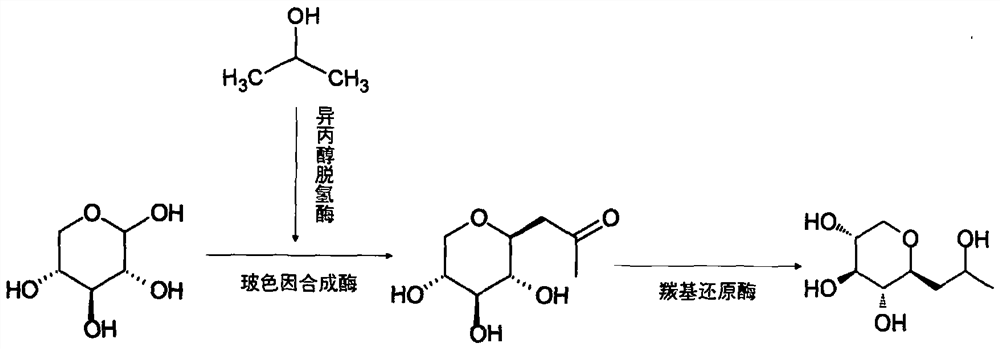

Method for preparing pro-xylane from biological enzyme by one-pot method

A technology of biological enzyme and boson, which is applied in the field of enzyme engineering to achieve the effect of safe environment, simple, reliable and direct method, and beneficial to industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A one-pot method for preparing Boseine using biological enzymes, the method includes the following steps:

[0018] (1) Preparation of substrate solution: Dissolve 100g of xylose in 1L of pH 6.0 0.1mM phosphate buffer to make the concentration of xylose 100g / L, and then add isopropanol to make the concentration of isopropanol 50g / L, and stir well.

[0019] (2) Enzyme-catalyzed preparation of Bosein: Add 10g / L biological enzyme preparation to the substrate solution. In biological enzyme preparations, isopropanol dehydrogenase, Bosein synthase, and carbonyl reductase, the mass composition ratio of these three enzyme powders is 1:1:1. At the same time, the coenzyme nicotinamide adenine dinucleotide was added to make its concentration 10mM. The conditions of the catalytic reaction were: the temperature was 30°C, the stirring speed was 50 rpm, and the reaction time was 24 h.

[0020] (3) Ultrafiltration to remove enzymes: the step (2) enzyme-catalyzed reaction solution is subjec...

Embodiment 2

[0025] A one-pot method for preparing Boseine using biological enzymes, the method includes the following steps:

[0026] (1) Preparation of substrate solution: Dissolve 200g of xylose in 1L of pH7.0 0.1mM phosphate buffer to make the concentration of xylose 200g / L, and then add isopropanol to make the concentration of isopropanol 100g / L, and stir well.

[0027] (2) Enzyme-catalyzed preparation of Bosein: Add 20g / L biological enzyme preparation to the substrate solution. In biological enzyme preparations, isopropanol dehydrogenase, Bosein synthase, and carbonyl reductase, the mass composition ratio of these three enzyme powders is 1:2:1. At the same time, the coenzyme nicotinamide adenine dinucleotide was added to make its concentration 20mM. The conditions of the catalytic reaction were as follows: the temperature was 35°C, the stirring speed was 100 rpm, and the reaction time was 36 h.

[0028] (3) Ultrafiltration to remove enzymes: the step (2) enzyme catalyzed reaction soluti...

Embodiment 3

[0033] A one-pot method for preparing Boseine using biological enzymes, the method includes the following steps:

[0034] (1) Preparation of substrate solution: Dissolve 100g of xylose in 1L of pH7.0 0.2mM phosphate buffer to make the concentration of xylose 100g / L, and then add isopropanol to make the concentration of isopropanol 100g / L, and stir well.

[0035] (2) Enzyme-catalyzed preparation of Bosein: Add 20g / L of biological enzyme preparation to the substrate solution. In biological enzyme preparations, isopropanol dehydrogenase, Bosein synthase, and carbonyl reductase, the mass composition ratio of these three enzyme powders is 1:0.5:1. At the same time, the coenzyme nicotinamide adenine dinucleotide was added to make its concentration 20mM. The catalytic reaction conditions are: temperature is 35°C, stirring speed is 50 rpm, and reaction time is 36 h.

[0036] (3) Ultrafiltration to remove enzymes: the step (2) enzyme-catalyzed reaction solution is subjected to ultrafiltra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com