Textile processing fiber type opener

An opener and fiber technology, applied in the field of fiber openers for textile processing, can solve problems such as affecting the quality of fabrics, accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

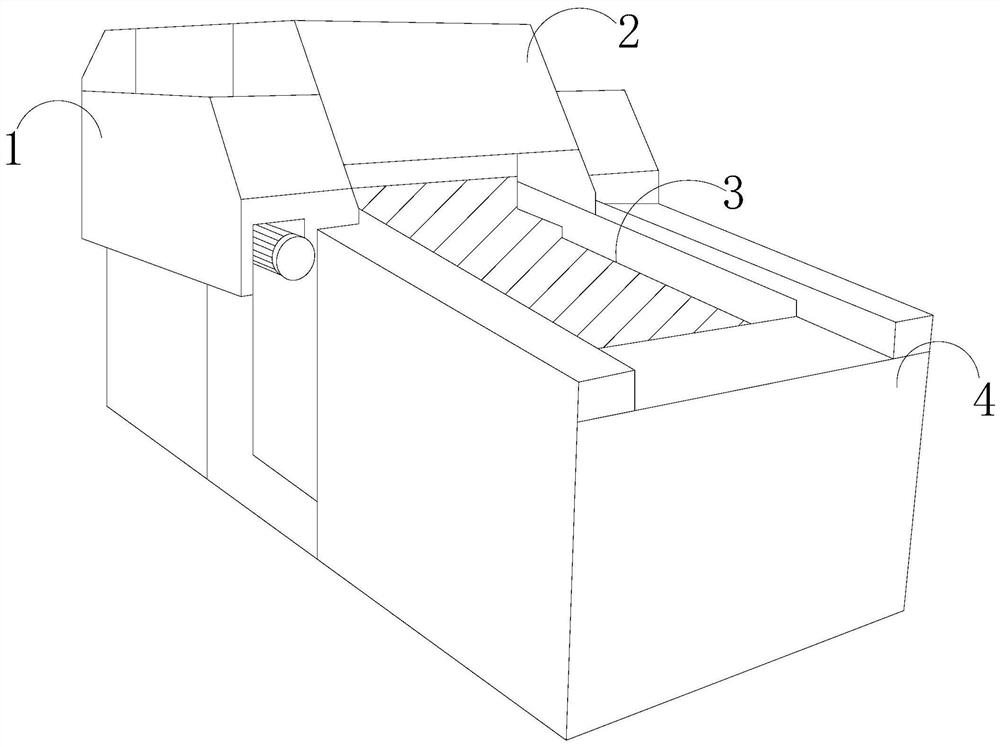

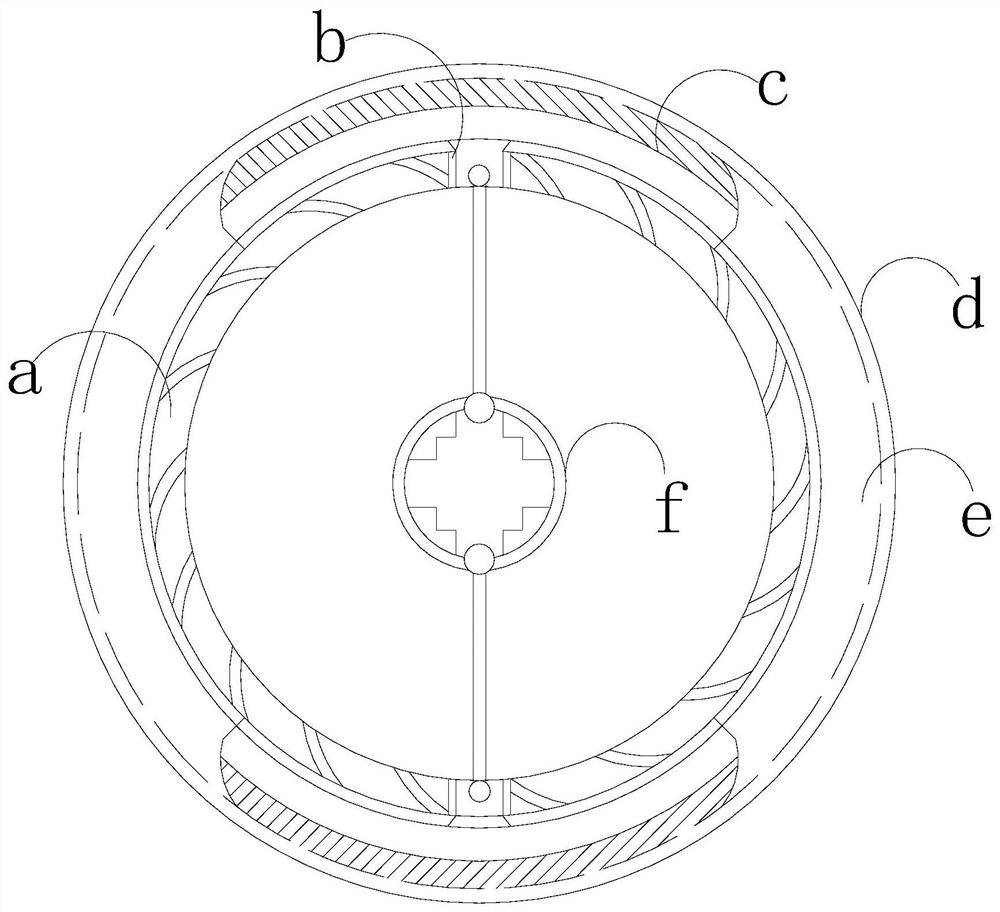

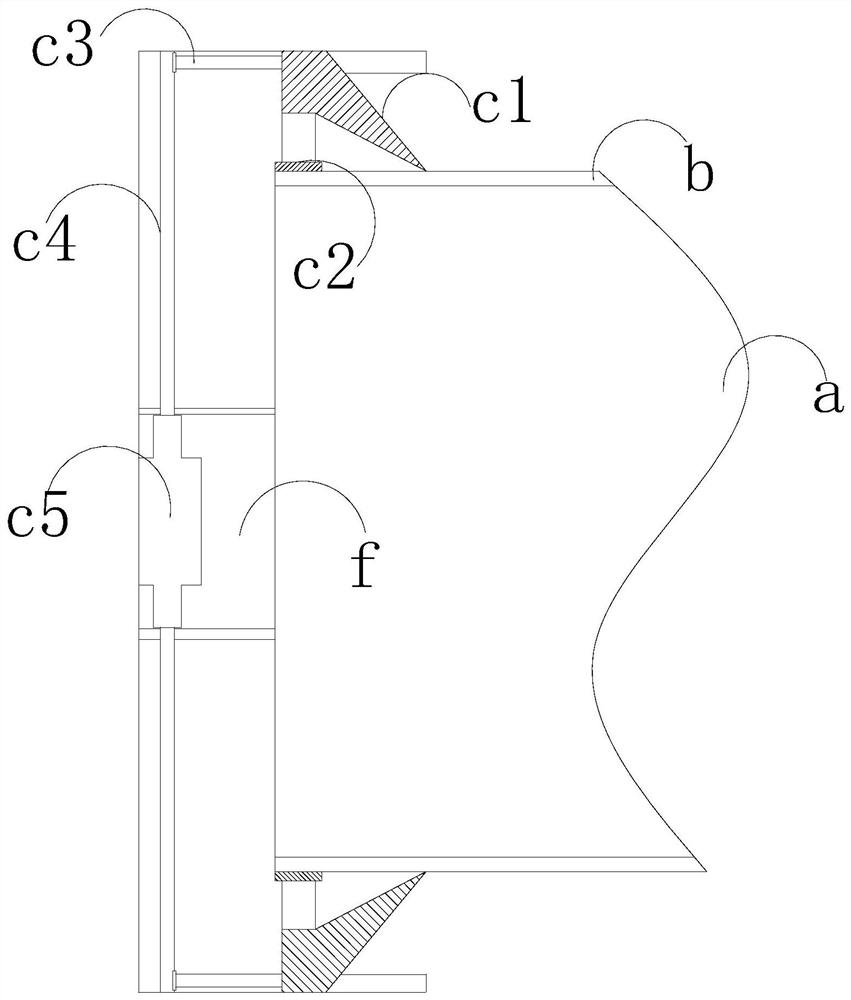

[0024] Such as Figure 1-Figure 5 As shown, the present invention provides a kind of textile processing fiber type opener, its structure comprises driving box 1, dustproof cover 2, conveyer belt 3, cabinet 4, and described driving box 1 is installed on the outside of cabinet 4, between the two Using electrical connection, the dustproof cover 2 is set on the chassis 4, the conveyor belt 3 is installed on the chassis 4, the inside of the drive box 1 is provided with a drive motor, and the drive motor drives the conveyor belt 3. The inside of the dust cover 2 is provided with a roll a, which is located above the conveyor belt 3, and the roll a is provided with a roll groove b, a cleaning mechanism c, a side cover d, an embedded cavity e, and a roller f. The roll groove b is movably coordinated with the cleaning mechanism c, the cleaning mechanism c is arranged inside the side cover d, an embedded cavity e is provided between the side cover d and the roll a, and the cleaning mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com