Assembling and debugging method for improving producibility of high-frequency coaxial circulator/isolator

A debugging method and circulator technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problems of high-frequency coaxial circulators/isolators, such as easy production, poor consistency, and low debugging efficiency, so as to improve debugging Efficiency, easy debugging, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: see Figure 1 to Figure 9 , an assembly and debugging method for improving the productivity of a high-frequency coaxial circulator / isolator, comprising the following steps:

[0034] (1) film arrangement;

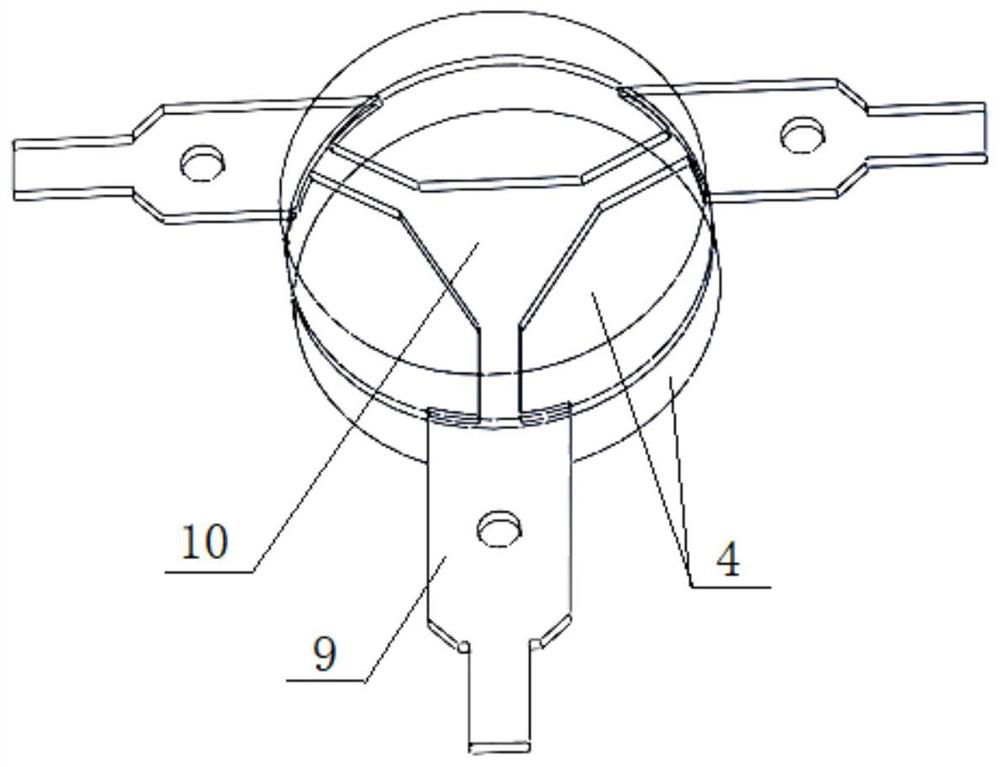

[0035] Substrate 4 and central conductor 5 form a unit group in the order of substrate 4+central conductor 5+substrate 4, and a plurality of unit groups are arranged on the positioning jig, and the positioning jig is used to make each unit group The substrate 4 and the central conductor 5 are coaxial, and each unit group is coaxial, and the central conductor 5 includes a central junction 10 and three ports;

[0036] (2) Bonding and shaping;

[0037] Compress multiple unit groups with a positioning fixture, and bond and fix the substrate 4 and the central conductor 5 in each unit group by glue;

[0038] (3) Prepare the cavity of the circulator / isolator, and the cavity is provided with a debugging hole 13 corresponding to the three ports 9; specifically...

