Lutein water-soluble powder and preparation process thereof

A technology of water-soluble powder and lutein, which is applied in the field of medicine, can solve the problems of inability to guarantee the melting of lutein crystals, high requirements for operating conditions, and unstable properties of lutein, so as to achieve good water solubility and expand the scope of application , good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

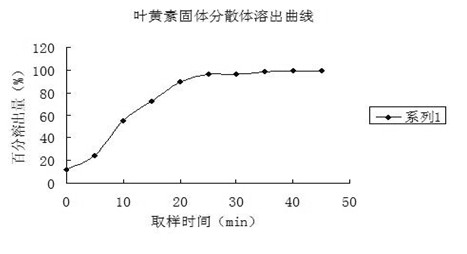

Image

Examples

Embodiment 1

[0037] Take 5 g of high-purity lutein crystals, 5 g of povidone K90, 2.5 g of Tween 70, and 50 ml of acetone, stir for 5 minutes, fully dissolve, and evaporate to dryness in a normal-pressure water bath at 60°C. After being embrittled, take it out and crush it through an 80-mesh sieve.

Embodiment 2

[0039] Take 10g of 80% lutein, 20g of polyethylene glycol 2000, 10g of Tween 65, and 60ml of ethyl acetate, stir for 10 minutes and fully dissolve, and evaporate to dryness in a water bath with a vacuum of 0.7 MPa at 30°C. After being embrittled, take it out and crush it through an 80-mesh sieve.

Embodiment 3

[0041]Take 15g of 70% lutein, 45g of povidone K29, 10g of fatty acid sucrose ester SE15, and 100ml of absolute ethanol, stir for 20 minutes and fully dissolve, and evaporate to dryness in a water bath with a vacuum of 0.9 MPa at 35°C. After being embrittled, take it out and crush it through an 80-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com