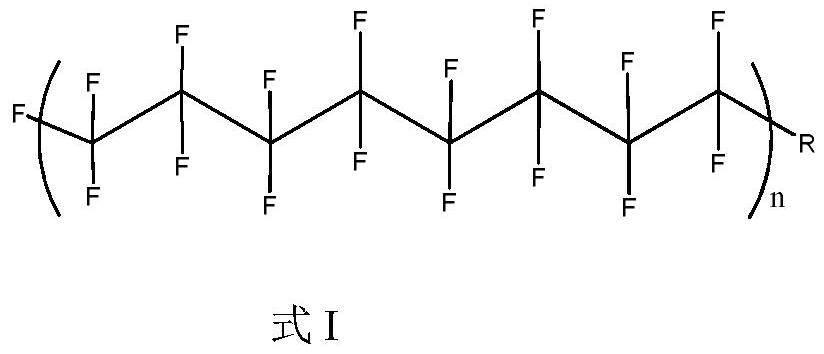

A kind of epoxy resin for hydrophobic outdoor electrical insulation and preparation method thereof

An epoxy resin and electrical insulation technology, which is applied in the field of epoxy resin for hydrophobic outdoor electrical insulation and its preparation, can solve problems such as the influence of production stability, achieve reasonable chemical structure design, controllable process, crack resistance and The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

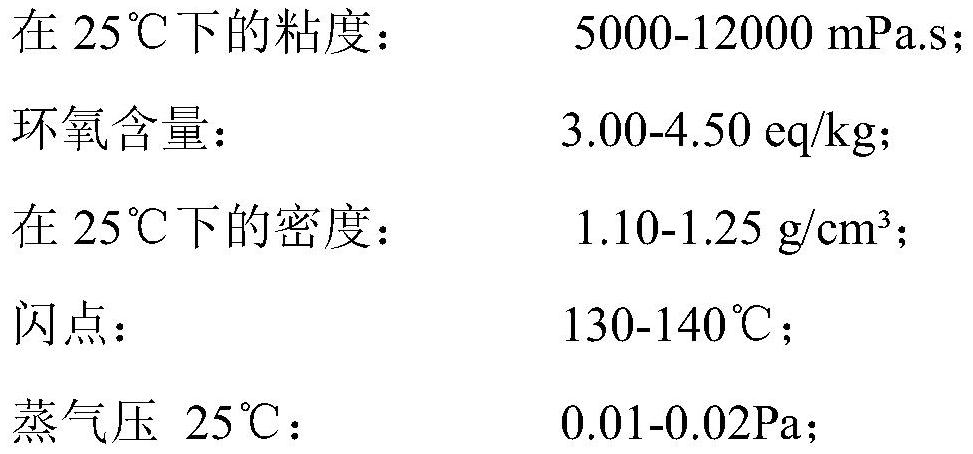

Embodiment 1

[0056] 98 grams of diglycidyl hexahydrophthalate and 0.01 grams of sulfonated castor oil were added to the reactor equipped with a vacuum system, a feeding system, a heating and cooling system and a stirring system, and the vacuum was evacuated to the maximum negative pressure, and then charged. Nitrogen was introduced to ensure an oxygen-free state in the reactor. Then, in a nitrogen atmosphere, the temperature was raised to 160°C, while 2 g parts of 2-(3-perfluorooctyl)propoxy-1,2,3-propanetricarboxylic acid were added at a constant rate through the feeding system, maintaining The reaction temperature was carried out for about 3 hours to obtain a fluorine compound-modified epoxy resin with an epoxy value of 0.48. Then add 8 grams of hydroxy silicone oil (viscosity about 1000mPa) and sodium methoxide methanol solution of the above-mentioned total amount at a constant speed through the feeding system, keep the temperature reaction for 2 hours, cool to 60 ° C, and add a total a...

Embodiment 2

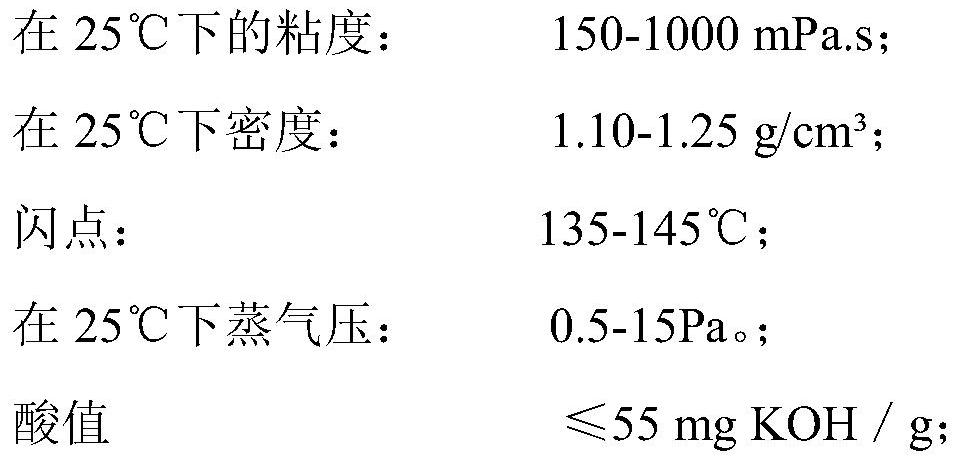

[0058] 90 grams of diglycidyl hexahydrophthalate and 0.01 grams of 2-phenylimidazole solution were added to the reactor equipped with a vacuum system, a feeding system, a heating and cooling system and a stirring system, and vacuumed to the maximum negative pressure, Nitrogen was then charged to ensure an oxygen-free state in the reactor. Then, in a nitrogen atmosphere, the temperature was heated to 150 ° C, and 10 grams of C8-C14 perfluoroalkyl ethanol was added at a constant speed through the feeding system, and the reaction temperature was maintained for about 3 hours to obtain a modified fluorine compound with an epoxy value of 0.40. epoxy resin. Then, 8 mass % methylphenylsiloxane (DC-3074) and 0.1 g of tetraisopropyl titanate (TIPI) were added at a constant speed through the feeding system, and the temperature was kept for 2 hours, and then cooled to 60 °C. ℃, and adding a total amount of 0.1% by mass of a leveling agent, a defoaming agent, etc., to obtain a hydrophobic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com