Method for realizing one-pot synthesis of pH and temperature double-sensitive ionic micro hydrogel

A dual-sensitive, ionic technology, applied in the field of environment-sensitive polymer materials, can solve the problems of cumbersome preparation methods, wide particle size distribution, and complicated purification process, and achieve convenient purification process, simple reaction operation, simple and controllable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 0.23g of temperature-sensitive monomer N-isopropylacrylamide (NIPAm), 0.028g of pH-sensitive monomer N-vinylimidazole (VIM), and 0.033g of dihaloalkane 1,4-dibromobutane were dissolved in desiccant In ionized water, stir under nitrogen atmosphere to make it fully dissolve, then add 0.025g initiator 2,2'-azobisisobutylamidine dihydrochloride, stir well, and carry out the following respectively under nitrogen atmosphere Subsequent processing:

[0037] (1) React at a constant temperature in an oil bath at 60°C for 6 hours. After dialysis and purification for 3 days, add 0.06g of organic cationic salt compound potassium fluoroborate for ion exchange reaction. The ion exchange reaction temperature is 25°C and the reaction time is 24 hours ; Then perform centrifugal washing to obtain pH and temperature dual sensitive ionic micro-hydrogel; or,

[0038] (2) React at a constant temperature in an oil bath at 70°C for 6 hours. After dialysis and purification for 3 days, add 0.06...

Embodiment 2

[0042] 0.23g temperature-sensitive monomer N-isopropylacrylamide (NIPAm), 0.028g pH-sensitive monomer N-vinylimidazole (VIM) and a certain amount of dihaloalkane 1,4-dibromobutane were dissolved in In deionized water, stir under nitrogen atmosphere to make it fully dissolved, then add 0.025g initiator 2,2'-azobisisobutylamidine dihydrochloride, stir well, under nitrogen atmosphere, at 70° Constant temperature reaction under C oil bath for 6 hours, after 3 days of dialysis and purification, add a certain amount of organic cationic salt compound to carry out ion exchange reaction, the ion exchange reaction temperature is 25 ℃, and the reaction time is 24 hours; Then carry out centrifugal washing, namely obtain An ionic microhydrogel with dual sensitivity to pH and temperature; the contents of 1,4-dibromobutane and organic cationic salts added are the following types, and the subsequent treatments are as follows:

[0043] or ,

[0044] or ,

[0045] (3) 0.033g of 1,4-dibromob...

Embodiment 3

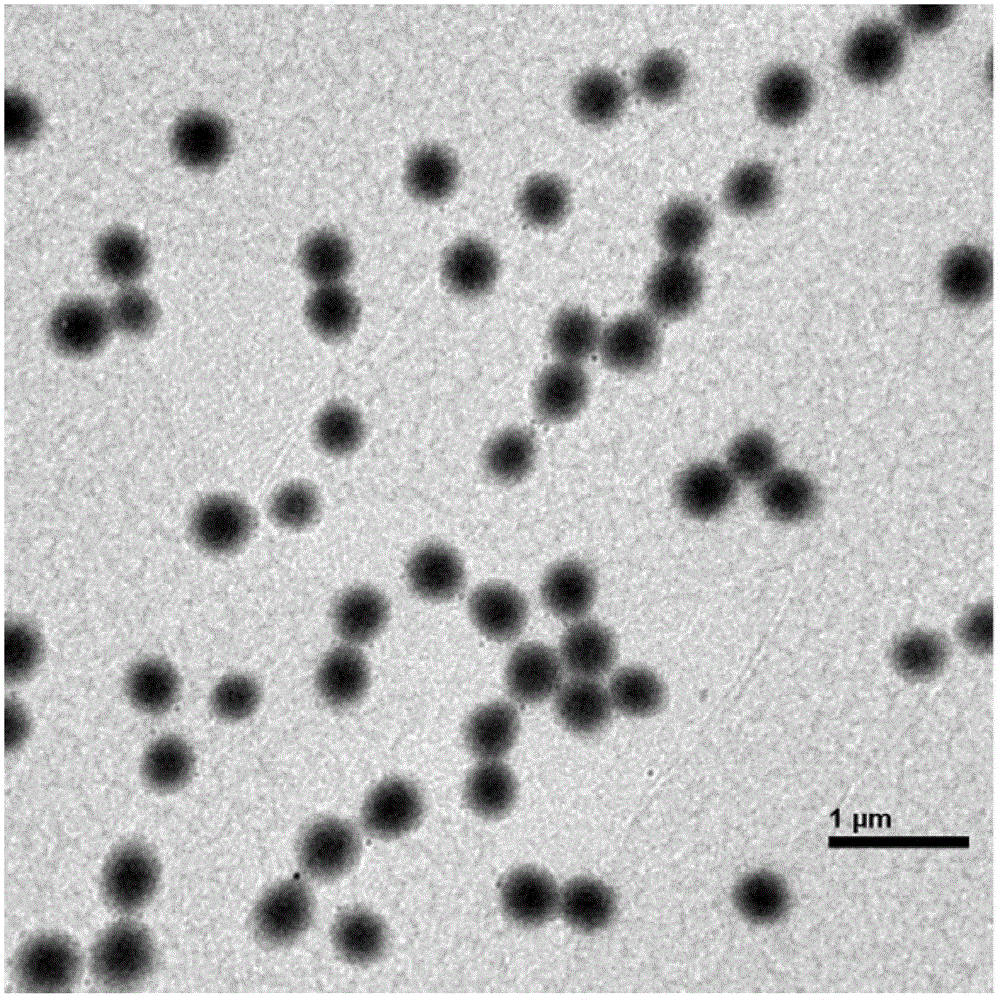

[0048] 0.23g of temperature-sensitive monomer N-isopropylacrylamide (NIPAm), 0.028g of pH-sensitive monomer N-vinylimidazole (VIM) and 0.011g of dihaloalkane 1,4-dibromobutane were dissolved in desiccant In deionized water, stir under nitrogen atmosphere to make it fully dissolved, then add 0.025g initiator 2,2'-azobisisobutylamidine dihydrochloride, stir well, and place at 70°C under nitrogen atmosphere Reaction at constant temperature under the bath for 6 hours, after dialysis and purification for 3 days, add 0.023g lithium fluoroborate for ion exchange reaction, the ion exchange reaction temperature is 25°C, and the reaction time is 24 hours; then perform centrifugal washing to obtain pH and temperature double sensitive The ionic microhydrogel; the scanning electron micrograph of the pH and temperature dual-sensitive microhydrogel obtained by the copolymerization reaction is as follows Figure 4 As shown, the particle size is 50 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com