Method for improving removal rate of COS and CS2 in natural gas

A natural gas, removal rate technology, applied in CS2 removal rate, improving COS field in natural gas, can solve the problems that absorption-hydrolysis-absorption cannot be used, and it is inconvenient to build new devices, so as to increase the load of the absorption device and reduce the total Sulfur, the effect of improving the degree of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

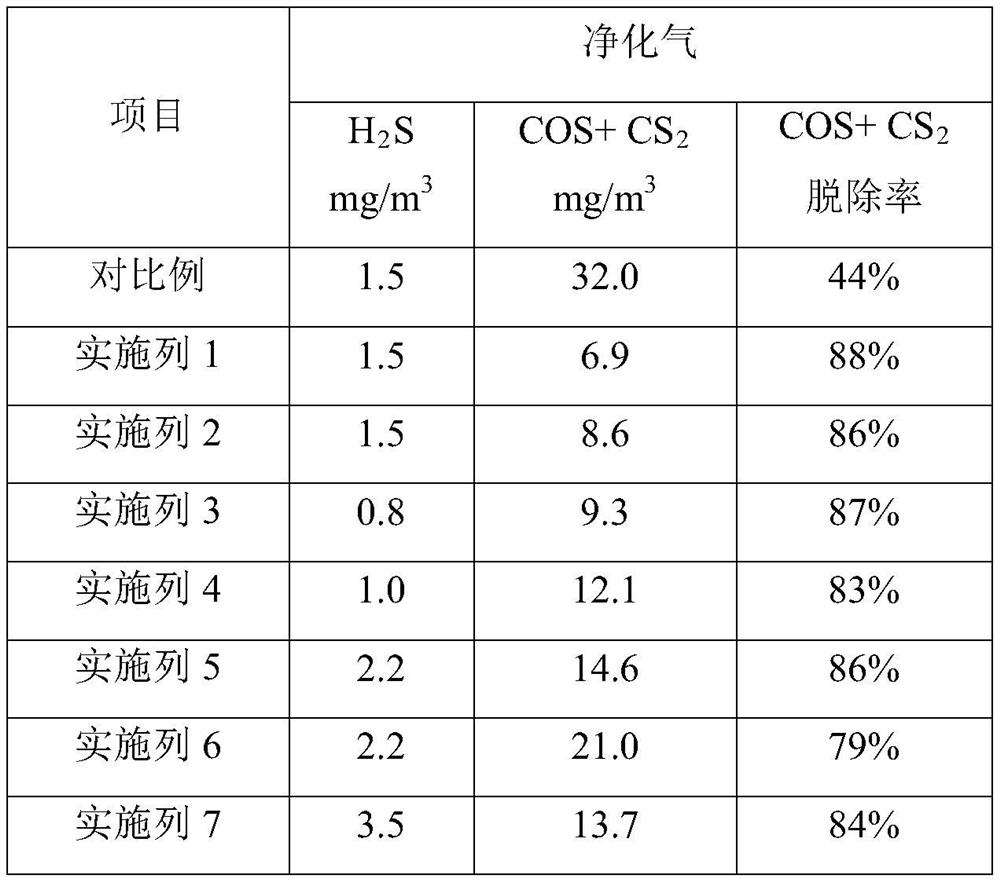

[0029] The test raw material gas and conditions are the same as those of Comparative Example 1, but the filler is loaded with COS and CS by deposition 2 Catalyst packing. The test results are shown in Table 1.

Embodiment 2

[0031] The test raw material gas and conditions are the same as those of Comparative Example 1, but the filler is loaded with COS and CS with a thickness of 50um by impregnation method 2 Catalyst coating. The test results are shown in Table 1.

Embodiment 3

[0033] The pressure of the natural gas used in the test is 2.0MPa, it enters the test device at room temperature, and the volume fraction of the main component of the natural gas is H 2 S 1.0%, CO 2 5.0%, COS 30ppmv, CS 2 20ppmv, the rest is methane. The filler is loaded with COS and CS by deposition 2 Catalyst packing. Other operating conditions are the same as in Comparative Example 1. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com