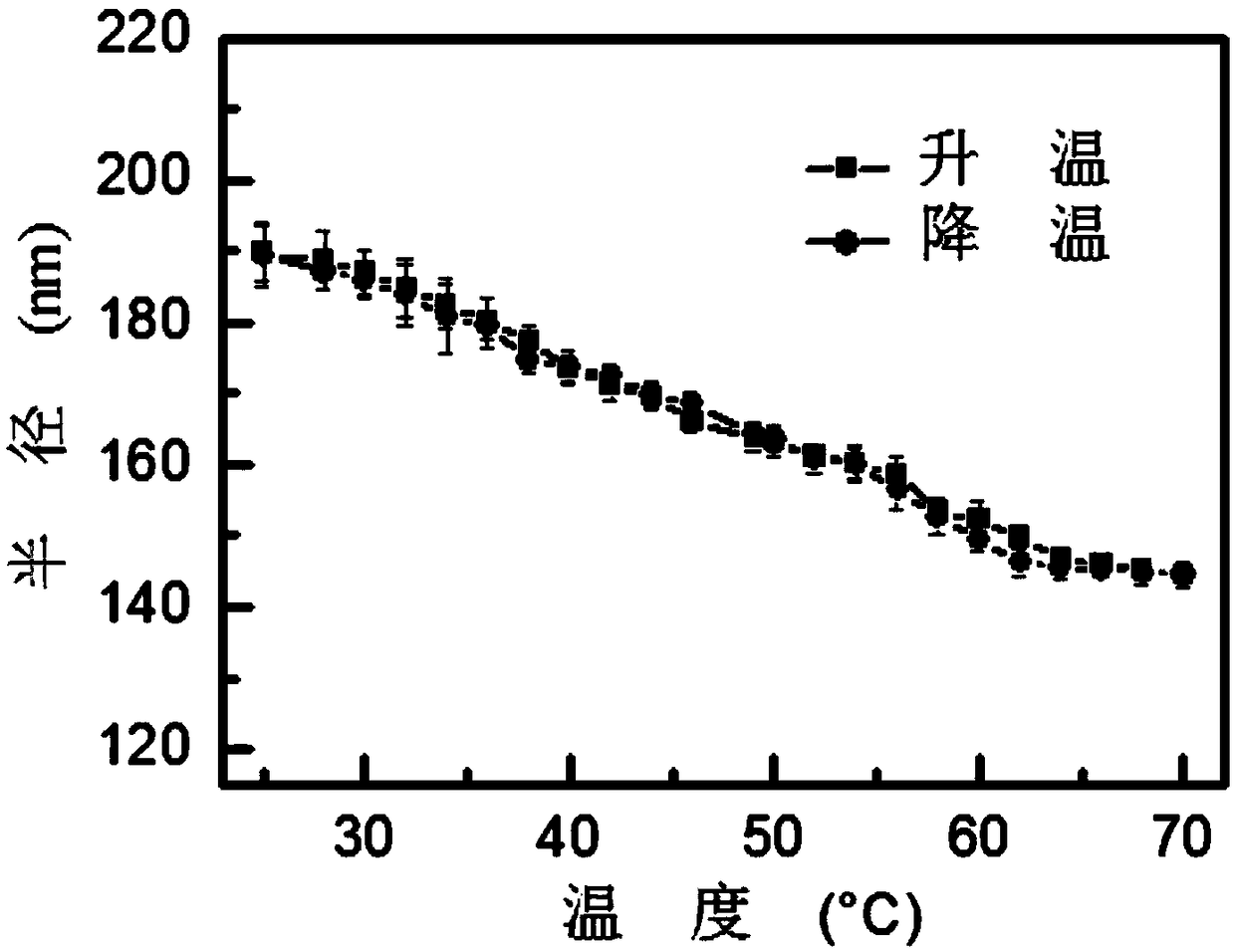

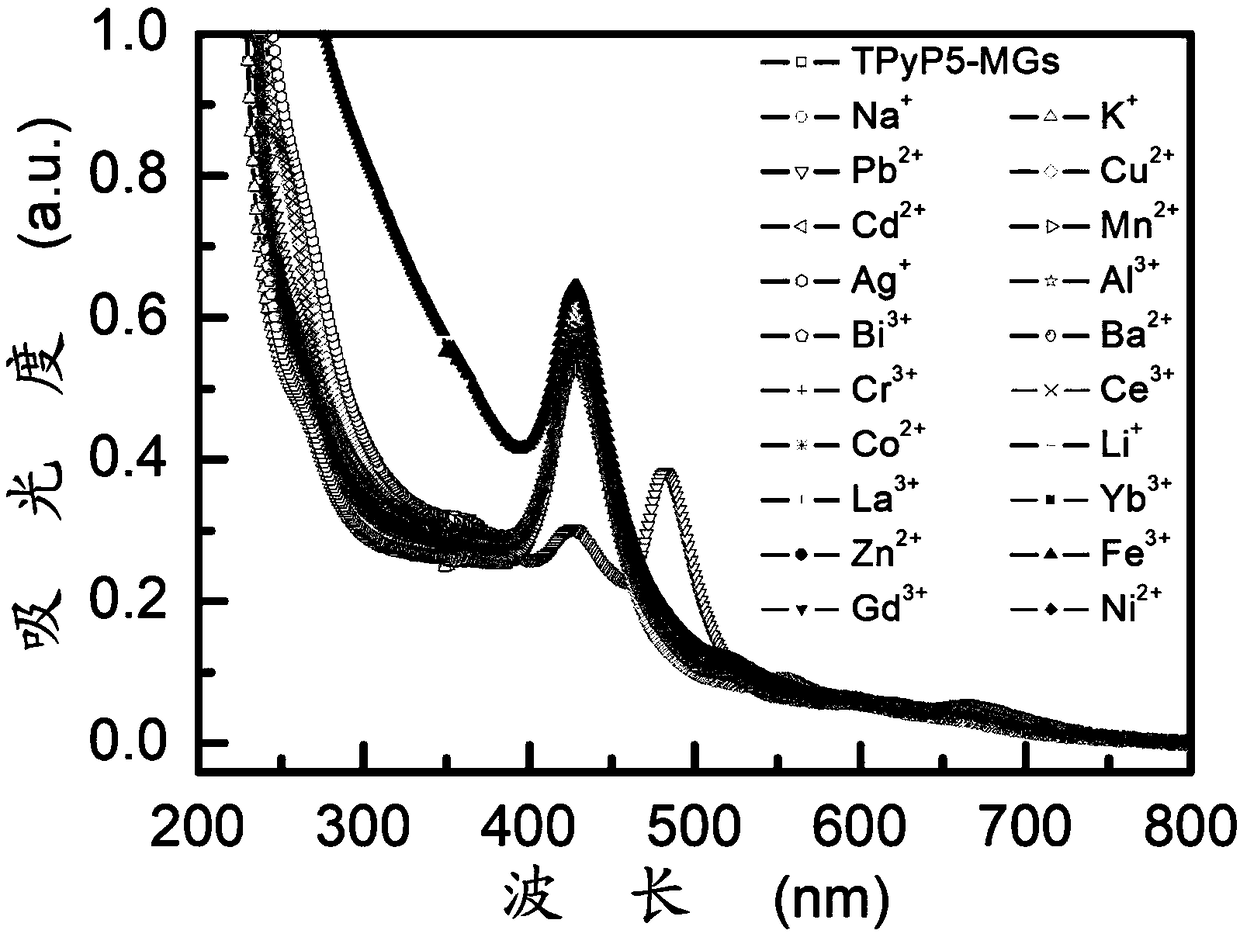

[0042] 0.021g functional monomer 5,10,15,20-(4-pyridyl)porphyrin (TPyP) and 0.086g dihaloalkane 1,5-dibromopentane dissolved in organic solvent N,N-dimethylformamide (DMF) solution, stirred to fully dissolve, reacted at 70° C. for 12 hours, and cooled to room temperature after the reaction.

[0043]0.23g temperature-sensitive monomer N-isopropylacrylamide (NIPAm) and 0.047g tertiary ammonium group-containing monomer N-vinylimidazole (VIM) were dissolved in deionized water, stirred under nitrogen atmosphere to make it fully Dissolve, then add 0.034g of initiator 2,2'-azobisisobutylamidine dihydrochloride, stir well, under nitrogen atmosphere, react at constant temperature in 70°C oil bath for 20 minutes, then add the previously prepared N, N-dimethylformamide solution (reaction product containing 5,10,15,20-(4 pyridyl) porphyrin and dihaloalkane), continued to react for 6 hours, followed by N, N-dimethyl After formamide and deionized water dialysis and purification for one wee...

Embodiment 2

[0047] 0.021g functional monomer 5,10,15,20-(4-pyridyl)porphyrin (TPyP) and 0.086g dihaloalkane 1,4-dibromobutane dissolved in organic solvent N,N-dimethylformamide (DMF) solution, stirred to fully dissolve, reacted at 130° C. for 72 hours, and cooled to room temperature after the reaction.