Embodiment 2

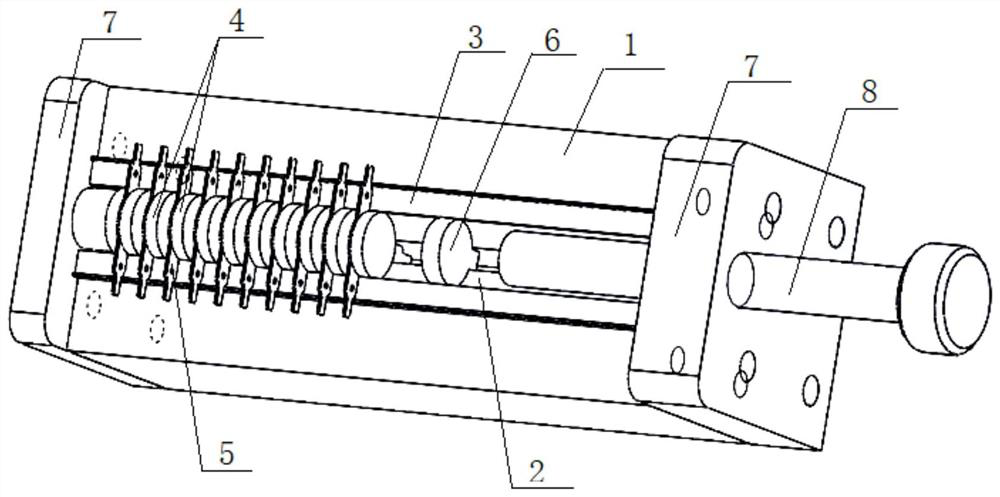

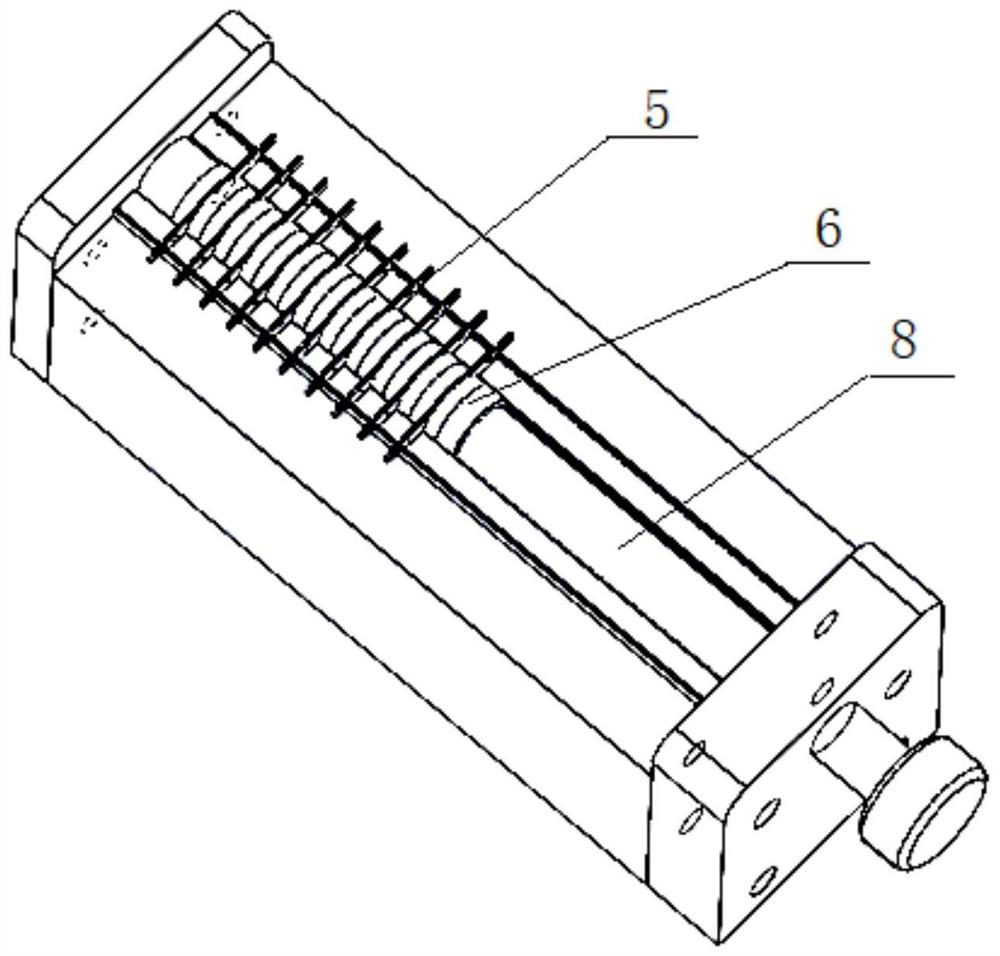

[0040] Embodiment 2, for embodiment 1, we provide a kind of specific structure of positioning fixture, described positioning fixture comprises a cuboid positioning groove 1, and the upper surface of described positioning groove 1 is provided with strip groove along its length direction 2. The cross section of the strip-shaped groove 2 matches the substrate 4, and is used to place the substrate 4 and position it. The bottom and both sides of the strip-shaped groove 2 are provided with three strips along its length direction for placing the central conductor 5. The port 9 slot 3 of the port 9, when the central junction 10 is located in the bar-shaped slot 2, the three ports 9 are just located in the three port 9 slots 3 and positioned, and the positioned substrate 4 and the central conductor 5 are coaxial;

[0041] There is a polysulfone anti-rotation piece 6 inside the positioning groove 1, the cross section of the polysulfone anti-rotation piece 6 matches the strip groove 2, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com