Full-automatic production line for HDMI high-definition transmission line

A high-definition transmission line, fully automatic technology, applied in circuit/collector parts, electrical components, circuits, etc., can solve problems such as low production efficiency, and achieve the effect of improving efficiency, saving time, and reducing equipment space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

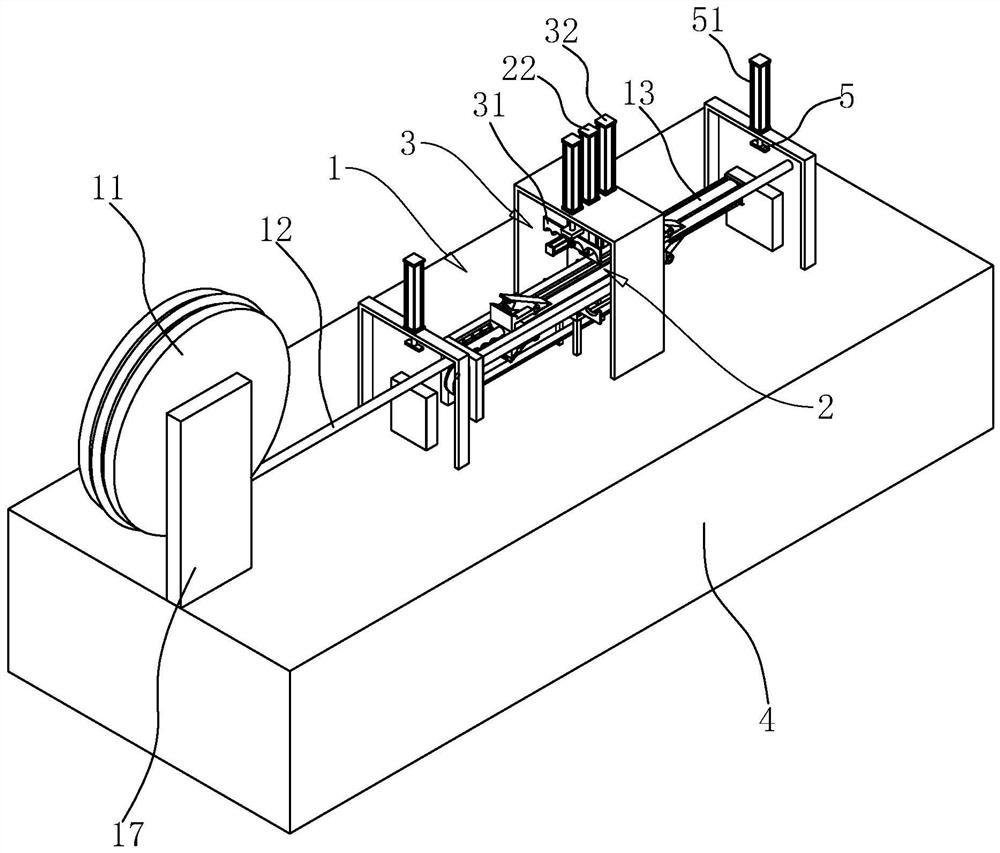

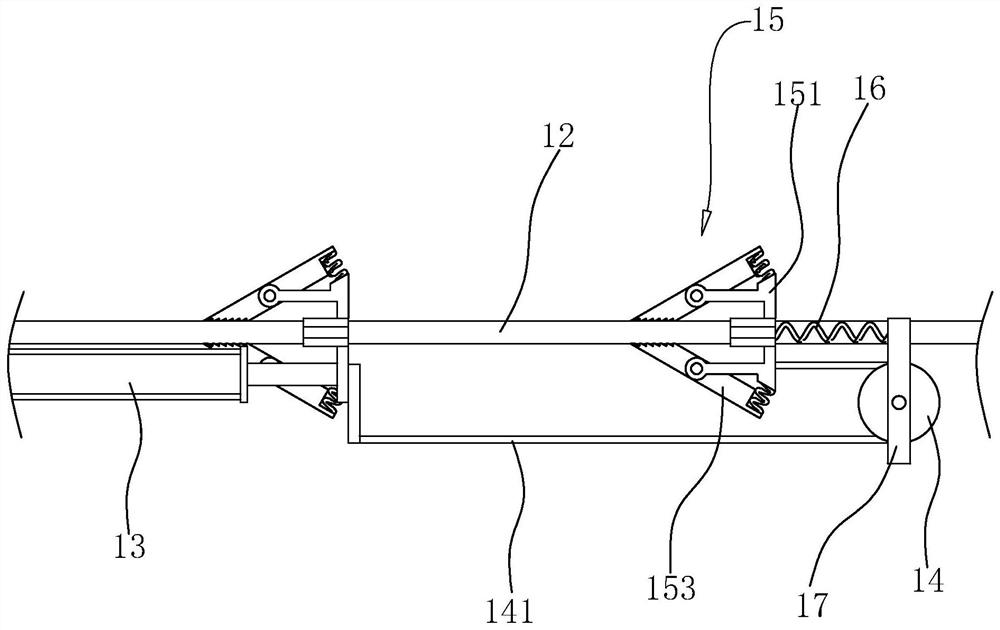

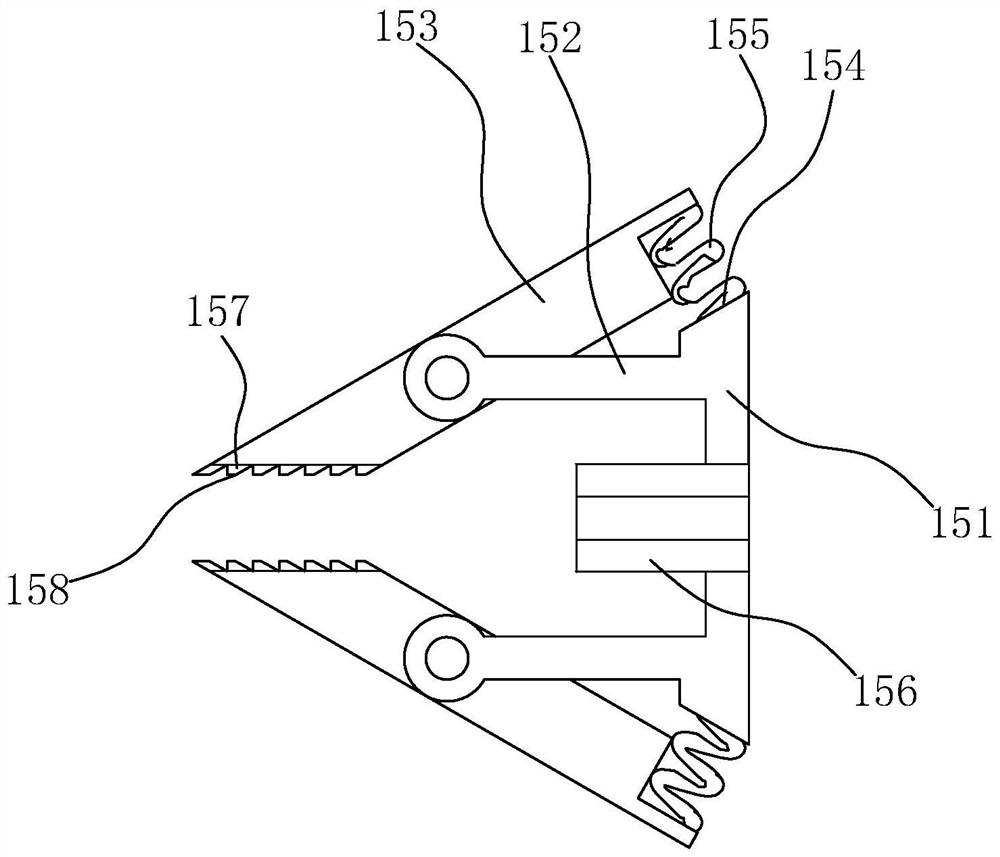

[0034] The following is attached Figure 1-4 The application is described in further detail.

[0035] In the production process of HDMI high-definition transmission line, it usually needs to go through processes such as cutting, stripping, stripping, soldering, welding, testing, injecting inner film, measuring inner film, injecting shell, inspection, packaging and delivery. In the production process, a vertical molding machine is usually used to form the inner and outer membranes; welding or hot-melt equipment is used to weld wires and plugs; a punching machine is used to stamp the shell and terminals for the plug; precision The wire comprehensive tester is used for electrical testing of the wire; the wire swing testing machine is used for the basic swing frequency test; the plug-in force tester is used for the basic plug-in test;

[0036] The embodiment of the present application discloses a fully automatic production line for HDMI high-definition transmission lines. refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com