[0048] 0.34g temperature-sensitive monomer N-isopropylacrylamide (NIPAm) and 0.0021g tertiary ammonium group-containing monomer 4-vinylpyridine (4-VP) were dissolved in deionized water and stirred under nitrogen atmosphere It is fully dissolved, and then add 0.034g initiator 2,2'-azobisisobutylamidine dihydrochloride, stir well, and react at a constant temperature of 60°C in an oil bath for 20 minutes under nitrogen atmosphere, before adding Prepared N,N-dimethylformamide solution (reaction product containing 5,10,15,20-(4 pyridyl)porphyrin and dihaloalkane), continued to react for 6 hours, followed by N,N-di After methylformamide and deionized water dialysis and purification for one wee...

Embodiment 3

[0051] 0.005g functional monomer 5,10,15,20-(4-pyridyl)porphyrin (TPyP) and 0.012g dihaloalkane 1,3-dibromopropane were dissolved in organic solvent N,N-dimethylformamide ( DMF) solution, stirred to fully dissolve, reacted at 100°C for 24 hours, and cooled to room temperature after the reaction.

[0052] 0.23g temperature-sensitive monomer N-isopropylacrylamide (NIPAm) and 0.05g tertiary ammonium group-containing monomer N-vinylimidazole (VIM) were dissolved in deionized water, stirred under nitrogen atmosphere to make it fully Dissolve, then add 0.012g of initiator 2,2'-azobisisobutylamidine dihydrochloride, stir well, under nitrogen atmosphere, react at constant temperature in an oil bath at 80°C for 20 minutes, then add the previously prepared N, N-dimethylformamide solution (reaction product containing 5,10,15,20-(4 pyridyl) porphyrin and dihaloalkane), continued to react for 6 hours, followed by N, N-dimethyl After formamide and deionized water dialysis and purification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com