Method for separating and purifying L-leucine

A technology for separation and purification of leucine, applied in chemical instruments and methods, organic chemistry, cyanide reaction preparation, etc., can solve the problem of not separating L-leucine and L-valine, reducing L-leucine Acid yield and other issues, to avoid excessive losses, increase difficulty, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

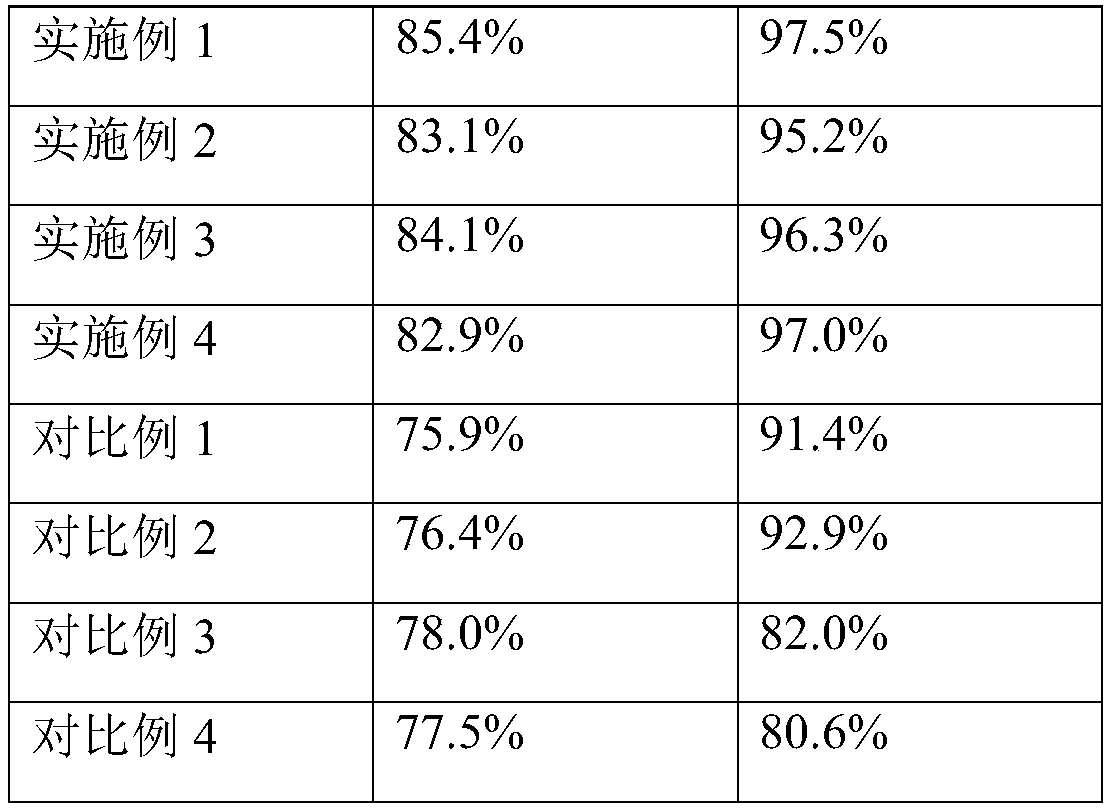

Embodiment 1

[0029] Embodiment 1 A kind of separation and purification method of L-leucine

[0030] (1) add 20g polyaluminum iron and 30mg chitosan to every liter of fermentation broth, let stand, and centrifuge to obtain supernatant for later use;

[0031] (2) The pH value of the supernatant was adjusted to 1.5, sodium chloride was added to make the sodium chloride concentration reach 0.25g / ml, then L-leucine seed crystals were added, and the precipitate was separated by standing at 4°C for 24 hours;

[0032] (3) Add 15 times of water at 85°C to dissolve the precipitate, add 4% of the solution volume of activated carbon to decolorize for 1 hour, after centrifugation, adjust the pH of the supernatant to 5.5, concentrate to 1 / 10 of the original volume, let stand, and precipitate out crystal;

[0033] (4) The crystals were dissolved in water, passed through 007×7 strong cation exchange resin chromatography, eluted with 1 mol / L ammonia water, and the flow rate was controlled to be 2 ml / min. ...

Embodiment 2

[0034] Embodiment 2 A kind of separation and purification method of L-leucine

[0035] (1) add 15g zinc sulfate and 40mg diatomaceous earth in every liter of fermented liquid, let stand, centrifuge to obtain supernatant for subsequent use;

[0036] (2) The pH value of the supernatant was adjusted to 1.0, and sodium chloride was added to make the sodium chloride concentration reach 0.20 g / ml, then L-leucine seed crystals were added, and the precipitate was separated by standing at 4°C for 24 hours;

[0037] (3) Add 10 times water at 90°C to dissolve the precipitate, add 2% of the solution volume of activated carbon to decolorize for 1 hour, and after centrifugation, adjust the pH of the supernatant to 5.0, concentrate to 1 / 8 of the original volume, let stand, and precipitate out crystal;

[0038] (4) The crystals were dissolved in water, chromatographed through D001 cation exchange resin, eluted with 0.5 mol / L ammonia water, and the flow rate was controlled to be 1 ml / min. The...

Embodiment 3

[0039] Embodiment 3 A kind of separation and purification method of L-leucine

[0040] (1) add 22g zinc sulfate and 25mg polyacrylamide in every liter of fermentation broth, let stand, centrifuge to obtain supernatant for subsequent use;

[0041] (2) The pH value of the supernatant was adjusted to 2.0, and sodium chloride was added to make the sodium chloride concentration reach 0.30 g / ml, then L-leucine seed crystals were added, and the precipitate was separated by standing at 4°C for 24 hours;

[0042] (3) Add 20 times of water at 80°C to dissolve the precipitate, add 5% of the solution volume of activated carbon to decolorize for 1.5h, after centrifugation, adjust the pH of the supernatant to 6.0, concentrate to 1 / 15 of the original volume, let stand, Precipitation of crystals;

[0043] (4) The crystals are dissolved in water, chromatographed by D113 cation exchange resin, eluted with 2 mol / L ammonia water, and the flow rate is controlled to be 3 ml / min. The eluate is coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com